Electrochromic device for screening inverse opal photonic crystal structure with high flux

An electrochromic device and anti-opal technology, applied in instruments, optics, nonlinear optics, etc., can solve the problems of complex operation, low screening efficiency, high manpower and financial costs, etc., to improve screening efficiency, speed up research and development, and save cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A method for preparing an electrochromic device for high-throughput screening of an inverse opal photonic crystal structure, comprising the following steps:

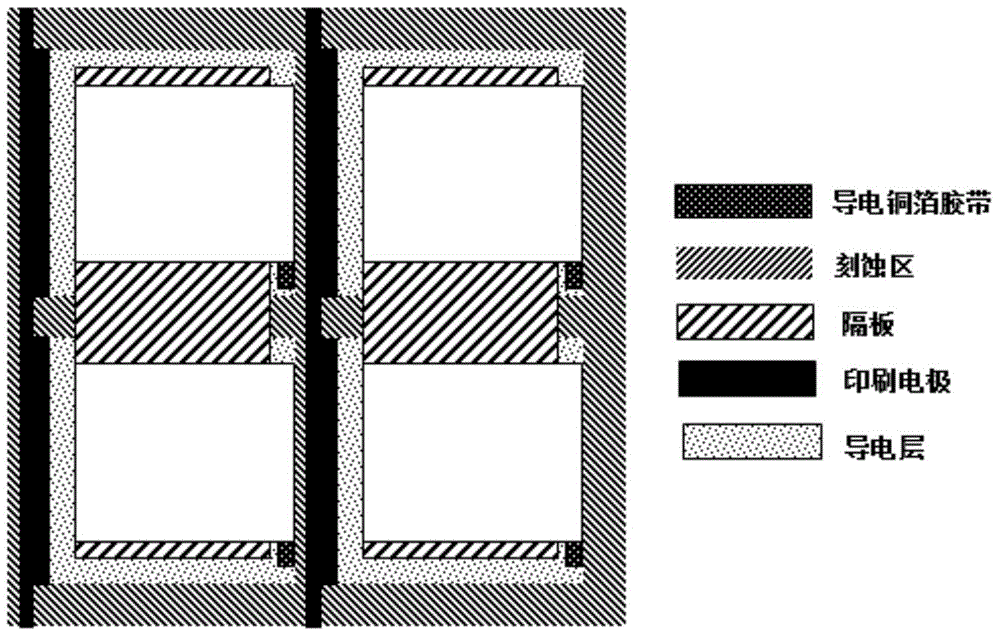

[0047] Step 1: Etch on the transparent conductive substrate to form a conductive layer arranged in an n×n matrix. Each etched strip has the same width and is insulated. After the etching is completed, clean it with sodium hydroxide, deionized water and absolute ethanol respectively. 5-10 times, then dry in an oven at 50-150°C;

[0048] Step 2: Use a screen printing machine to brush conductive paste on one row or one column of etching strips of the transparent conductive substrate obtained after the treatment in step 1, and sinter and solidify it as a printed electrode, and the printed electrode is connected to each corresponding row or column. A conductive layer is connected, the number of the printed electrodes is n, and the thickness of the printed electrodes is equal to the etching depth in step 1;

[0049] St...

Embodiment

[0058] A high-throughput screening method for electrochromic devices with an inverse opal photonic crystal structure includes the following steps:

[0059] Step 1: Use hydrochloric acid and zinc powder to etch on the ITO transparent conductive substrate to form a conductive layer arranged in a 2×2 matrix. Each etching strip has a width of 4mm and is insulated. Wash with deionized water and absolute ethanol for 5 times, and then dry in an oven at 80°C;

[0060] Step 2: Use a screen printing machine to brush conductive silver paste on a row of etching strips of the transparent conductive substrate obtained after step 1, and sinter and solidify it as a printing electrode, and the printing electrode is connected to each conductive layer corresponding to a row , the number of the printed electrodes is 2, and the thickness of the printed electrodes is equal to the etching depth in step 1;

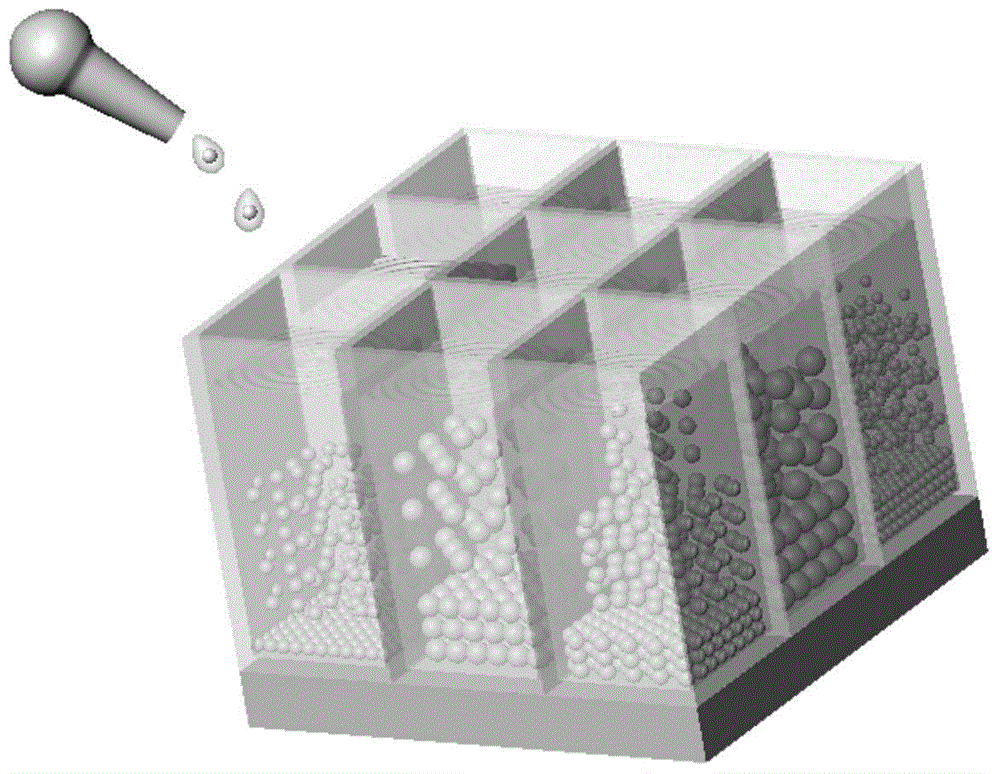

[0061] Step 3: Place a polytetrafluoroethylene spacer on the transparent conductive substrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com