Turbine generator lubricating oil tank

A technology for steam turbine generator set and lubricating oil, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of high production equipment and technical requirements, difficult manufacturing, and inconvenient transportation, and achieves reliability and safety. The effect of high performance, convenient transportation and convenient manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to describe the technical features and functions of the present invention in detail and realize them according to the content of this specification, the implementation of the present invention will be further described below in conjunction with the accompanying drawings.

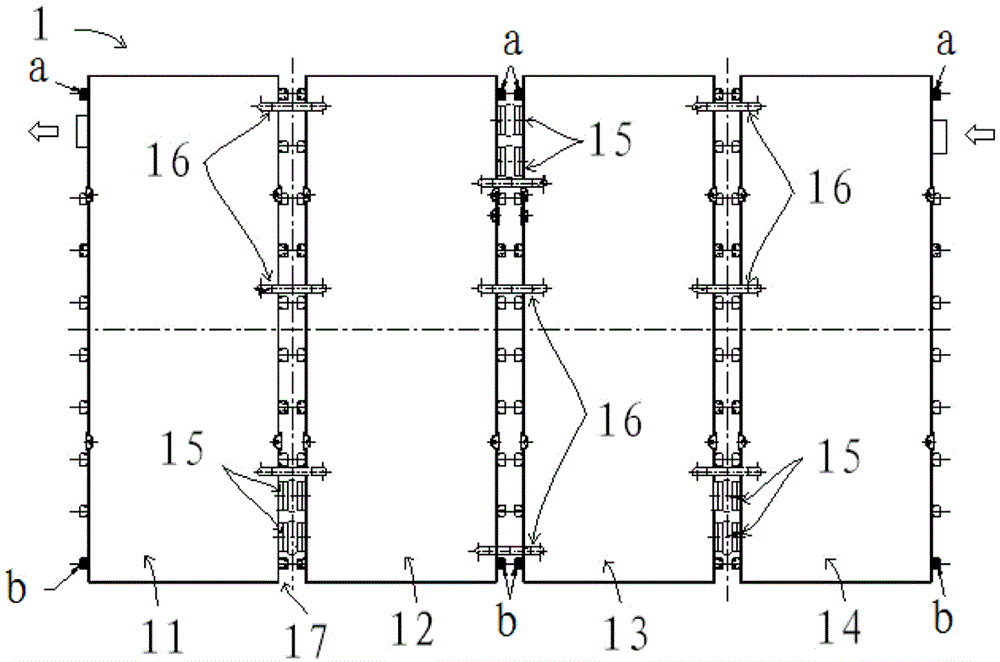

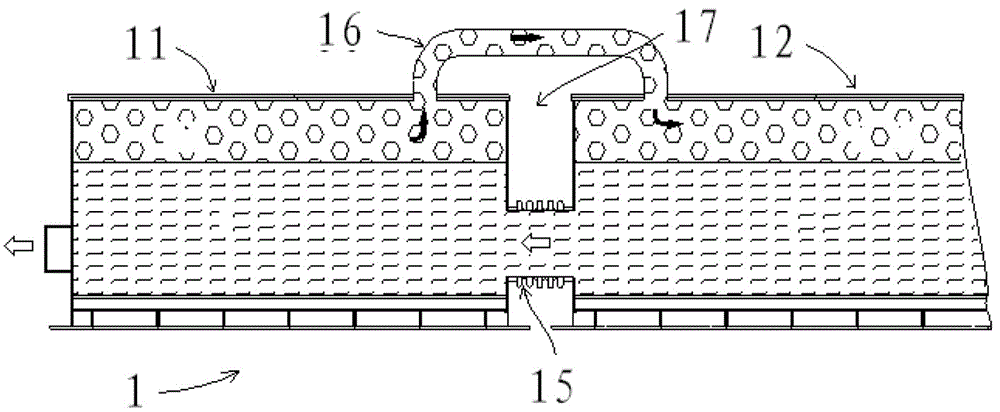

