Coalbed methane (CBM) cluster double multi-branch horizontal well and drilling method relative to discharging and mining vertical well system

A coalbed methane, multi-branch technology, applied in drilling equipment and methods, drilling equipment, directional drilling, etc., can solve the problems of high cost and low drilling efficiency, and achieve the effect of reducing construction period, increasing daily output and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

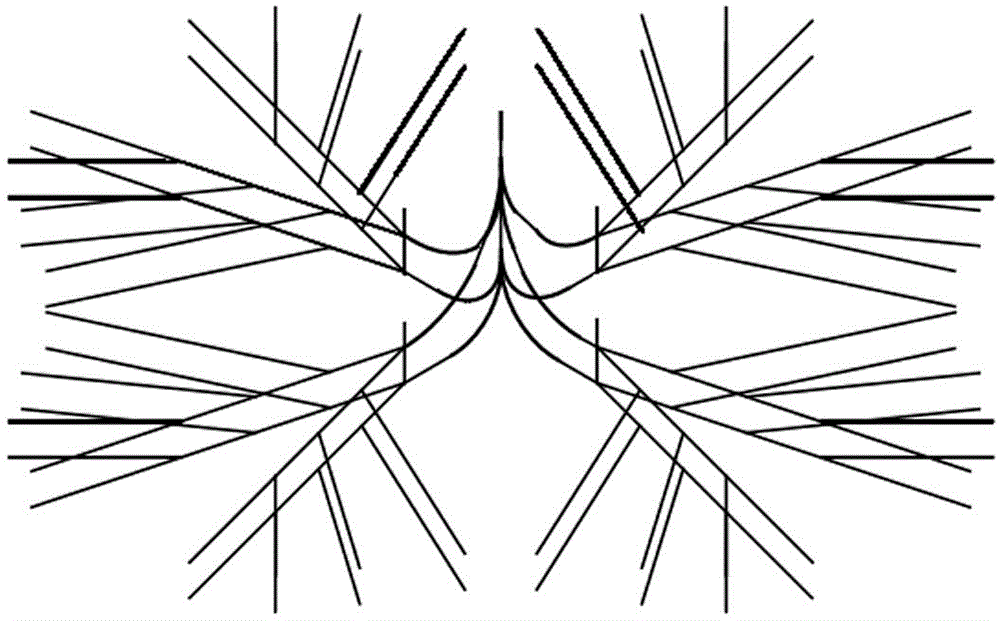

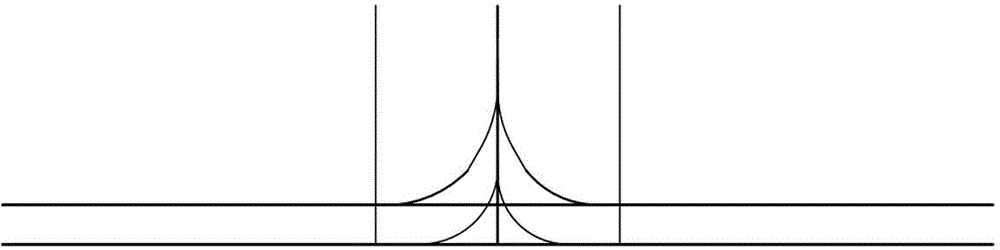

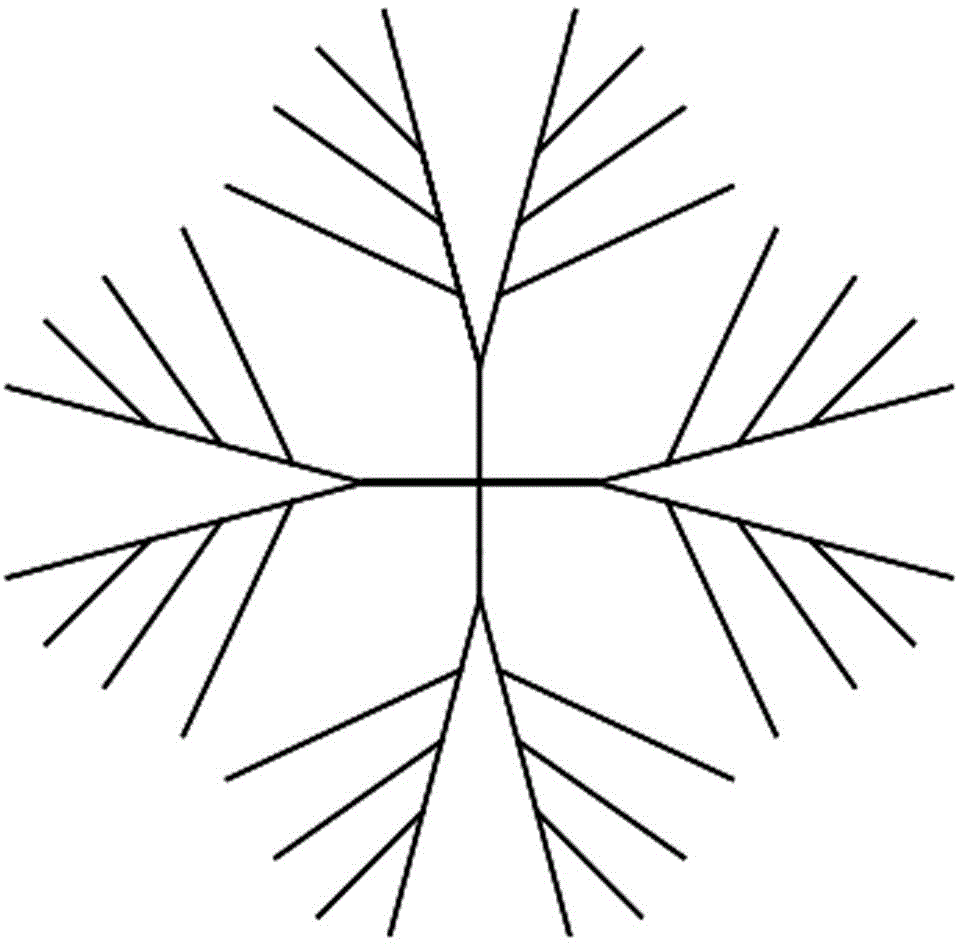

[0021] Such as Figure 1-4 As shown, the drilling method of the present invention includes the drilling of four drainage vertical wells in four directions, the completion of eight caves at the reservoir, the drilling of a cluster multi-branch horizontal well, and the long-distance drilling of the corresponding drainage vertical wells. connection; the specific steps are to determine the formation dip angles of the reservoirs in all azimuths around the main wellbore, so as to design the footage direction, footage length, and angle between branches of the horizontal section of the cluster multi-branch horizontal well. In strata, you can choose to use U-shaped horizontal wells instead of multi-branch horizontal wells in the branch direction; in fault block strata, you can choose not to drill or reduce footage, and after determining the position of each row of vertical wells, perform cluster branching in order of azimuth angles construction.

[0022] Drilling and setting vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com