Deeply curable UV-to-black adhesive

A deep curing and adhesive technology, applied in the direction of adhesives, adhesive additives, adhesive types, etc., can solve the problems that affect the strength and curing effect of the glue body, the proportion of dyes should not be too much, and the color will fade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

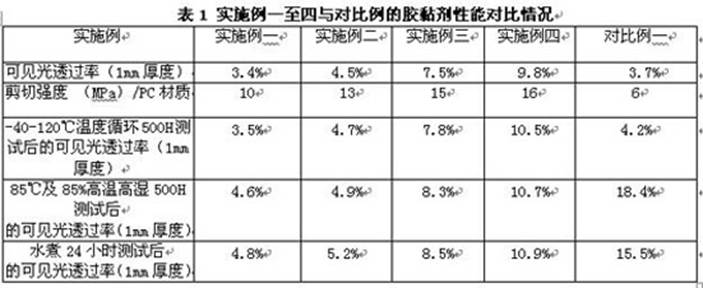

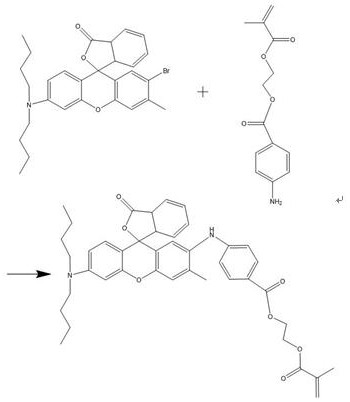

[0030] Step 1 Preparation of fluoran-based acrylate monomer

[0031] 2-Bromo-3-methyl-6-N,N-bisbutylamino-fluoran (CAS: 117342-26-4) and 2-(methacrylate)ethyl 4-aminobenzoic acid (CAS: 130291 -82-6) Add to solvent A, then add catalyst A, the reaction temperature rises to 80°C, and the reaction time is 2 hours to obtain fluoran acrylate monomers, which are photochromic fluoran containing double bonds Acrylate monomer, its molecular structure formula is as follows:

[0032]

[0033] Wherein 2-bromo-3-methyl-6-N, N-bisbutylamino-fluorane, 2-(methacrylic acid) ethyl ester 4-aminobenzoic acid, the mass ratio of solvent A and catalyst A is: 1: 1:10:0.01; the solvent A is formamide; the catalyst A is triethylamine.

[0034] Step 2 Preparation of deep-curable UV blackening adhesive

[0035] Mix and stir the fluoran acrylate monomer, photoacid generator, amine compound, acrylic resin, diluent, crosslinking agent, photoinitiator, silane coupling agent and filler synthesized in ste...

Embodiment 2

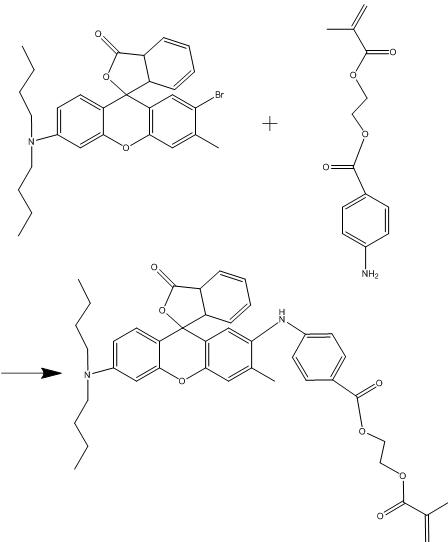

[0038] Step 1 Preparation of fluoran-based acrylate monomer

[0039]2-Bromo-3-methyl-6-N,N-bisbutylamino-fluoran (CAS: 117342-26-4) and 2-(methacrylate)ethyl 4-aminobenzoic acid (CAS: 130291 -82-6) Add to solvent A, then add catalyst A, the reaction temperature rises to 100°C, and the reaction time is 6 hours to obtain fluoran acrylate monomers, which are photochromic fluoran containing double bonds Acrylate monomer; its molecular formula is as follows:

[0040]

[0041] Wherein 2-bromo-3-methyl-6-N, N-bisbutylamino-fluorane, 2-(methacrylic acid) ethyl ester 4-aminobenzoic acid, the mass ratio of solvent A and catalyst A is: 1: 3:30:0.03; the solvent A is: nitrogen methyl pyrrolidone; the catalyst A is sodium hydroxide.

[0042] Step 2 Preparation of deep-curable UV blackening adhesive

[0043] Stir the fluoran acrylate monomer, photoacid generator, amine compound, acrylic resin, diluent, crosslinking agent, photoinitiator, silane coupling agent and filler synthesized in...

Embodiment 3

[0046] Step 1 Preparation of fluoran-based acrylate monomer

[0047] 2-Bromo-3-methyl-6-N,N-bisbutylamino-fluoran (CAS: 117342-26-4) and 2-(methacrylate)ethyl 4-aminobenzoic acid (CAS: 130291 -82-6) Add to solvent A, then add catalyst A, the reaction temperature rises to 80°C, and the reaction time is 3 hours, and the fluoran acrylate monomer, which is the color-changing fluoran acrylate containing double bonds, can be obtained Monomer, its molecular formula is as follows:

[0048]

[0049] Wherein 2-bromo-3-methyl-6-N, N-bisbutylamino-fluorane, 2-(methacrylic acid) ethyl ester 4-aminobenzoic acid, the mass ratio of solvent A and catalyst A is: 1: 2:20:0.02; the solvent A is dimethyl sulfoxide; the catalyst A is potassium hydroxide.

[0050] Step 2 Preparation of deep-curable UV blackening adhesive

[0051] Stir the fluoran acrylate monomer, photoacid generator, amine compound, acrylic resin, diluent, crosslinking agent, photoinitiator, silane coupling agent and filler s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com