Real-time correction method for off-line measurement error of crystal matching angle

An offline measurement and matching angle technology, applied in the field of optical engineering, can solve the problems of no movement displacement error, crystal movement displacement error, affecting the accuracy of measurement results, etc., to ensure accuracy and eliminate dynamic measurement errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

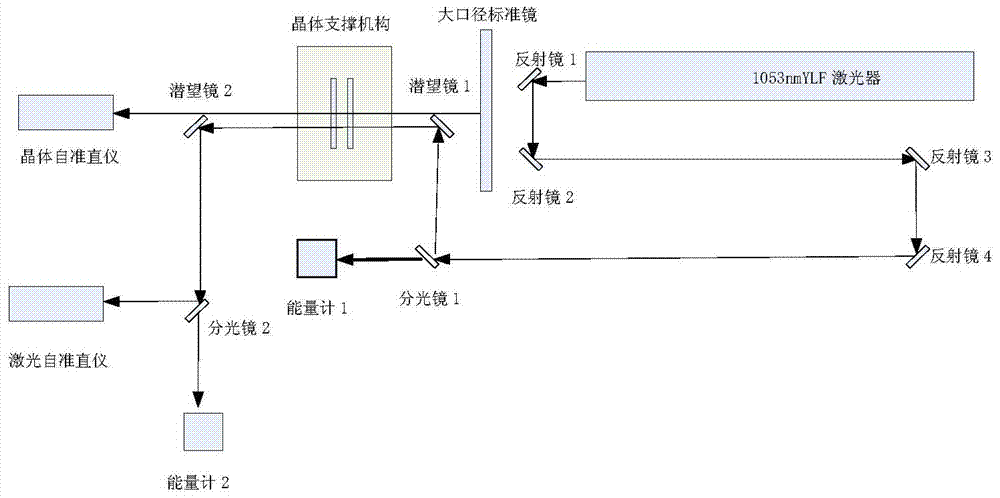

[0025] The crystal matching angle off-line measurement system adopted in the present invention is as figure 1 As shown, the system includes a laser, a beam splitter 1, a beam splitter 2, a periscope 1, a periscope 2, a large-diameter standard mirror, and a crystal to be measured. The laser is emitted from the laser, and the incident laser light is divided into two by the beam splitter 1. Beam: one beam is incident on the energy meter 1, the other beam is incident on the periscope 2 behind the crystal to be measured through the periscope 1, and the incident beam is divided into two beams by the beam splitter 2 after being reflected by the periscope 2: among them One beam is incident on the energy meter 2.

[0026] Wherein, the laser is a 1053nm laser, the model is PL3143A-2-DPSS, and the main perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com