Air source heat pump hot-air fan with combined operating modes

A technology of air source heat pump and working mode, which is applied to air heaters, heat pumps, dryers, etc., can solve the problems of low energy efficiency ratio, reduced material drying speed, no dehumidification treatment, etc., and achieve high energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

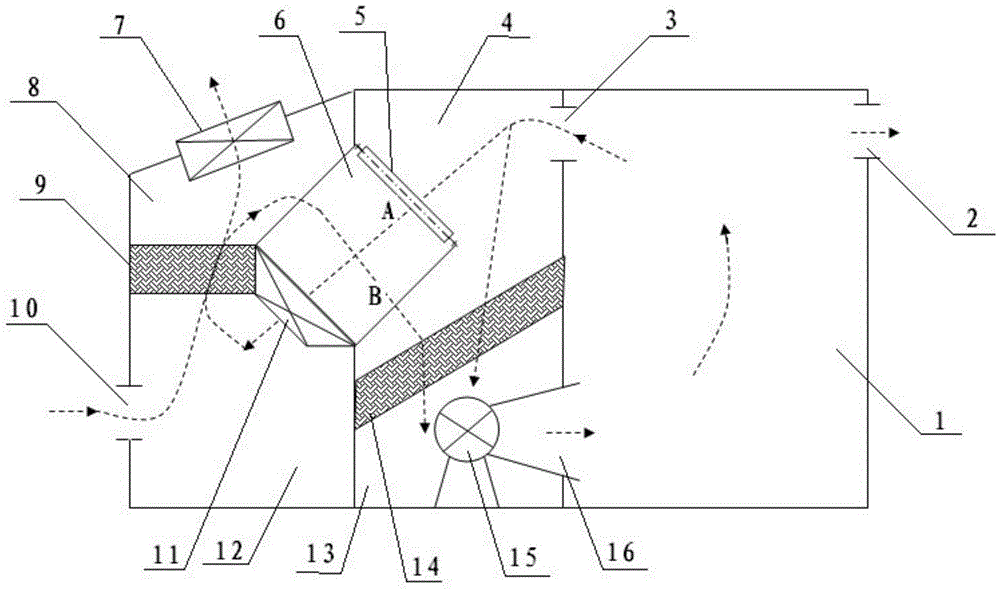

[0038] Referring to the accompanying drawings, which reflect a specific structure of the present invention, the air source heat pump hot air blower with composite working mode is connected to the drying chamber 1 and the total heat heat exchanger 6, and the casing of the air source heat pump is divided into mutual Separate first and second lumens:

[0039] The first inner chamber is divided into X chamber 8 and Y chamber 12 by evaporator 9, Y chamber 12 is provided with air inlet 10, X chamber 8 is provided with air outlet of device evaporator fan 7;

[0040] The second inner cavity is divided into an air inlet chamber 4 and an air outlet chamber 13 by a condenser 14; the air outlet chamber 13 is equipped with a condenser fan 15 and an air outlet 16, and the air outlet 16 is connected to the drying chamber 1; the air inlet chamber 4 is connected to the drying chamber 1's return air outlet 3; the drying room 1 only needs to set the moisture exhaust hole 2, and no longer needs t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com