Special high-wettability resin for colour mixing

A high wettability, resin technology, applied in the field of coating resin, can solve the problems of inconsistent particle size, specific gravity, floating powder, uneven color, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

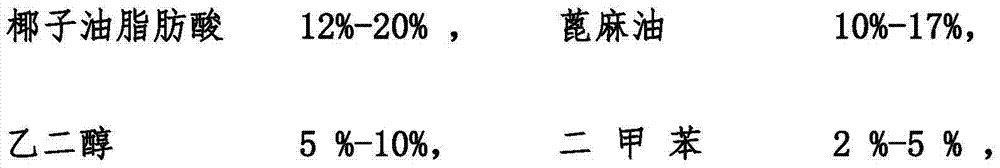

[0017] A kind of special resin with high wettability for toning, the raw material composition of its weight percentage is:

[0018]

[0019] A kind of special resin with high wettability for toning, its manufacture method is as follows:

[0020] (1) Check whether the reactor is clean, whether the bottom valve is closed, try to check whether the cooling water systems are normal, and whether the equipment is normal;

[0021] (2) Pump coconut oil fatty acid, castor oil, ethylene glycol, and xylene into the reactor in order, accurately weigh the antioxidant on a small scale with a plastic bucket, add and disperse evenly from the manhole after dilution;

[0022] (3) Put pentaerythritol, trimethylolpropane, and phthalic anhydride into the reactor in turn, cover the manhole, and open the heating system to raise the temperature after 10 minutes of CO25L / min;

[0023] (4) Turn on the vertical and horizontal cooling water and continue to heat up until it reaches about 110°C and stir...

Embodiment 2

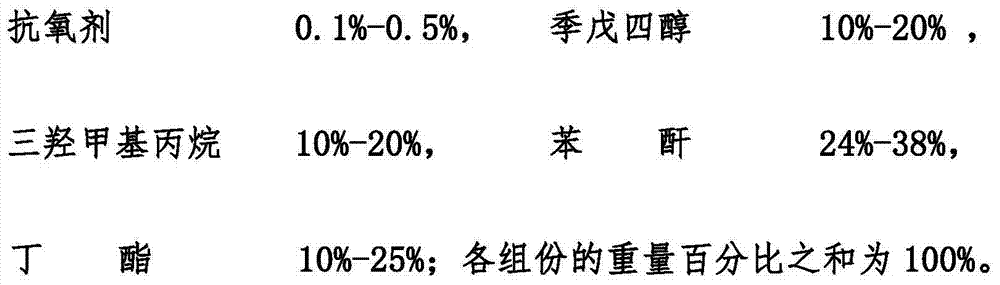

[0028] A kind of special resin with high wettability for toning, the raw material composition of its weight percentage is:

[0029]

Embodiment 3

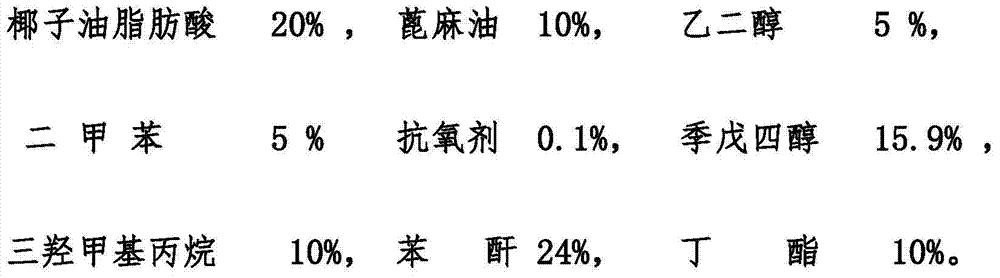

[0031] A kind of special resin with high wettability for toning, the raw material composition of its weight percentage is:

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com