Part remanufacturing method based on reverse engineering

A reverse engineering and component technology, applied in image analysis, instrumentation, calculation, etc., can solve the problems of difficult standardization and quantification of repair methods and parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

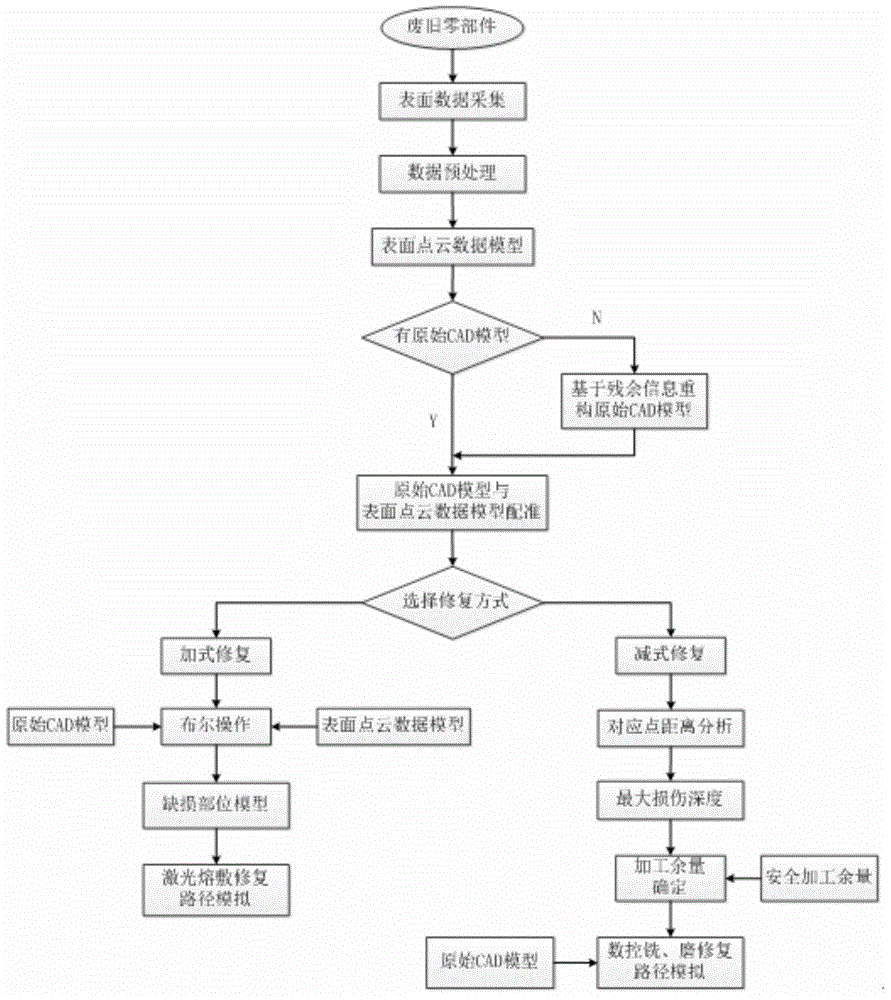

[0028] A method for remanufacturing components based on reverse engineering, comprising the following steps:

