Device for preparing spherical solid-core microchannel plate

A microchannel plate and preparation device technology, which is applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve problems such as different radii of curvature, folds on the edges of annular planes, and gas that cannot be excluded, so as to avoid Oxidation, avoiding the effect of edge wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

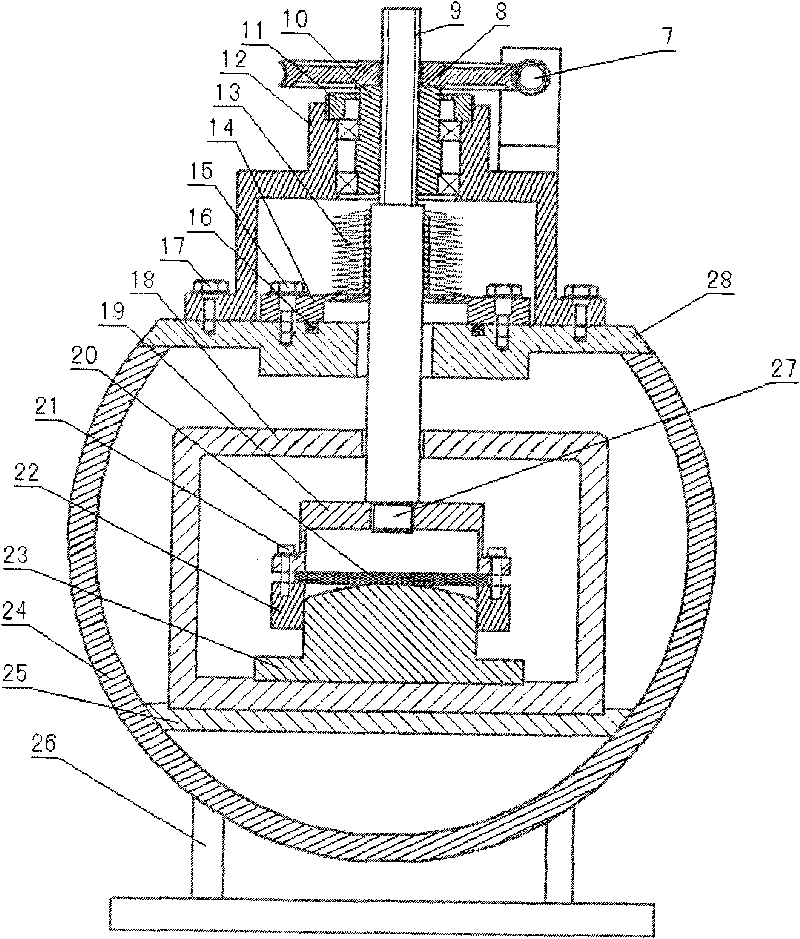

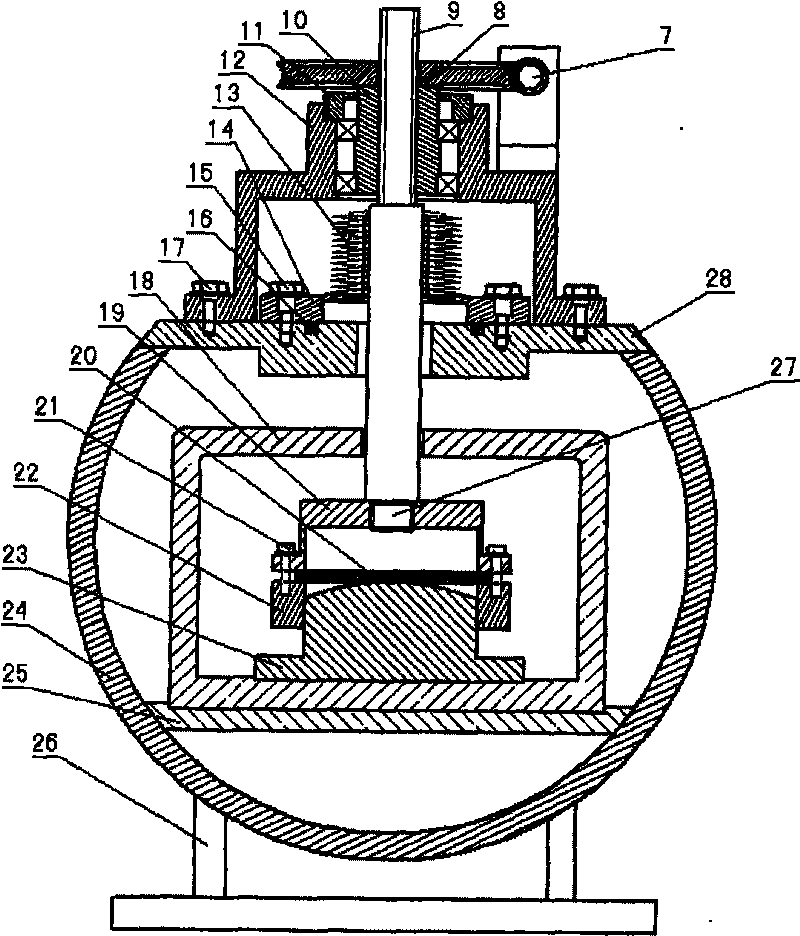

[0013] The invention according to figure 2 The structure shown is implemented, wherein the worm 7 is made of stainless steel, the worm wheel 8 is made of red copper, and the transmission shaft 9 is also made of stainless steel. The part of the screw connection between the transmission shaft 9 and the transmission block 10 is processed with fine threads with a spacing of about 0.5 mm. The transmission shaft The diameter of 9 is 10-30mm, the length of the fine thread part is about tens to more than one hundred mm, and the shaft diameter of the transmission shaft 9 inside the vacuum chamber 24 is several mm larger than the shaft processed with the fine thread; the briquetting block 11 and The supporting frame 12 of the transmission mechanism is made of stainless steel, and the bellows 13 is a hydraulic stainless steel bellows, welded on the transmission shaft 9, with a diameter of 40-80mm, which can realize a downward movement distance of tens to more than one hundred mm; the bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com