A method for remote monitoring of process and intelligent identification of mold opening and locking states

A remote monitoring and intelligent identification technology, which is applied in the field of remote monitoring process and intelligent identification of mold opening and locking status, can solve problems such as inability to achieve real-time monitoring and timely troubleshooting, crushed molds, safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

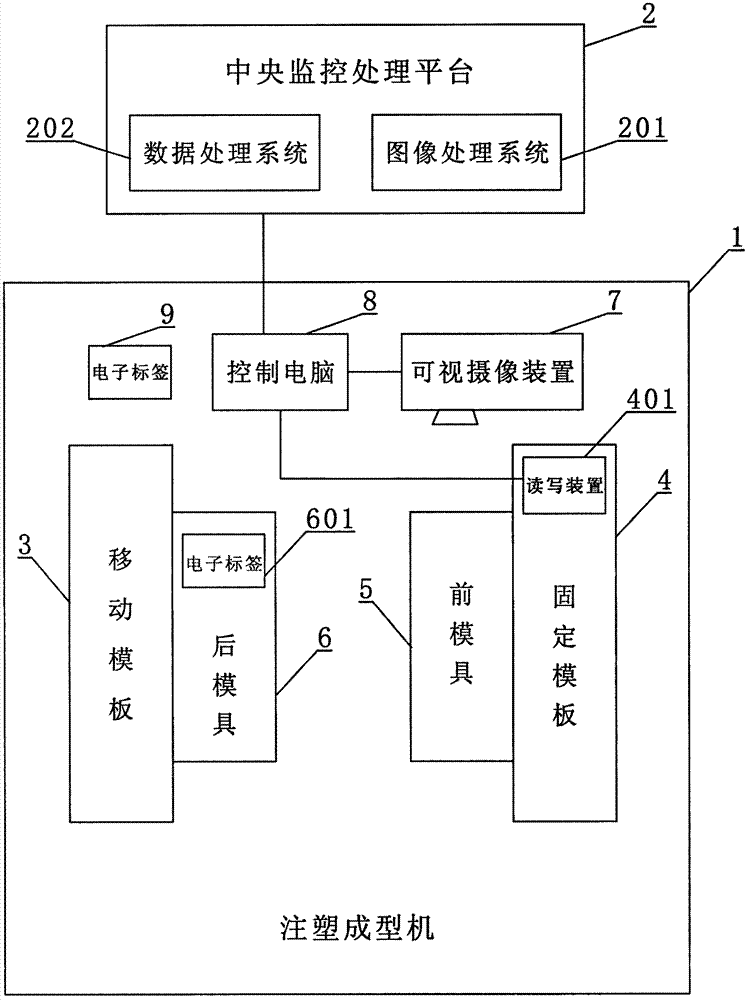

[0039] A method that can remotely monitor the process and intelligently identify the mold opening and locking status, and is mainly used for the control of the working status of the injection molding machine. Its characteristics are:

[0040] The method comprises the steps of:

[0041] (1) Device electronic label

[0042] Set an electronic label 601 on the appropriate part of the mold, and the electronic label 601 stores data information of various production process parameters of the mold;

[0043] (2) Install the reading and writing device

[0044] Install a read-write device 401 on the template of the injection molding machine 1. When the injection molding machine 1 starts to work, the read-write device 401 scans and reads the data information of the electronic tag 601 on the mold, and transmits the scanned and read data information to The control computer 8 of the injection molding machine 1 stores;

[0045] (3) Transmission and storage of scanned and read data informat...

Embodiment 2

[0062] The difference between Embodiment 2 and Embodiment 1 mainly lies in the setting of the electronic tag 601 and the read-write device 401, so the similar parts are not described in detail here.

[0063] In Embodiment 2, the electronic tag 601 is arranged on the non-cavity area of the front mold 5 on one side of the fixed template 4, and the read-write device 401 is arranged on the movable template 3, so that when the injection molding machine 1 Start work, when the mobile template 3 runs to a certain distance from the fixed template 4, the read-write device 401 installed on the movable template 3 automatically scans and reads the data information in the electronic tag 601 on the front mold 5.

Embodiment 3

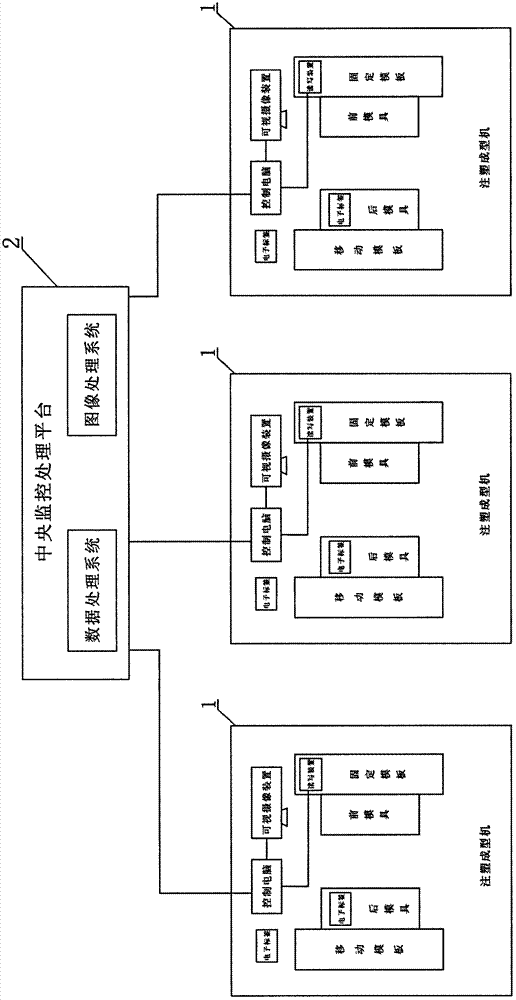

[0065] The main difference between Embodiment 3 and Embodiment 1 lies in the settings of the data processing system 202 and the image processing system 201, so similar parts are not described in detail here.

[0066] In Embodiment 3, the control computer 8 of the injection molding machine 1 adopts a built-in data processing system 202 and an image processing system 201, so that data information such as mold production process parameters and images of mold opening and locking actions do not need to pass through the central monitoring and processing platform 2 Processing, the control computer 8 of the injection molding machine 1 can directly complete the storage and recording of data information such as mold production process parameters, as well as the data processing and comparison of the opening and closing action images.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com