A liquid crystal array type infrared touch screen

An infrared touch screen, liquid crystal array technology, applied in optics, instruments, electrical digital data processing, etc., can solve problems such as overall sensitivity decline and light intensity decline, and achieve touch screen sensitivity assurance, high arrangement density, and improved touch resolution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

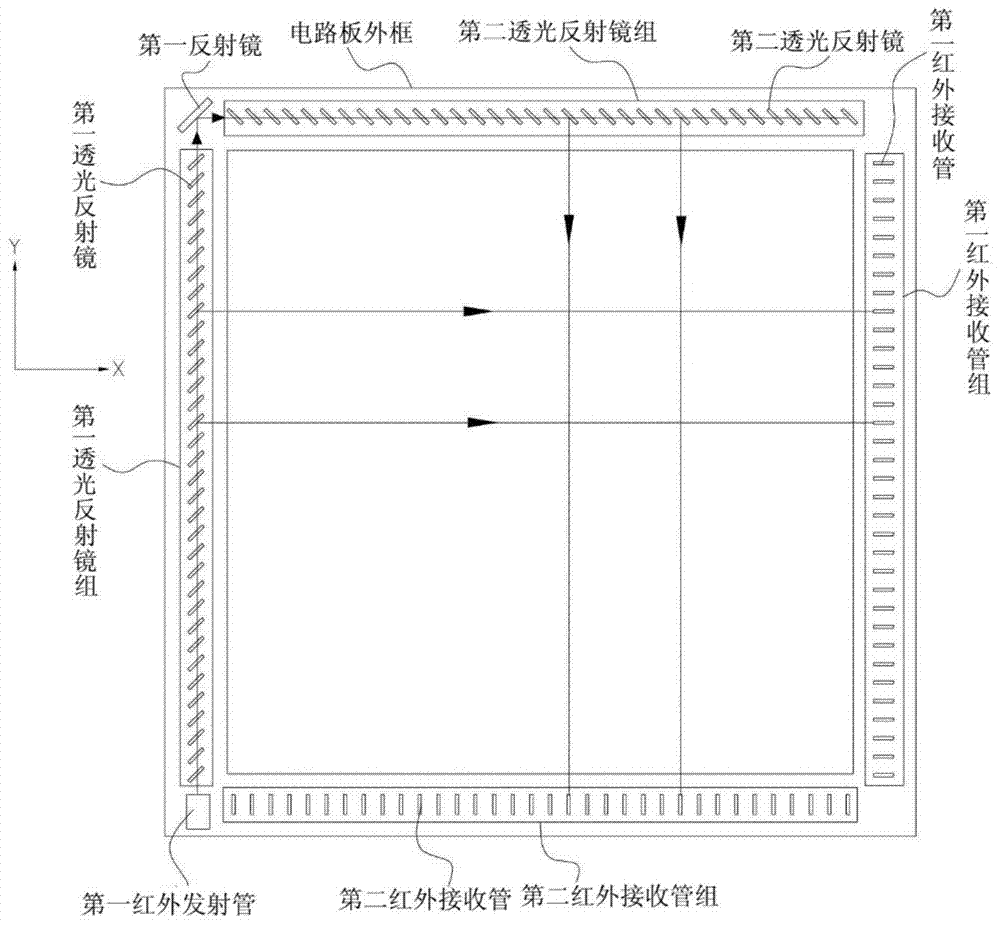

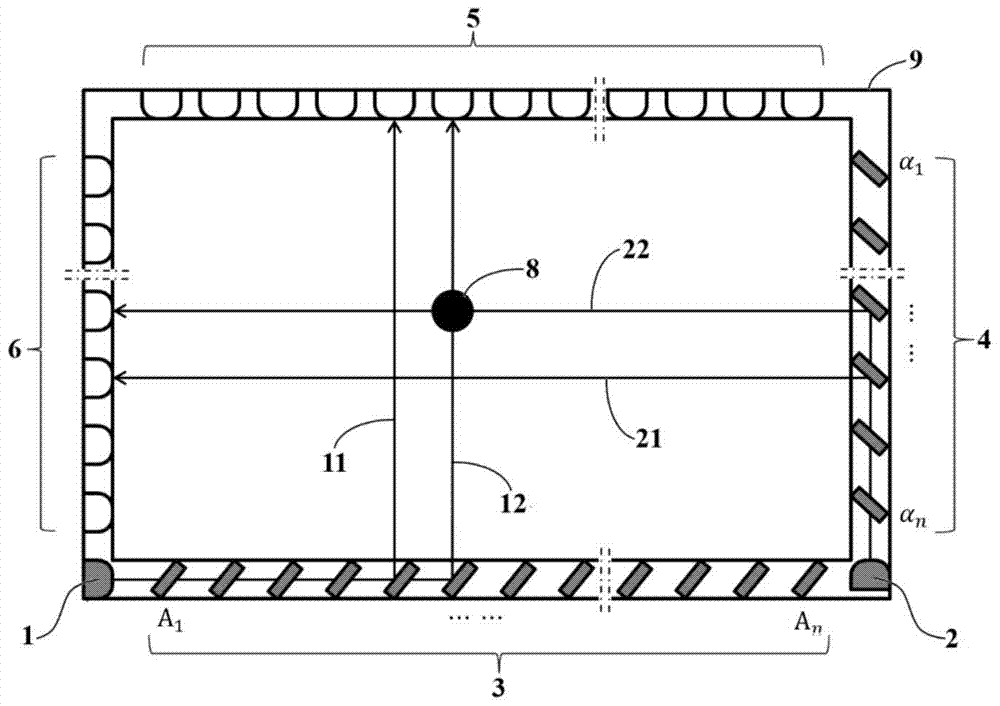

[0033] This embodiment is the implementation of the first technical solution of the present invention. Such as image 3 As shown, a row of cholesteric liquid crystal arrays 3 and 4 are respectively arranged on one long side and a short side of the touch screen 9, and a row of infrared liquid crystal arrays are arranged on the other long side and short side of the touch screen 9. Detector arrays 5 and 6, infrared detectors correspond to the cholesteric liquid crystal reflection light path on the opposite side; the pitch of the cholesteric liquid crystals in the cholesteric liquid crystal arrays 3 and 4 is the same, so that all the cholesteric liquid crystals in one array have the same pitch. The helical structure of liquid crystals is the same.

[0034] The working mode of the device described in this embodiment is as follows:

[0035] The scanning voltage control device (not shown in the figure) gives image 3 Cholesteric liquid crystal A in the cholesteric liquid crystal a...

Embodiment 2

