Intelligent control system for gas-fired air heaters

An intelligent control system, gas hot blast stove technology, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of reducing the hot blast stove control system, complex control system, unsuitable for promotion, etc., to achieve accurate control, low cost, Effects suitable for promotional use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

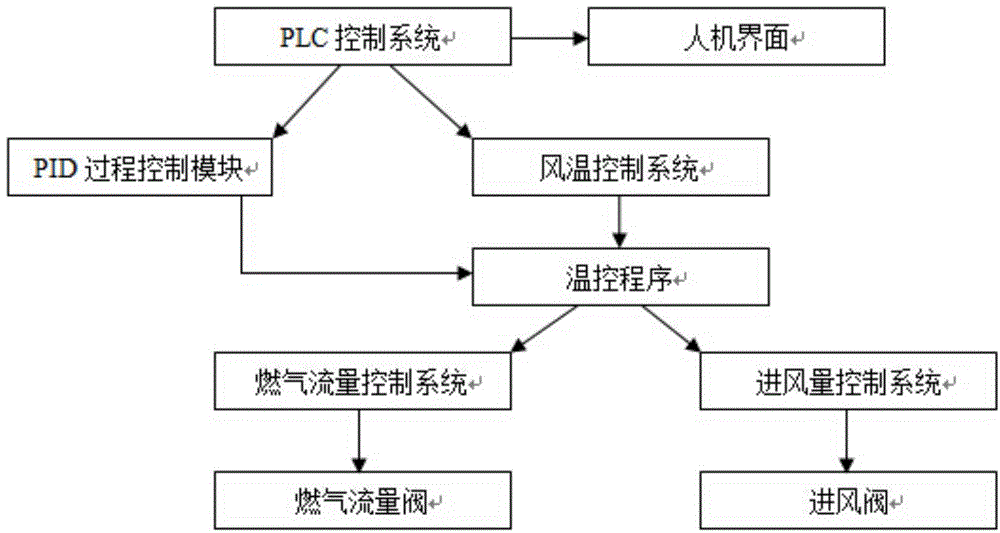

[0026] Such as figure 1 The shown intelligent control system of a gas hot blast stove includes a PLC control system with a man-machine interface, and manually inputs information such as air volume, wind temperature, and time on the man-machine interface, and the information is collected and transmitted to the PLC control system for processing. The PLC control system includes an air temperature control system and a PID process control module. The air temperature control system includes a temperature detector, a gas flow control system and an air intake control system. The gas flow control system is connected to the burner inlet The gas flow valve on the gas pipe controls the gas flow, the air intake volume control system is connected to the air intake valve arranged at the air inlet of the hot blast stove to control the air intake, and the temperature detector is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com