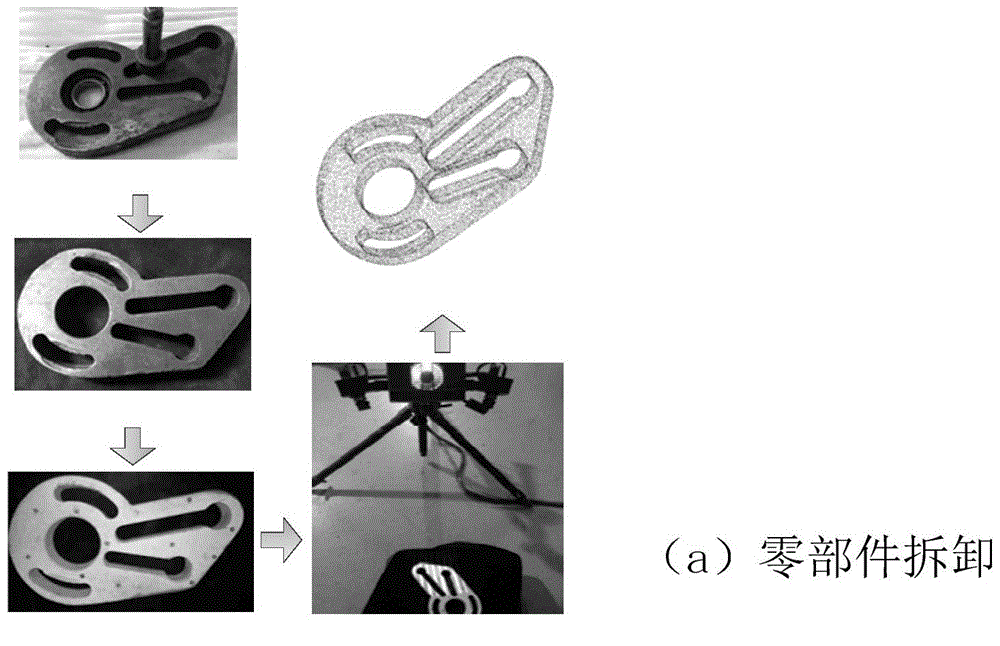

[0029] 1) Obtain the surface point cloud data model of waste parts. see figure 2 , in the figure, the ATOS optical three-dimensional scanner is used to collect data on waste parts. This equipment has strong mobility and fast data collection speed, and can obtain surface point cloud data of various parts. In the embodiment, the surface of the waste parts to be tested is sprayed with a white developer before collection to enhance the effect. The collected results are as image 3 .

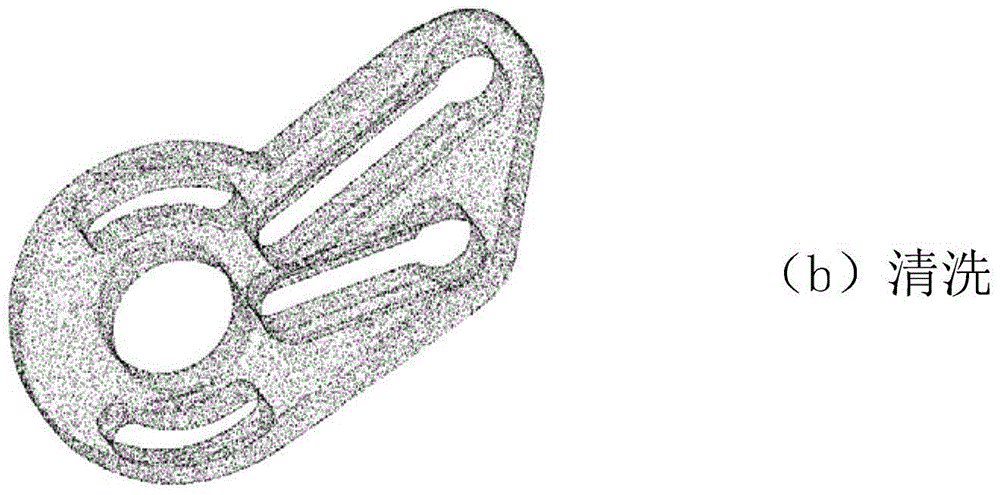

[0030] In an embodiment, preferably, for image 3 The shown acquisitions were pre-processed (filtering, noise removal, data reduction, etc.) to obtain results such as Figure 4 The surface point cloud data model of the scrap parts shown can be used as the processing object in the next step.

[0031] 2) Obtain the original CAD model (unworn) of the scrap parts. In this embodiment, the...

Embodiment 2

[0037] During the repair process of waste parts, the original CAD file of the part may be lost. At this time, the original CAD model needs to be reconstructed according to the residual information in the collected surface point cloud data. Different from traditional reverse modeling, when reconstructing the original CAD model of waste parts, because the collected point cloud data contains the damage area of the part, this part of the point cloud data is not continuous with the point cloud of other intact areas, and cannot Reflect the original surface topography of the parts, so the point cloud data of the damaged area should be avoided during reverse reconstruction.

[0038] The main steps of this embodiment are the same as those of Embodiment 1, except that the original CAD model described in step 2) needs to be obtained through the following steps.

[0039] In the embodiment, by calculating the Gaussian curvature of each point in the point cloud data, the points where the ...

Embodiment 3

[0054] The main steps of this embodiment are the same as those of Embodiment 1, and further, an improved registration method suitable for step 3) is disclosed.

[0055] It is worth noting that the registration of the surface point cloud data model of waste parts and the original CAD model is the key to obtain the maximum damage depth. The registration between the two models usually requires two steps of pre-registration and fine registration. Pre-registration Accurate is to roughly adjust the two models to the correct position, provide a good initial value for accurate registration, and improve the efficiency of accurate registration. The methods of pre-registration mainly include principal component analysis, moment axis method, three-point alignment method, etc. . Accurate registration is to further correct the positions of the two models on the basis of pre-registration to minimize the difference between the two models. Among the precise registration algorithms, the Iterat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com