Shot peening strengthening treatment process parameter determination method based on finite element analysis

A processing technology and shot peening technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., to save manpower and material resources and increase practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The method for determining the process parameters of shot peening treatment based on finite element analysis in this embodiment is performed as follows:

[0034] Step 1: Build a finite element model

[0035] Use the material properties of the projectile and the material to be sprayed to establish a local finite element model for the projectile and the material to be sprayed, simulate the entire shot peening process with the local finite element model, and use non-reflective boundary conditions, symmetry planes and fixed constraints to reduce the effect of the boundary on the simulation The material properties of the projectile and the sprayed material are characterized by material parameters, which refer to the Young’s modulus, Poisson’s ratio, density, yield strength and tangent modulus of the projectile and the sprayed material.

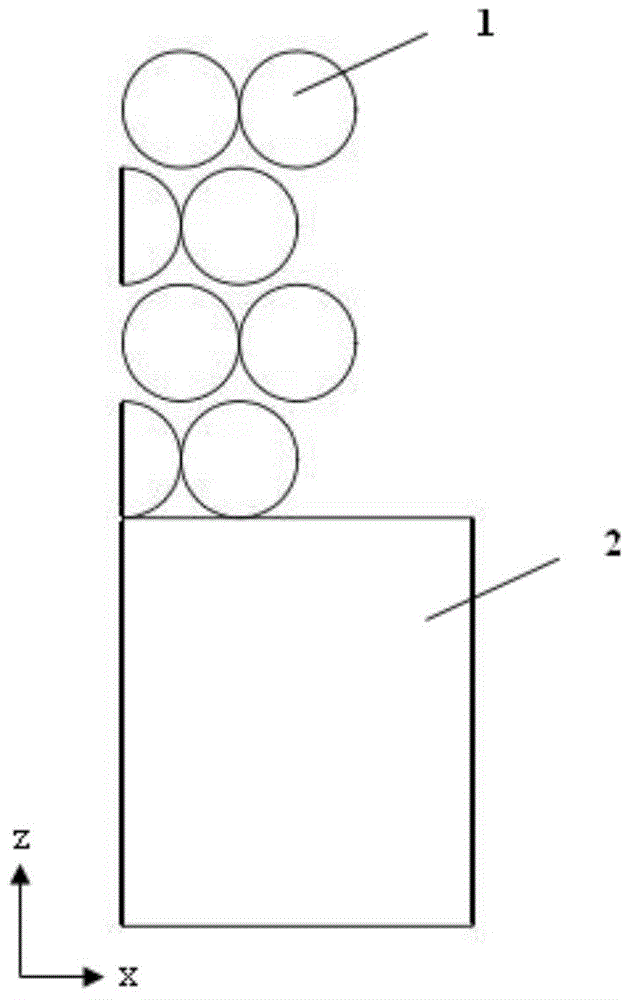

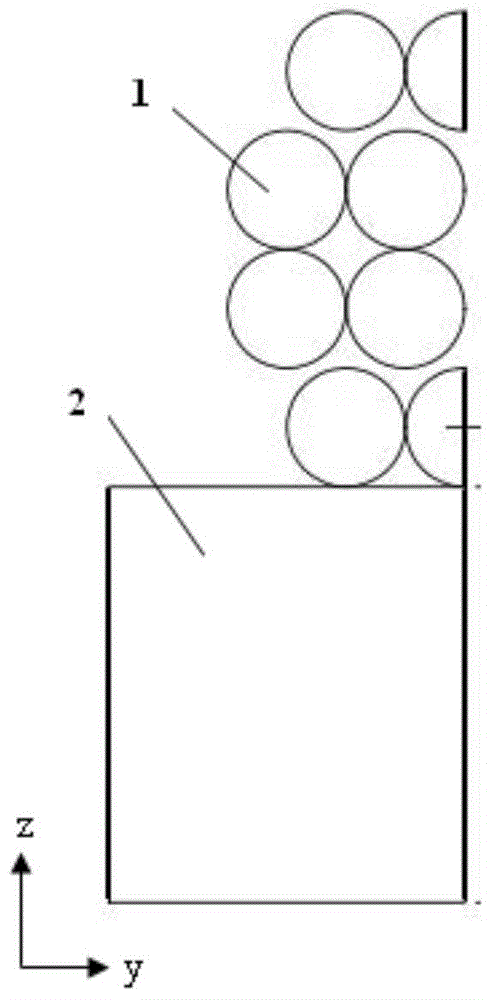

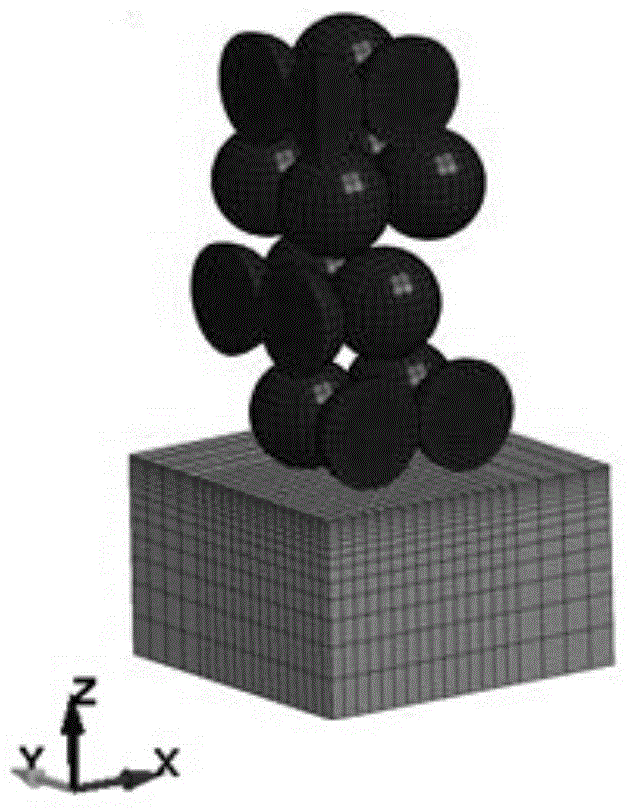

[0036] Such as Figure 1a and Figure 1b As shown, the local finite element model includes four layers of projectiles 1 with a radius of R, and a r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com