Determination method of volume expansibility and contractibility of oil well cement solidification material

A technology for solidifying materials and measuring methods, applied in material weighing, analyzing materials, measuring devices, etc., can solve the problems of unstable contact, unclear concept, and undiscovered, to eliminate the influence of measurement accuracy, easy to popularize, instrument simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

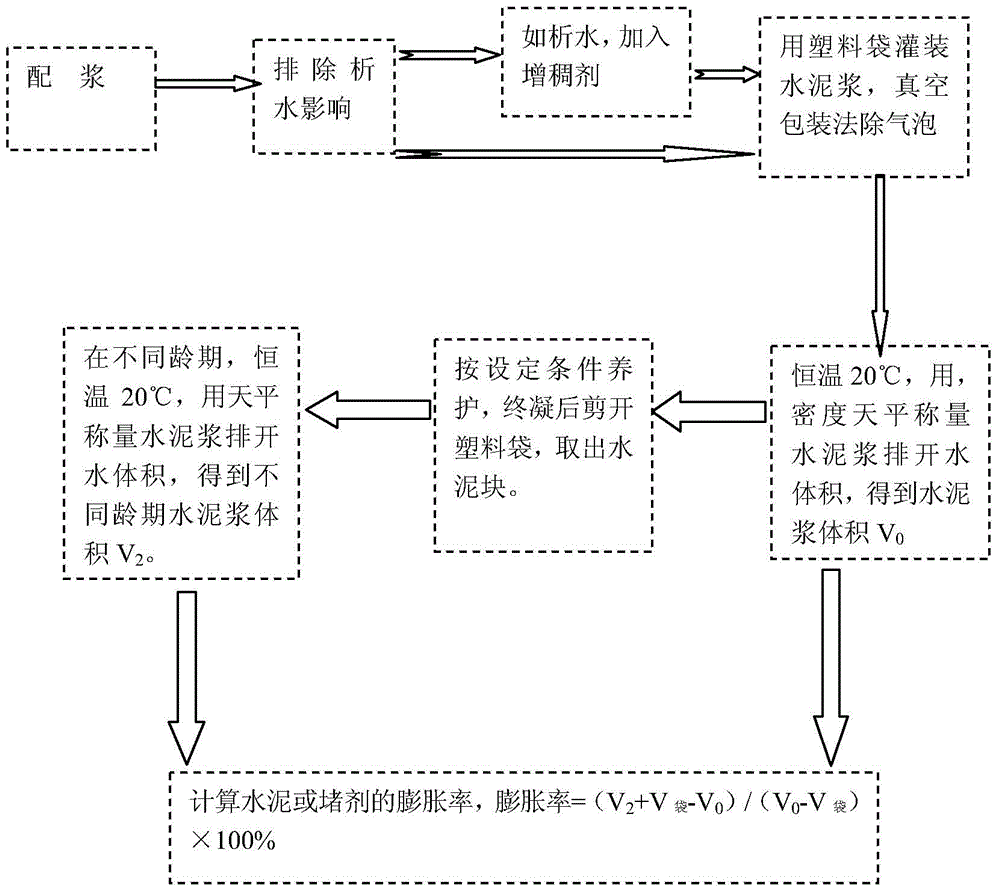

[0050] refer to figure 1 Shown flow process, the method for measuring the volume change of cement and plugging agent of the present invention operates according to the following steps:

[0051] ① Prepare cement slurry or plugging agent;

[0052] ②Let the cement slurry or plugging agent stand for 2 hours, and it is required not to separate water. If water separates, add 0.5% stabilizer to the original cement slurry and stir evenly; it must be ensured that no water separates, otherwise the precipitated water in step ⑥ will overflow and affect the measurement accuracy.

[0053] ③Pour cement slurry or blocking agent into plastic bags or rubber bags, and use a vacuum packaging machine for vacuum packaging with a vacuum degree of 0.013MPa to fully remove the air bubbles in the bags. The amount of cement slurry or plugging to be poured is adjusted according to the range of the density balance, preferably 80% of the range of the balance (for example, the range of the density balance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com