Control system for carbon fiber winding machine cutter

A cutting device and control system technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of no cutting timing control system, inconsistent fiber length of each roll, cost increase, etc., to reduce costs, ensure consistency, avoid wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the technical content of the present invention, the specific embodiments are specifically cited and described as follows in conjunction with the accompanying drawings:

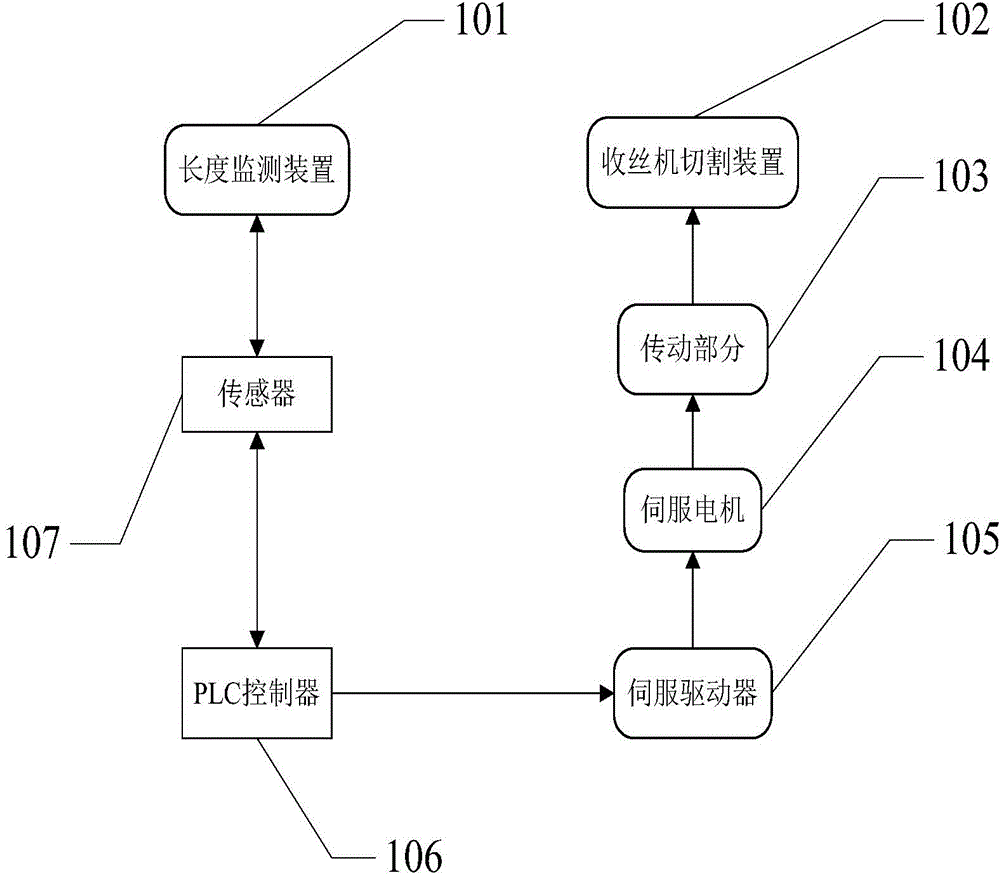

[0023] Such as figure 2 As shown, the control system of a cutting device of a carbon fiber winding machine proposed by the present invention adopts the following technical scheme, and the system includes:

[0024] The PLC controller 106 is used to send motion instructions to the servo driver 105;

[0025] The servo driver 105 is used to drive the servo motor 104 after receiving the command of the PLC controller 106;

[0026] The servo motor 104 completes the control of the cutting action of the wire receiving machine through the transmission part 103;

[0027] The transmission part 103 is used to transmit power to the cutting device 102 of the wire receiving machine;

[0028] The cutting device 102 of the wire receiving machine completes the cutting action on time accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com