Method for processing static fusion welding force data of electrical contact material based on Weibull distribution

A technology of electrical contact materials and Weibull distribution, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of data singleness and shorten the experiment time, and achieve high fitting accuracy, shorten the test time, The effect of saving test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

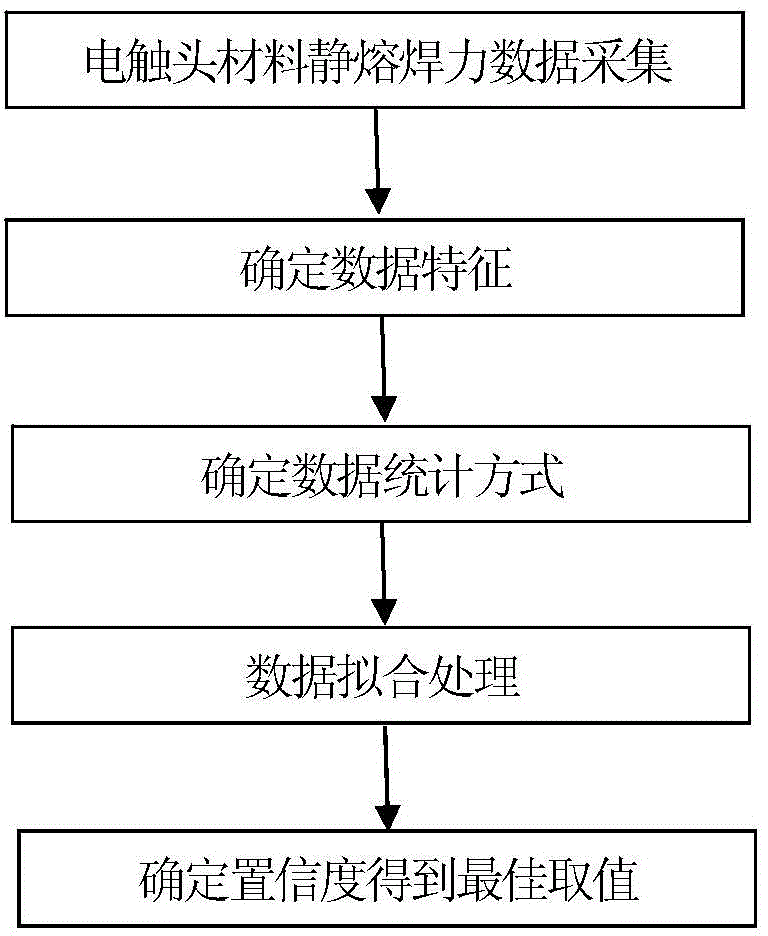

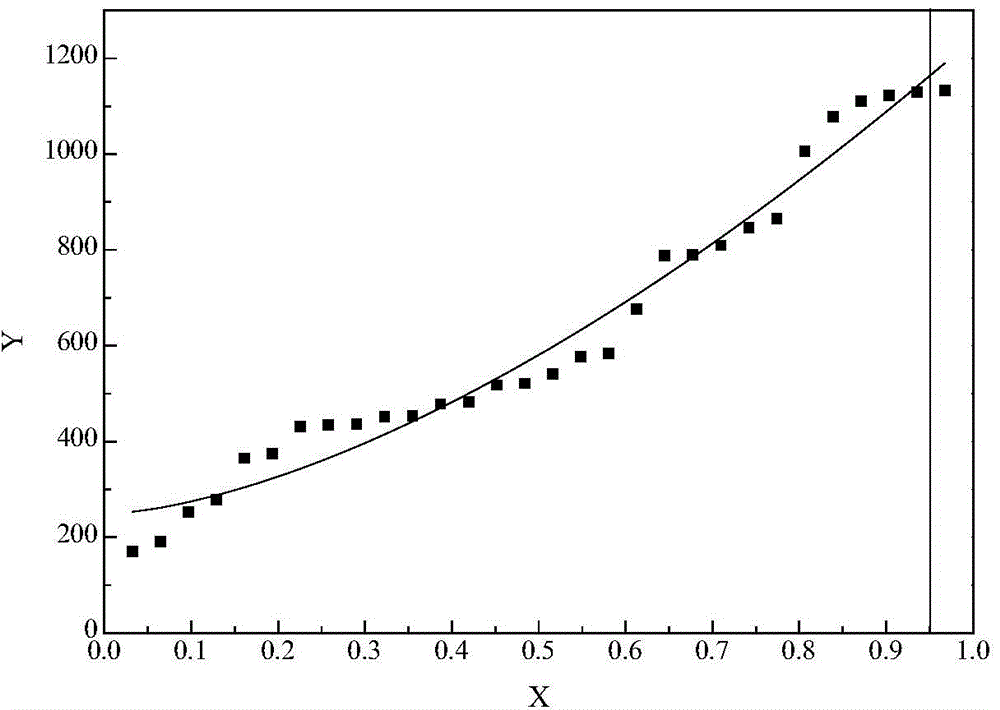

[0027] Embodiment one: figure 2 For AgNi electrical contact material Weibull complete data statistics method, get figure 2 Proceed as follows:

