A two-way air-tight drill pipe joint with tensile bending resistance

A technology for drill pipe joints and air sealing, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc., can solve the problems of shoulder surface separation, seal failure, erosion corrosion, etc., and achieve excellent bending resistance, improved sealing reliability, The effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail by the following examples. It should be pointed out that the following examples are only to further illustrate the present invention, and can not be interpreted as limiting the protection scope of the present invention. Those skilled in the art make according to the content of the present invention Some non-essential improvements and adjustments still belong to the protection category of the present invention.

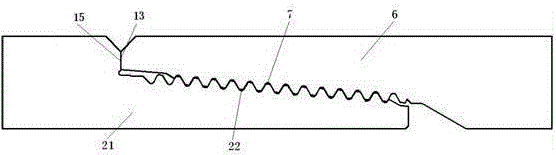

[0027] see Figure 1 to Figure 6 ,in figure 1 A schematic diagram of an API NC38 tool joint is shown.

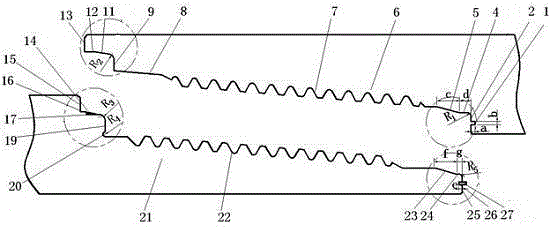

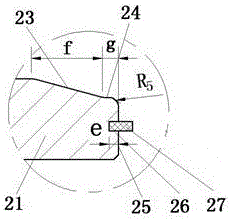

[0028] figure 2 Shown is a schematic diagram of the structure of the anti-bending two-way gas-sealed drill pipe joint of the present invention, which is composed of an internal threaded part 6 and an external threaded part 21 . It is characterized in that the internal threaded part 6 includes a first outer shoulder surface 13, a first cylindrical hole 12, a first conical hole 11 matched with a wedge-shaped rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com