[0039] In order to improve the response speed, on the basis of Embodiment 1, infrared emitting tubes 1 are respectively provided at both ends of the long sides. Such as Figure 4 As shown, the cholesteric liquid crystal array 3 is divided into two sections, and the first section includes the cholesteric liquid crystal A 1 to A n , the second segment includes cholesteric liquid crystal B 1 to B n , the light emitted by the infrared emission tube 1 at the left end is emitted by the cholesteric liquid crystal A 1 to A n Reflection, the light emitted by the infrared emission tube 1 at the right end is emitted by the cholesteric liquid crystal B 1 to B n Reflection; in the short side, the light emitted by the infrared emitting tube 2 is controlled by the cholesteric liquid crystal α in the cholesteric liquid crystal array 4 1 to α n reflection. Cholesteric liquid crystal A 1 to A n , B 1 to B n 、α 1 to α n The three-segment array scans at the same time, so the longes...

Embodiment 3

[0041] Such as Figure 5 As shown, on the basis of embodiment 2, an infrared emission tube 1 and reflector 7 are added in the middle of the long side, and the infrared rays emitted vertically by the infrared emission tube 1 are reflected to the long side direction through the reflector 7; Infrared emission tubes 2 are arranged at both ends of the side, the cholesteric liquid crystal array 3 is divided into three sections, the cholesteric liquid crystal array 4 is divided into two sections, and the cholesteric liquid crystal A 1 to A n Reflecting the light from infrared emission tube 1 at the left end, cholesteric liquid crystal B 1 to B n Reflecting the light from the infrared emission tube 1 in the middle of the long side, cholesteric liquid crystal C 1 to C n Reflecting the light from infrared emission tube 1 at the right end, cholesteric liquid crystal α 1 to α n Reflect the light from the upper infrared emission tube 2, cholesteric liquid crystal β 1 to beta n Refl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com