Material conveying and material dividing device of belt conveyor

A material distribution device and belt conveyor technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as belt scratches, shorten the service life of conveyor belts, and material accumulation in distributors, so as to reduce workload and labor intensity , material distribution effect is ideal, and the effect of equipment recovery is fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

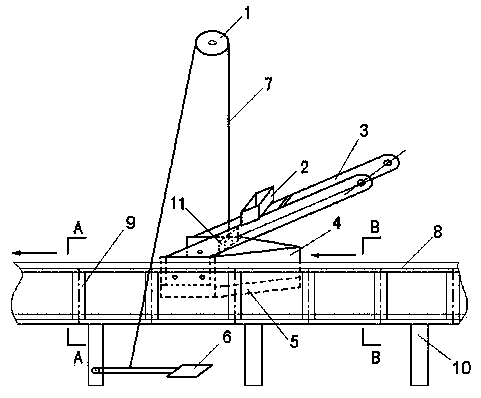

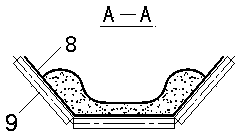

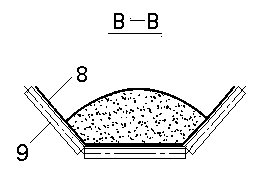

[0012] The material distributor is further described below in conjunction with the accompanying drawings and embodiments. like figure 1 As shown, the material conveying and distributing device of the belt conveyor includes a frame 10 and a guide wheel 9 installed on the frame 10. The guide wheel 9 is equipped with a conveyor belt 8. It is characterized in that a fixed pulley 1 is installed above the frame 10. , the conveyor belt 8 is equipped with a distributor 4, one end of the distributor 4 is an isosceles triangle, and the other end is a rectangle. One end of the conveyor belt 8 is facing the output direction of the conveyor belt 8. The two sides of the distributor 4 are rectangular and are connected to one end of the connecting arm 3. The connecting arm 3 is provided with a counterweight box 2 and an ear piece 11, and one end of the wire rope 7 is connected to the ear piece. 11. The other end is connected to the pedal 6 through the fixed pulley 1, and the pedal 6 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com