Direct-connected full-electric injection plasticizing and driving system

A drive system, all-electric technology, applied in the field of new injection plasticization drive system, can solve the problems affecting the precision of injection molding machine, injection molding performance, injection speed, contact wear between screw and barrel, and the quality of injection molding table is not in the middle, so as to reduce weight, The effect of reducing screw wear and avoiding vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

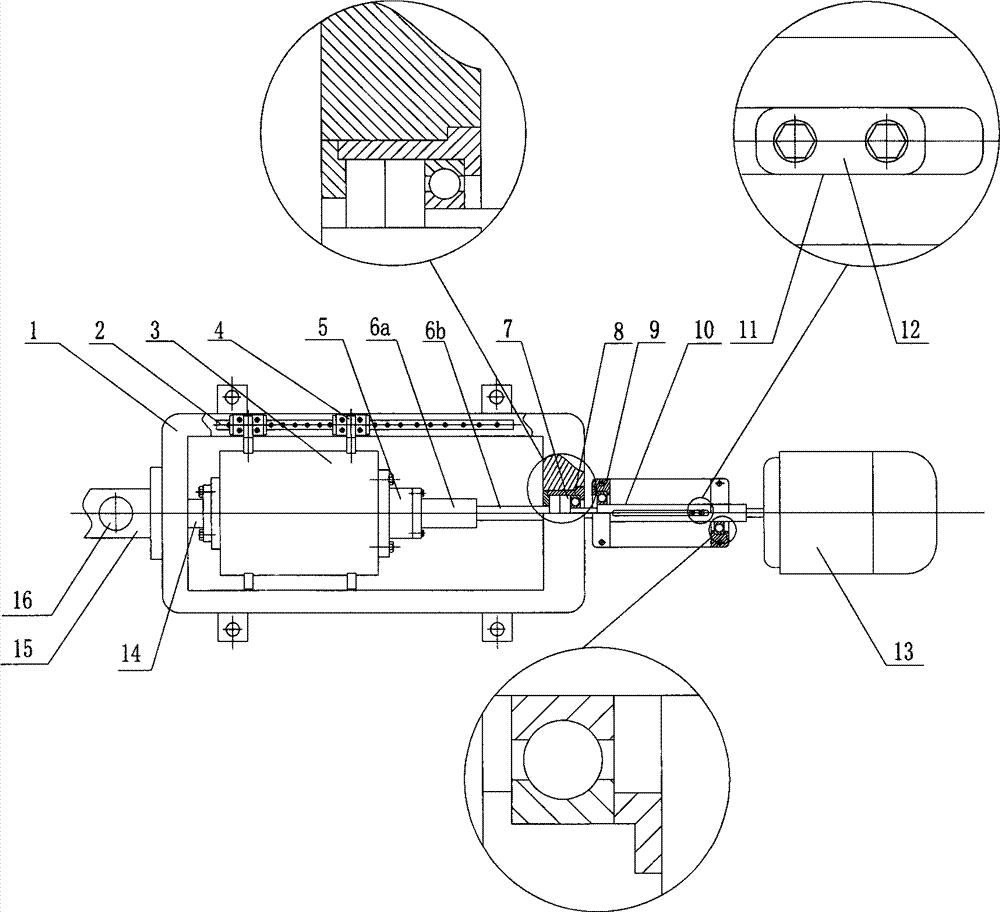

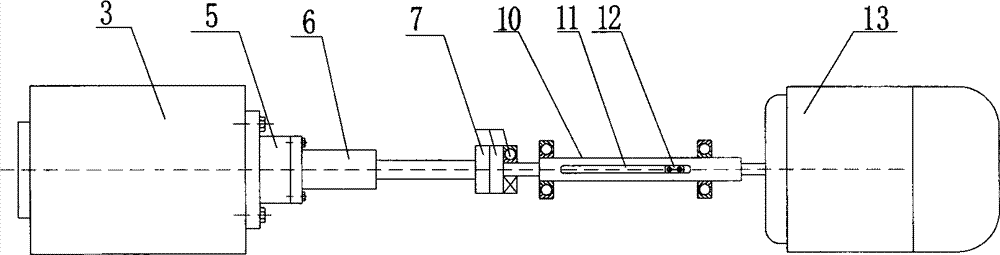

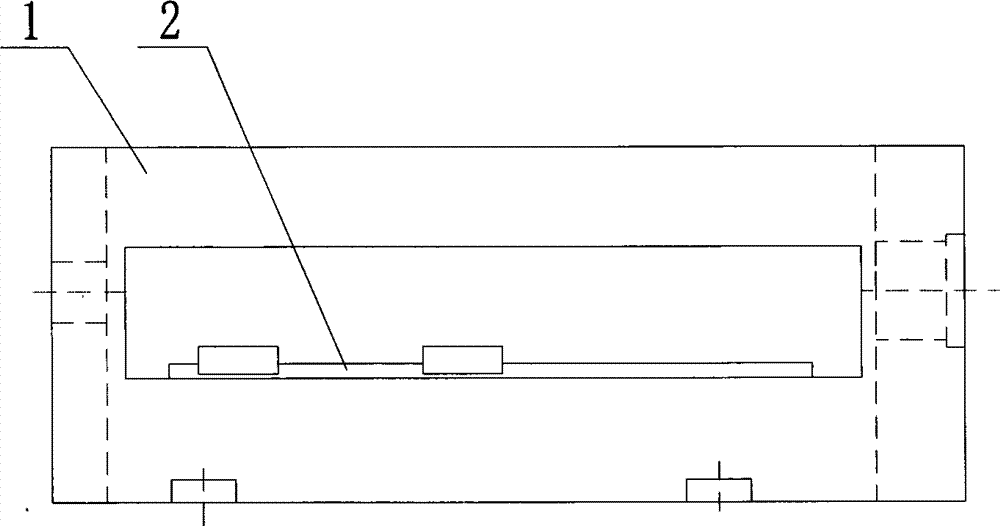

[0018] The present invention proposes a direct-connected all-electric injection plasticization drive system, such as figure 1 As shown, the device includes a rectangular injection table 1, a linear guide rail 2, an annular torque motor 3, a rib plate 4, a connection plate 5, a ball screw nut 6a, a ball screw screw 6b, a bearing 7, a bearing sleeve 8, and a mold transfer sleeve Cylinder support table 9, mold transfer sleeve 10, chute 11, bump 12, servo motor 13, screw rod 14, machine barrel 15 and feed inlet 16. Among them, the rectangular injection table 1 is a rectangular frame, such as image 3 and 4 As shown, there are two rectangular through holes on the side of the rectangular injection table 1, and a linear guide rail 2 is fixed on each through hole, circular holes are opened in the axial direction on the front and rear frames of the rectangular injection table, and the screw The end of 14 extends into the rectangular injection table 1 through the hole on the front fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com