Vertical type vacuum debinding furnace

A vacuum degreasing, vertical technology, applied in vertical furnaces, furnaces, furnace types, etc., can solve problems such as grease hanging on the wall, achieve high work efficiency, high efficiency, and improve degreasing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

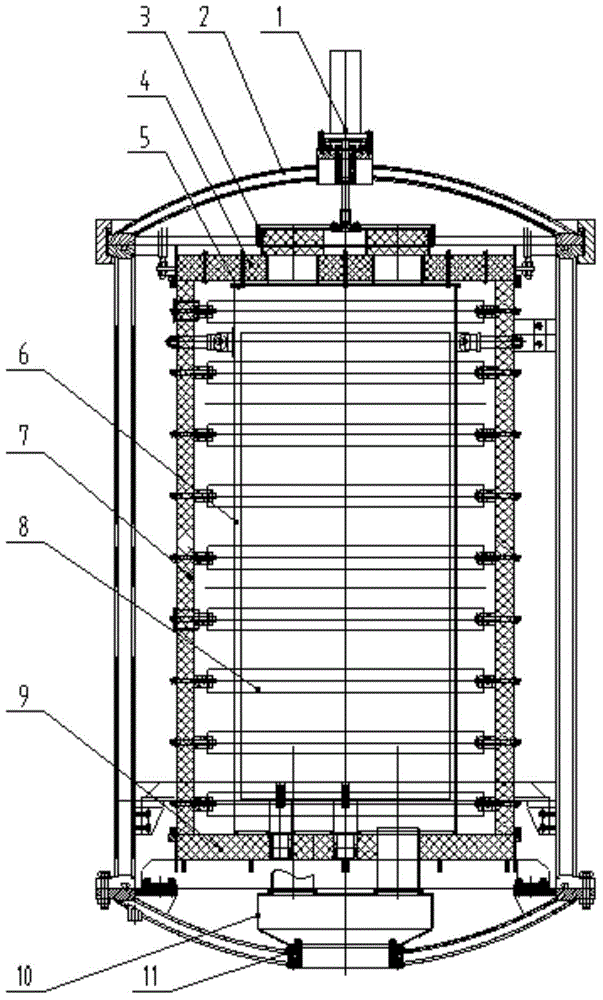

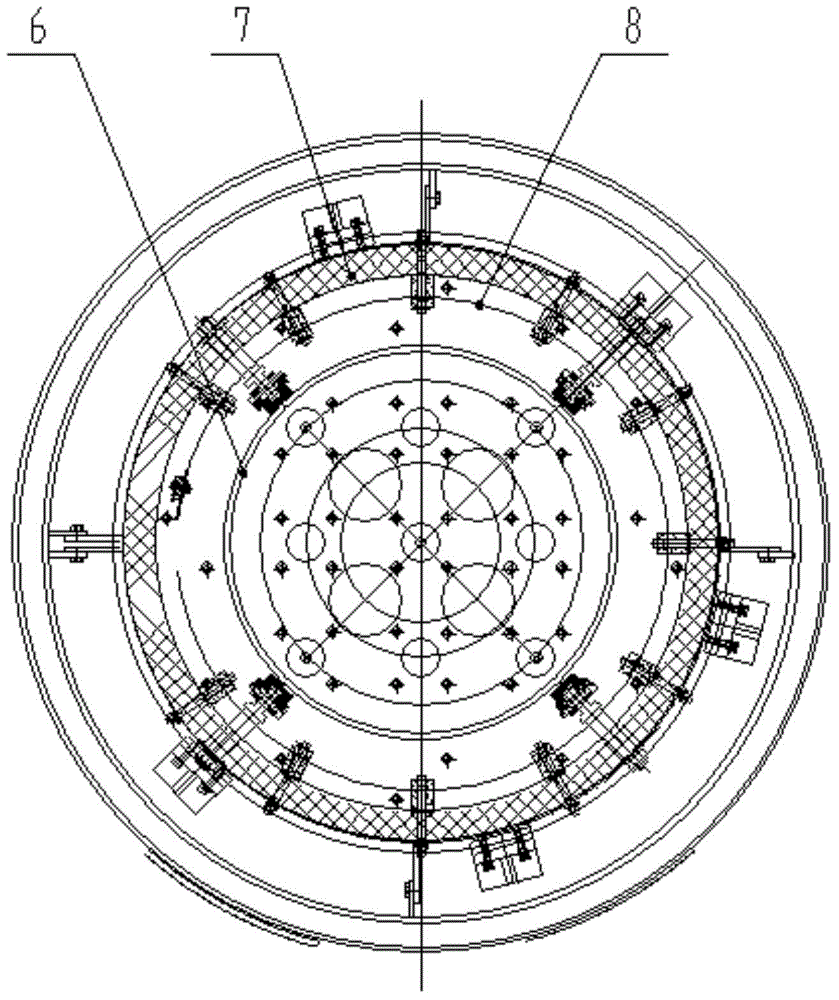

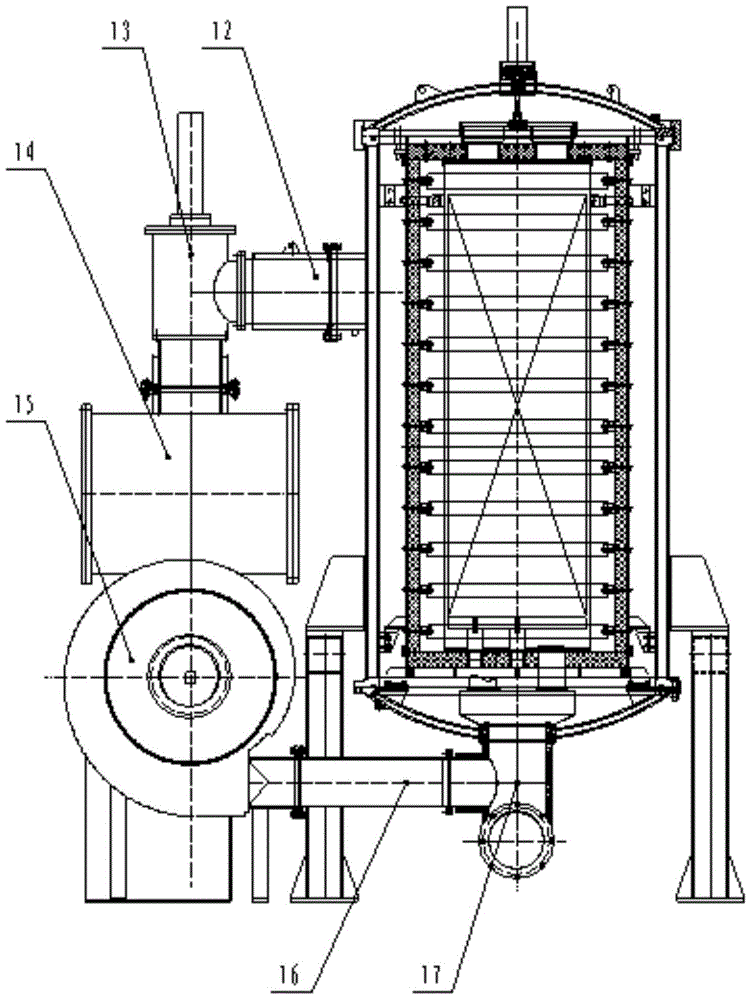

[0015] This vertical vacuum degreasing furnace of the present invention includes a program automatic control system, an air cooling system, a degreasing system, a heating electrical system, an air charging and deflation system, a water cooling system and peripheral auxiliary facilities. The furnace shell is provided with two doors, namely the furnace Shell upper cover 2 and furnace shell lower cover 11, see figure 1 , which is characterized in that a vacuum system is installed in the furnace shell of the vertical vacuum furnace, the vacuum pipeline communicates with the heating chamber 7 pipeline, and an airtight tank 6 is added in the heating chamber 7, and the heating chamber 7 and the airtight tank 6 therein are equipped with upper and lower openings , the furnace shell loam cake 2 of upper opening is inlet and outlet, and furnace shell loam cake 2 furnace inboards fix the damper 3 driven by cylinder 1, the upper screen body 4 of heating chamber and the top cover 5 of airtig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com