Adjusting mechanism of scraper for lcd production

A technology for adjusting mechanisms and scrapers, applied to the cleaning method using tools, cleaning methods using gas flow, cleaning methods and appliances, etc., can solve the problem of affecting the quality of the placement process, the platform is on the same horizontal plane, and the glass substrate cannot be obtained. Adequate and thorough cleaning etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

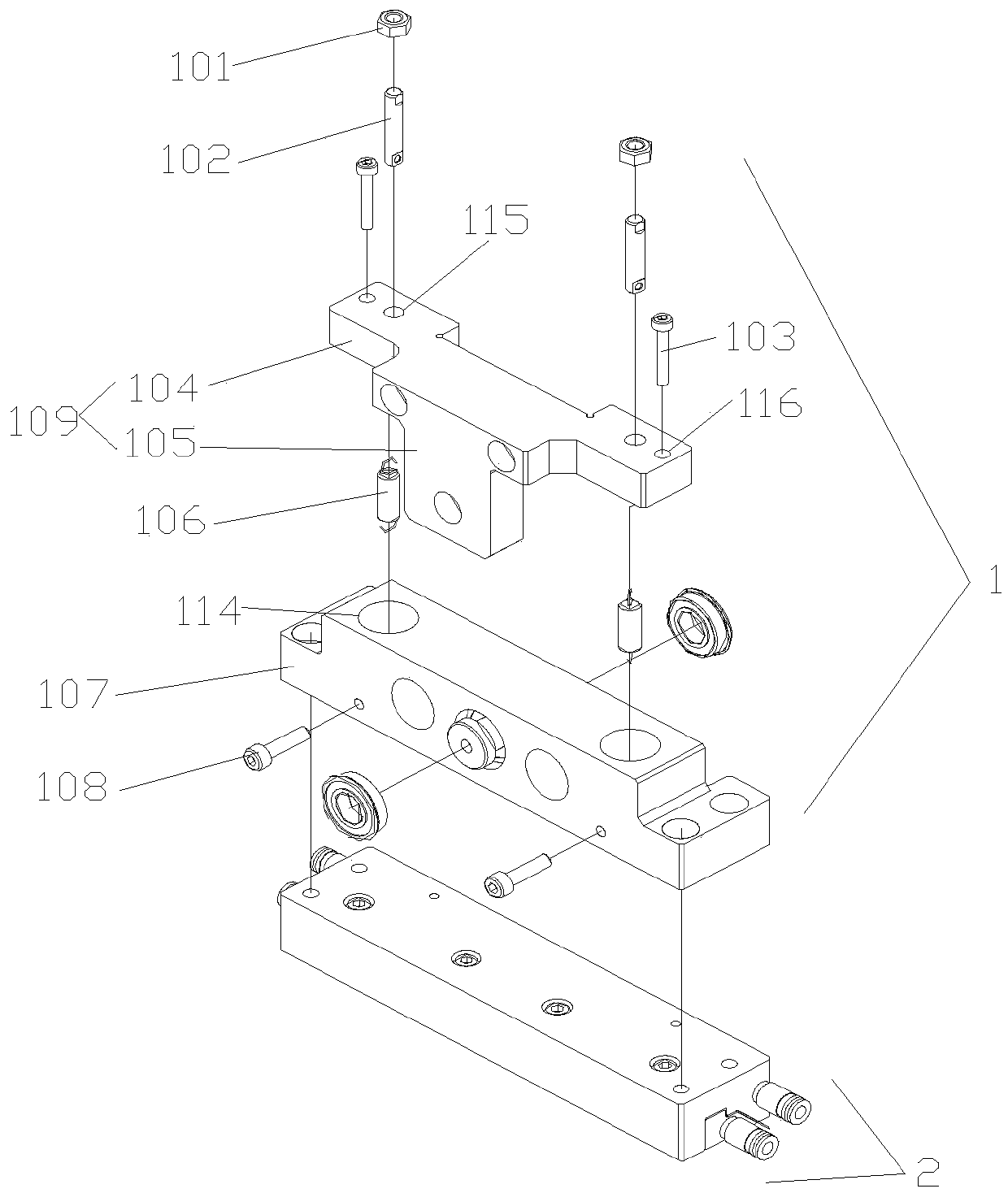

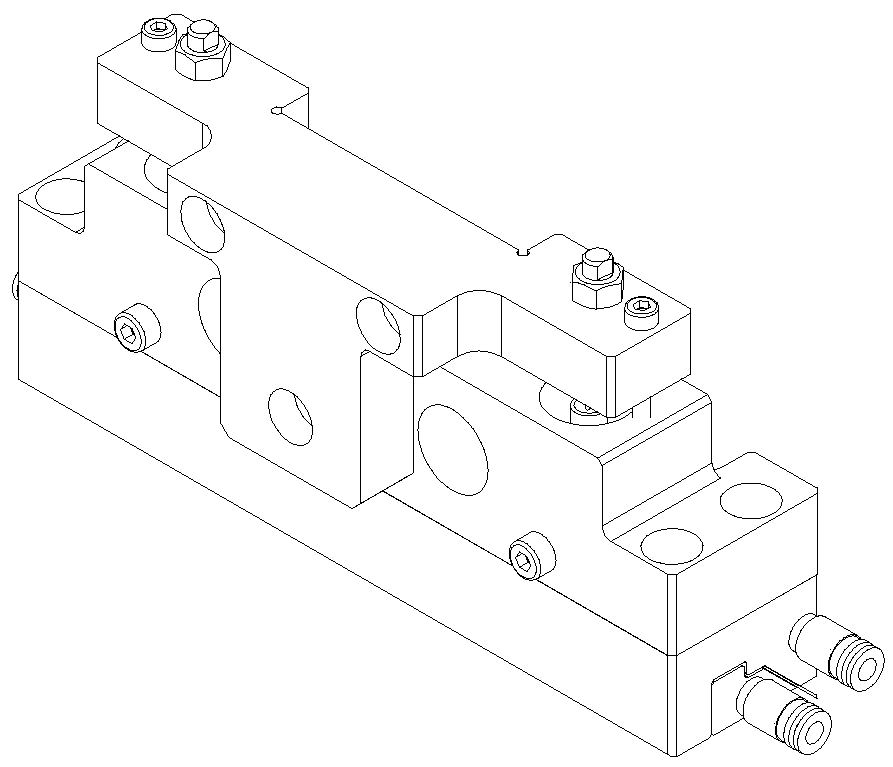

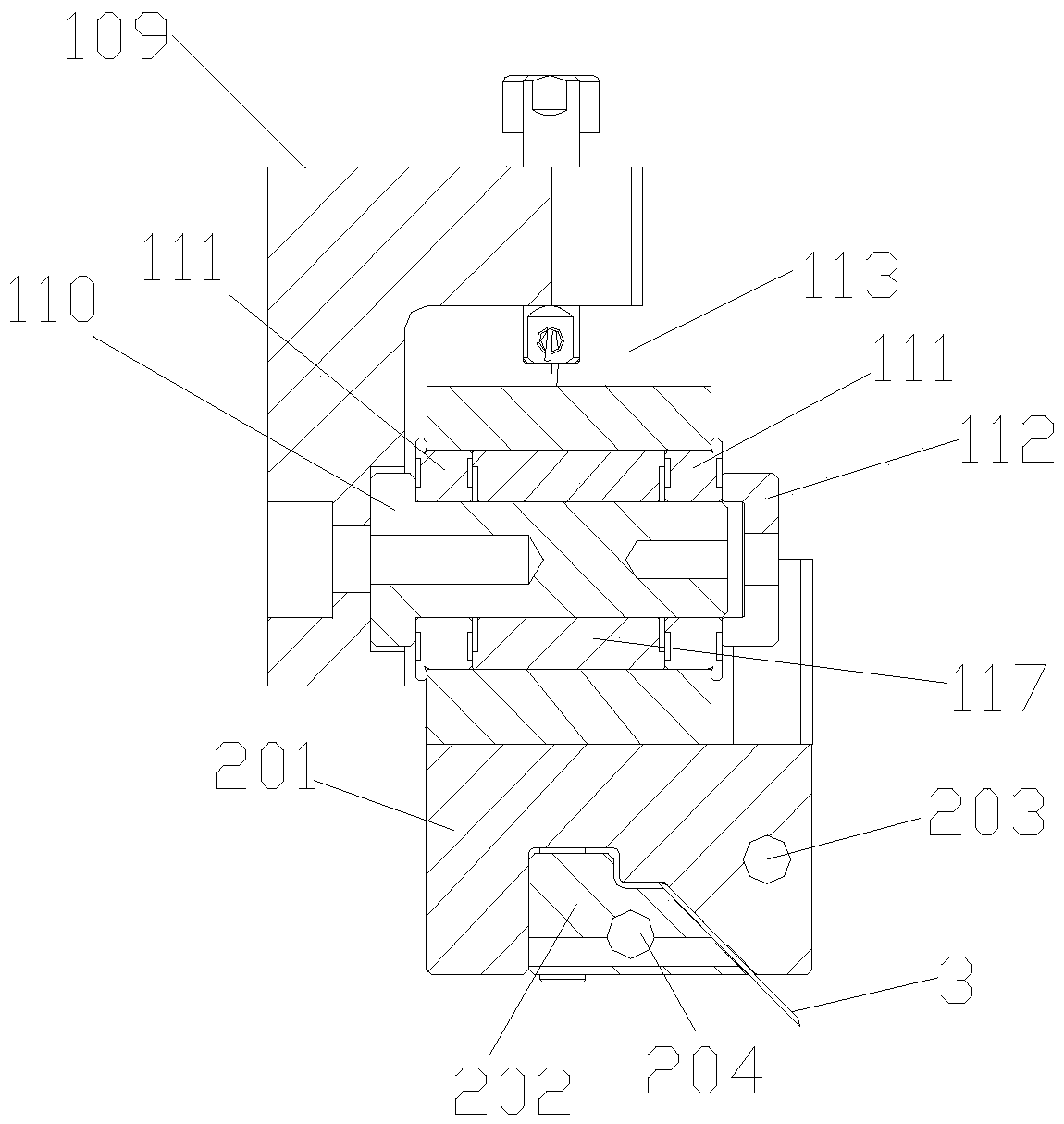

[0022] The adjustment mechanism of the scraper for LCD production of the present invention includes a press head assembly 2 and a rotary drive assembly 1. When there is a certain angle between the press head assembly 2 and the plane to be scraped, the press head assembly 2 passes through the rotation drive assembly. 1 Rotate to be parallel to the plane to be scraped.

[0023] The above-mentioned rotary driving assembly 1 may include a rotating mechanism for controlling the rotation of the press head assembly 2, and also include a detection mechanism for detecting whether the blade is parallel to the surface of the glass substrate. Such a detection mechanism may be a pressure sensor. When in contact, when the pressure difference at both ends of the blade is greater than the set value, it means that the blade needs to be adjusted in angle. Anoth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com