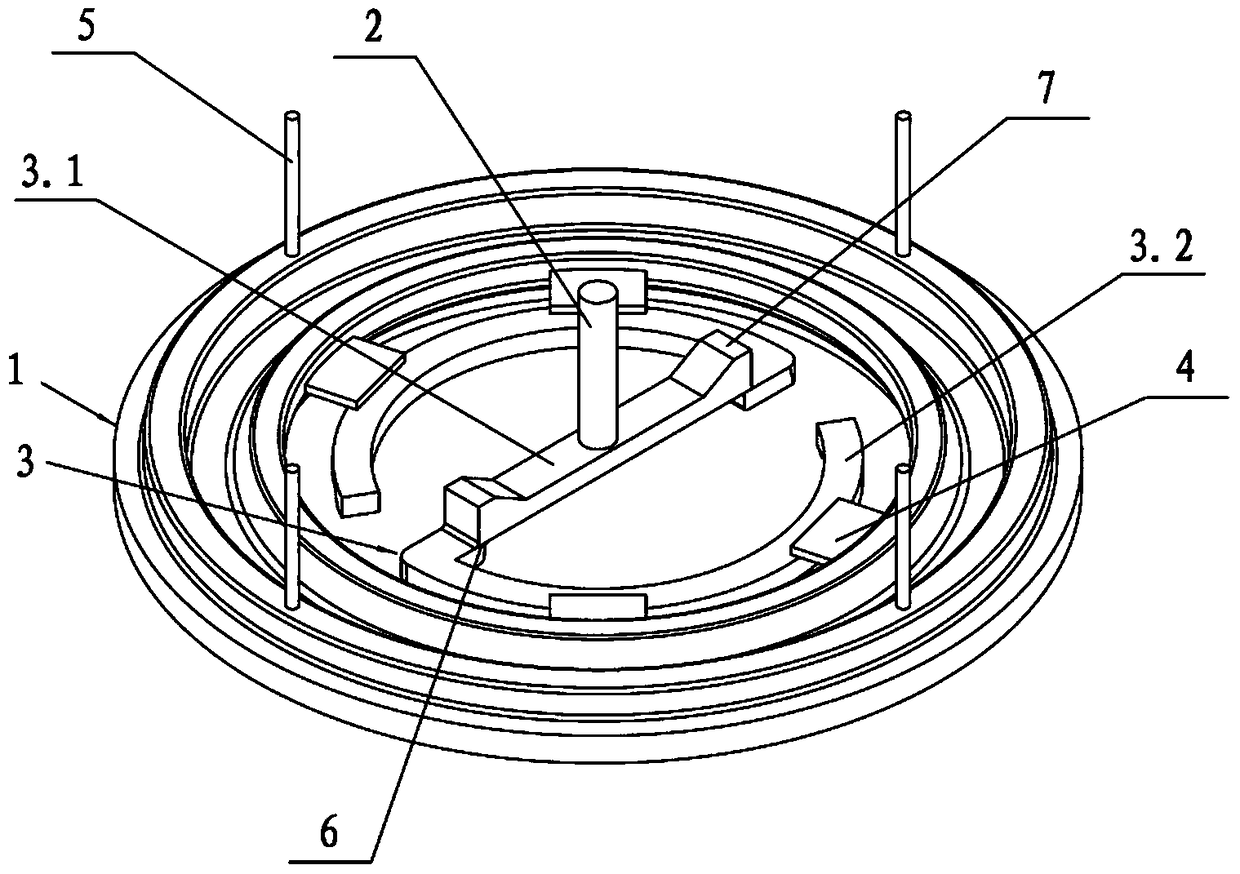

The pouring system and pouring method of thin-walled castings

A pouring system and thin-walled casting technology, applied in the direction of casting mold, casting mold composition, casting molding equipment, etc., can solve the problems of low casting yield and yield, high production cost, unstable control, etc., and achieve high yield , Low production cost, the effect of shortening the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Incubate with flow, the pouring temperature is 1350°C, and the pouring speed is 320kg / min. All the rest are the same as the prior art. The metallographic image of the prepared product is shown in figure 2 shown.

Embodiment 2

[0030] Incubate with flow, the pouring temperature is 1380°C, and the pouring speed is 300kg / min. The metallographic image of the prepared product is shown in image 3 shown.

Embodiment 3

[0032] Incubate with flow, the pouring temperature is 1390°C, and the pouring speed is 280kg / min. The metallographic image of the prepared product is shown in Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com