Anti-scratch device for bottom of horizontal looper in high-speed wire rolling

A horizontal looper, high-speed wire technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problem of difficult to find seams, folding, wire drawing, red steel is easy to cause scratches, and it is easy to scratch with the bottom plate. and other problems, to achieve the effect of low cost, simple structure and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

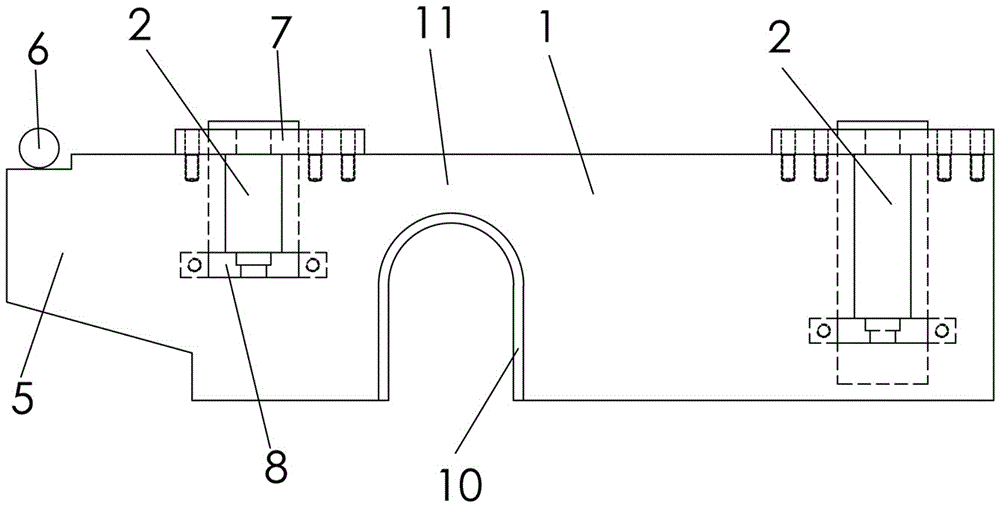

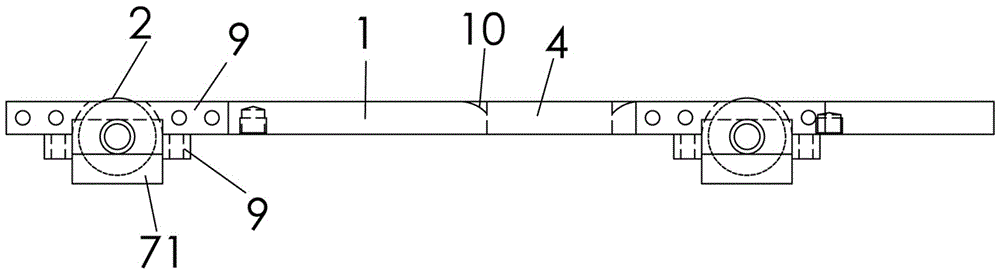

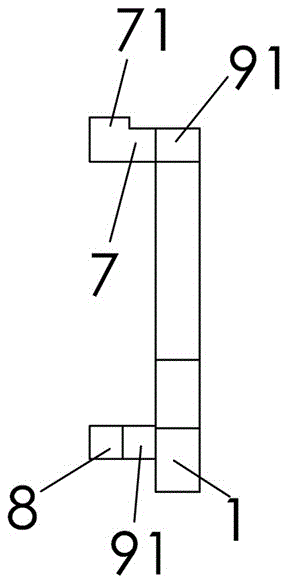

[0042] An anti-scratch device for the bottom of a horizontal looper for high-speed wire rolling, comprising a supporting and guiding base plate 1 horizontally arranged in the looper along the wire traveling direction, and the supporting and guiding base plate is located at the front entrance and the rear end of the horizontal loop Horizontal guide roller 2 is arranged horizontally, the axial direction of the horizontal guide roller is perpendicular to the length direction of the supporting and guiding bottom plate, the horizontal guide roller is embedded in the supporting and guiding bottom plate and the top of the roller surface exceeds the supporting and guiding bottom plate, and the supporting and guiding bottom plate is set There are guide roller grooves 3 for installing horizontal guide rollers, and there are offset push rod grooves 4 for detection on the support guide base plate. The offset push rod grooves have arc-shaped groove bottoms and are open on one side of the sup...

Embodiment 2

[0057] The difference from the above-mentioned embodiment lies in that a horizontal guide roller 2 is arranged horizontally at the entrance of the front end of the horizontal looper on the supporting and guiding base plate.

Embodiment 3

[0059] The difference from the above-mentioned embodiment is that a horizontal guide roller 2 is arranged horizontally at the rear end exit of the horizontal looper on the supporting and guiding base plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com