[0028] Step 1: The number of static welding force experiments for AgNi electrical contact materials is n=30, and the obtained data are shown in the following table:

[0029] Number of experiments Static welding force (g) 1 584 2 1111 3 865 4 521 5 518 6 1005 7 846 8 253 9 435 10 1077 11 374 12 478 13 790 14 809 15 1133 16 540 17 191 18 453 19 170 20 1122 21 676 22 1129 23 436 24 278 25 482 26 451 27 431 28 365 29 787 30 577

[0030] Step 2: There is no failure data in the experimental data, m=100%;

[0031] Step 3: There is no failure data in the experimental data, adopt the Weibull complete data statistical method, and the independent variable X takes the value of 1 / ...

Embodiment 2

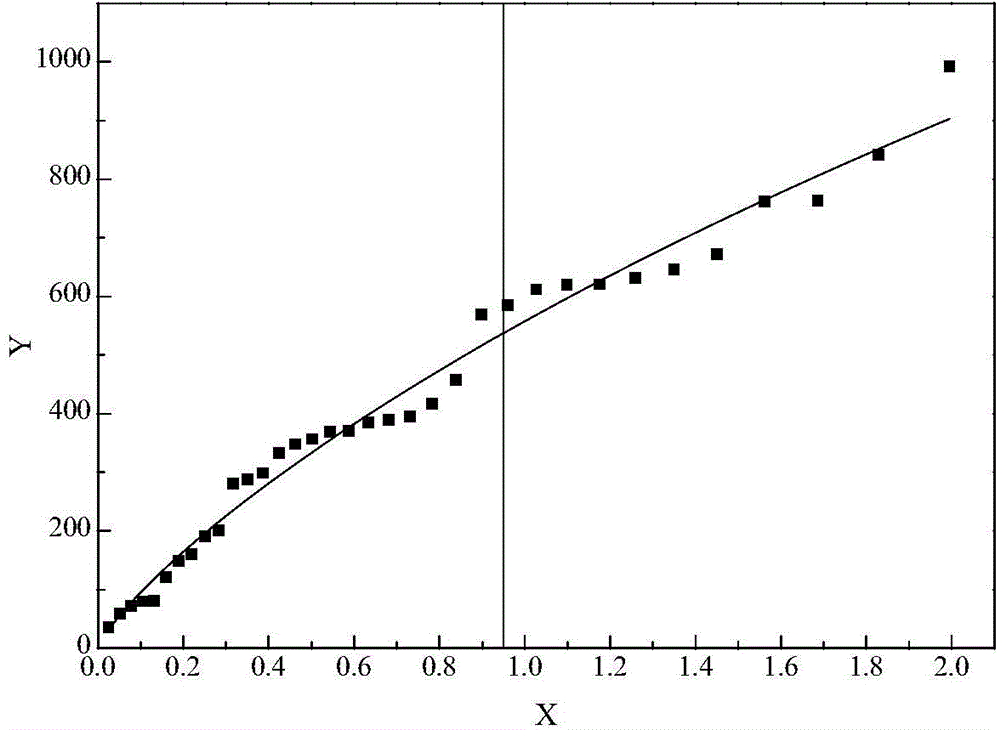

[0035] Embodiment two: image 3 For AgCdO electrical contact material Weibull complete data statistical method, get image 3 Proceed as follows:

[0036] Step 1: The number of static welding force experiments of AgCdO electrical contact material n=40, the obtained data are shown in the following table:

[0037] Number of experiments Static welding force (g) 1 149 2 333 3 288 4 569 5 457 6 81 7 992 8 72 9 842 10 385 11 36 12 80 13 395 14 0 15 763 16 0 17 348 18 369 19 280 20 201 21 589 22 59 23 0 24 0 25 612 26 160 27 672 28 390 29 632 30 417 31 620 32 621 33 762 34 370 35 299 36 357 37 191 38 646 39 0 40 122

[0038] Step 2: There are failure data in the experimental data, m=87.5%;

[0039]Step 3: There are failure data in the experimental data, using the Weibull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com