Online sliding pressure optimization method for turbine of thermal power plant

An optimization method, steam turbine technology, applied to mechanical equipment, engine components, machines/engines, etc., can solve problems such as deviation from the optimal valve position, failure to consider the precise valve point sliding pressure, and failure to consider the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

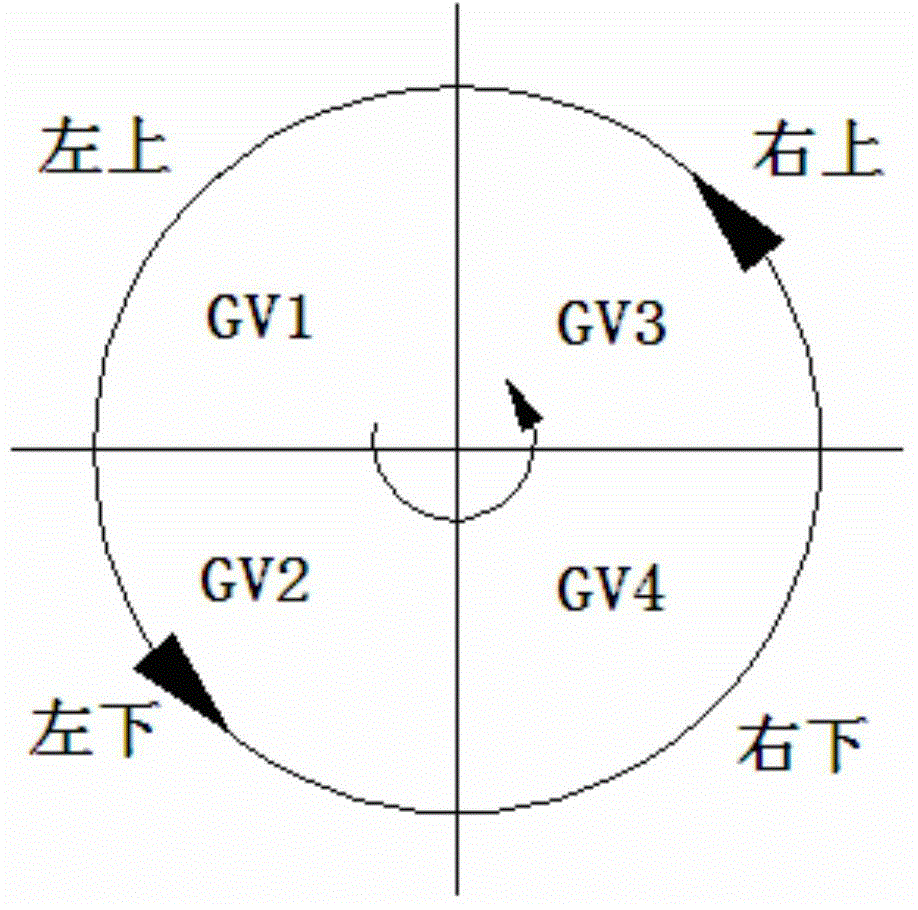

[0063] An online sliding pressure optimization method for steam turbines in thermal power plants. The valve distribution mode is changed, and the high-pressure regulating valve is changed from three-valve first-opening and two-level management to two-valve first-opening and three-level management.

[0064] The valve distribution method is changed. The 1000MW ultra-supercritical steam turbine design adopts nozzle adjustment method. There are four sets of high-pressure cylinder inlet steam nozzles, which are controlled by four high-pressure valves. The original steam distribution method with two-stage valve management and three high-pressure valves GV1, GV2, GV3 are opened first, and the fourth high-voltage regulating gate GV4 is opened again, namely GV1, GV2, GV3 (three simultaneous switches) → GV4, which is mainly designed based on the basic load of the million-kilowatt unit. The unit participates in power grid peak shaving. When the unit is under low load, the designed steam dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com