A preparation method and equipment for a coating layer of an electric heating network

A technology of coating layer and electric heating network, which is applied in the direction of coating, liquid coating device on the surface, pretreatment surface, etc., can solve the problems of complex coating layer of electric heating network, cumbersome production process, poor product quality control, etc. , to achieve the effect of easy quality control, long service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

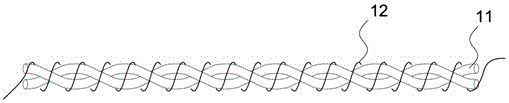

[0037] A device for preparing a coating layer of an electric heating network, comprising a dip coating area, a hot air drying area, and a heat curing area arranged in sequence. When in use, inject the slurry of the coating layer material into the dip coating area, and then send the base material to be coated to the dip coating area to be immersed in the slurry of the coating layer material, so that the slurry of the coating layer material wets the substrate The surface of the material, and then immediately sent to the hot air drying area, under the action of hot air, the coating material slurry coated on the surface of the base material is gradually dried, and then sent to the heat curing area, under the action of hot air at a higher temperature to achieve Thermal curing of coating layers. The equipment adopts simple structure and convenient operation, and the prepared coating layer has uniform structure and stable performance.

[0038]As an option, in the above-mentioned equ...

Embodiment 2

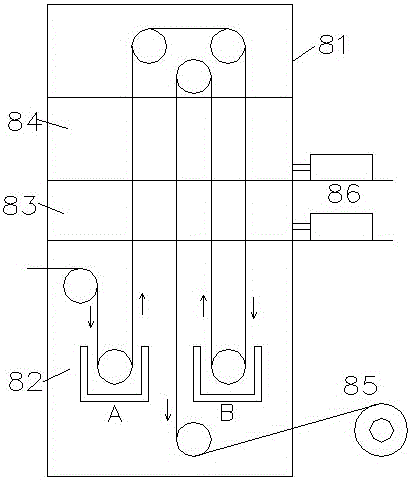

[0050] like figure 1 As shown, a kind of equipment for preparing the coating layer of the electric heating network, the whole equipment is in the shape of a tower, including the tower body and the dip coating area, the hot air drying area and the heat curing area distributed in the tower body from bottom to top in sequence, the hot air The drying area and the heat curing area are respectively connected with the high temperature furnace and the fan through the air supply pipe, and the high temperature air generated in the high temperature furnace is sent to the hot air drying area and the heat curing area respectively through the fan, and the hot air drying area and the heat curing area After the temperature is lowered, the air is recycled or emptied. There are multiple guide rollers in the tower body, and a traction mechanism is provided outside the tower body. The traction mechanism is used to pull the product to drive the base material to be coated in the equipment The dippi...

Embodiment 3

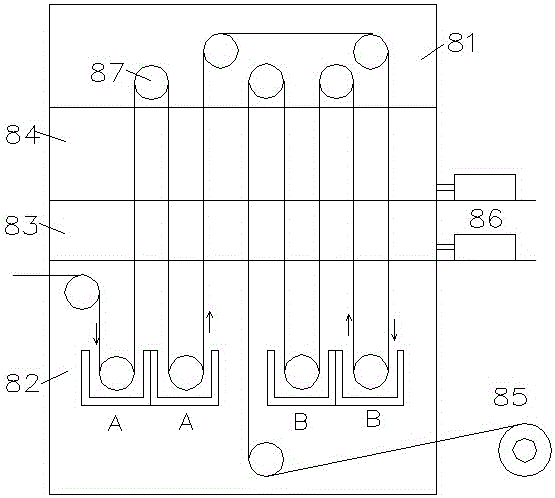

[0056] A kind of equipment for preparing the coating layer of electric heating network, the difference between the equipment and the equipment described in Example 2 is only that: the dip coating area in the tower body includes two first dip coating tanks and two a second dipping tank. When in use, the substrate first enters the first first dip-coating tank for dip-coating, then passes through the hot-air drying zone and heat-curing zone upwards for drying and thermal curing, and then enters the second first dip-coating tank downwards and then goes up sequentially. Pass through the hot air drying area and heat curing area for drying and heat curing, then go down to the first and second dip coating tanks, then go up and pass through the hot air drying area and heat curing area in turn for drying and heat curing, and then go down to the second Two dip coating tanks, and then pass through the hot air drying zone and heat curing zone upwards for drying and thermal curing (this pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com