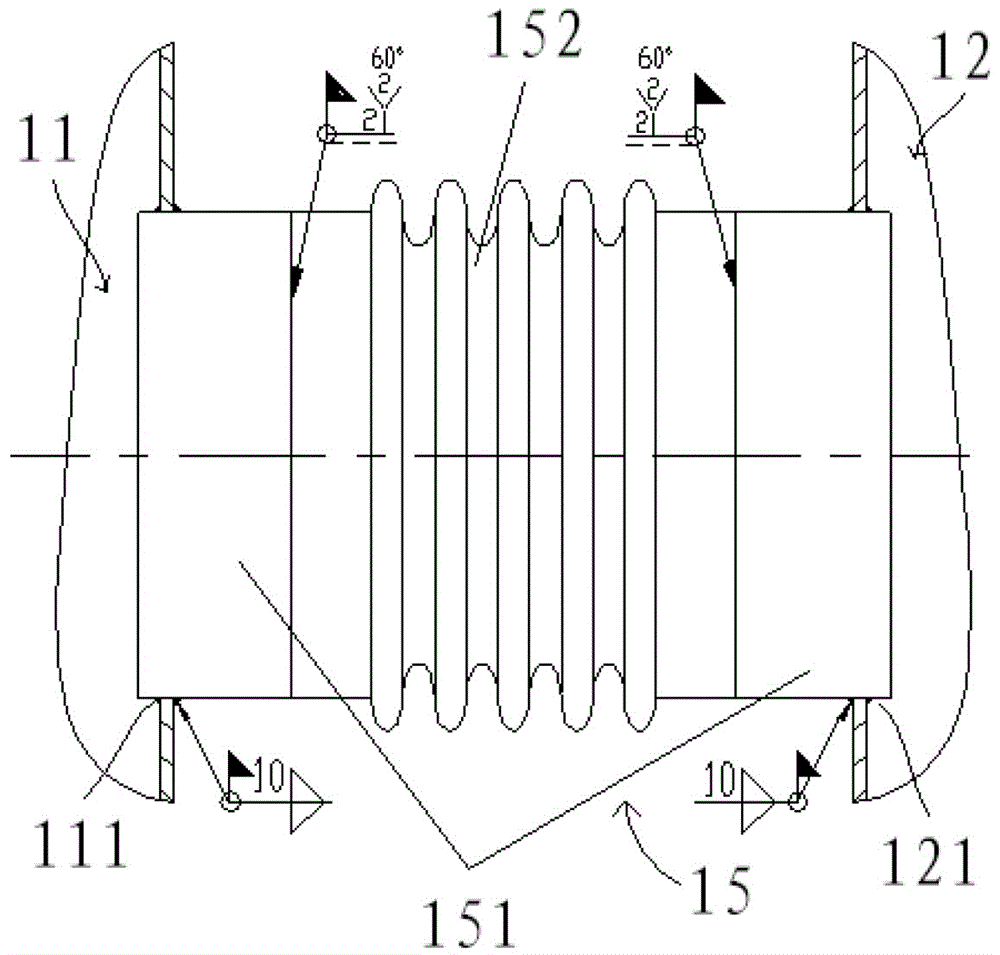

[0030] figure 1 A lubricating oil tank 1 of a turbogenerator set according to the present invention is shown, including four tank modules 11 , 12 , 13 , 14 , a first-type first flexible connection structure 15 and a first-type second flexible connection structure 16 . The four fuel tank modules 11 , 12 , 13 , 14 are all cuboid structures, but it is not understood to be limited thereto, and may also be other suitable shapes and structures, and their sizes may be all the same, or all or partly different. The structure, shape and size of the fuel tank modules 11, 12, 13 and 14 should be determined according to actual construction needs. Between the fuel tank module 11 and the fuel tank module 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com