Polyurea waterproof coating, preparation method and use method thereof and carbamide resin

A technology of waterproof coating and polyurea resin, which is applied in the field of coatings, can solve the problems of weak adhesion and low mechanical strength, and achieve excellent water resistance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

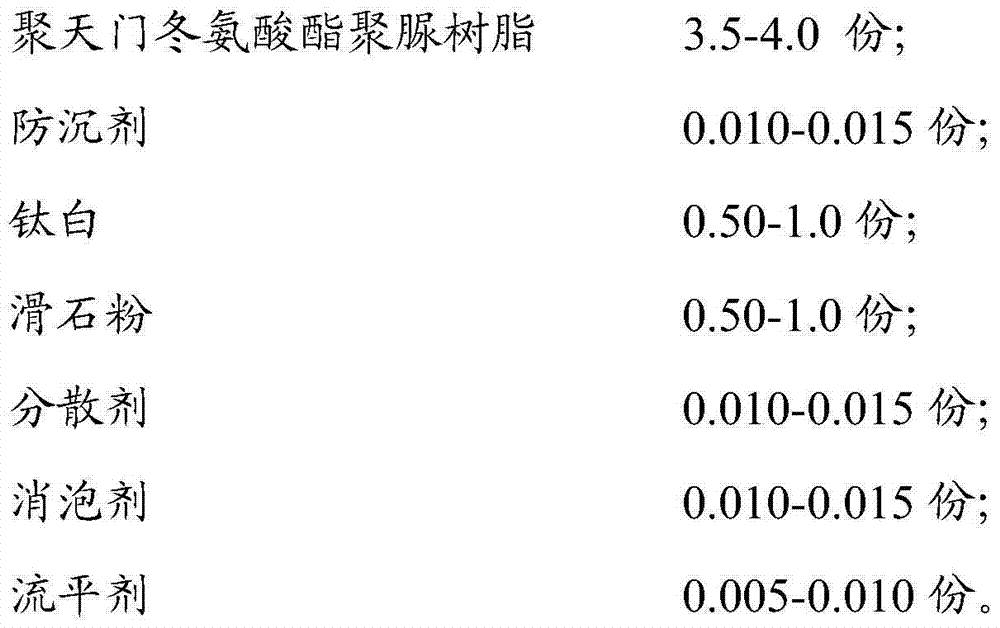

[0033] Correspondingly, the present invention also provides the preparation method of above-mentioned polyurea waterproof coating, and described preparation method comprises the following steps:

[0034] Step S01: Obtain each component according to the components and contents in the polyurea waterproof coating;

[0035] Step S02: performing the first mixing treatment on polyaspartate polyurea resin, anti-sedimentation agent, titanium dioxide, and dispersant to obtain a mixed material;

[0036] Step S03: adding talcum powder, defoamer and leveling agent to the mixed material for a second mixing process.

[0037] In the above step S01, the components of the polyurea waterproof coating are as described above, and will not be repeated here to save space.

[0038] Preferably, the polyaspartic acid ester polyurea resin can be obtained by reacting diethyl maleate and polyether amine at 45-55°C as described above, diethyl maleate and polyether amine The weight ratio of polyetheramin...

Embodiment 1

[0046] A method for distributing components of a polyurea waterproof coating and a preparation method thereof, the polyurea waterproof coating contains the following components by weight:

[0047]

[0048]

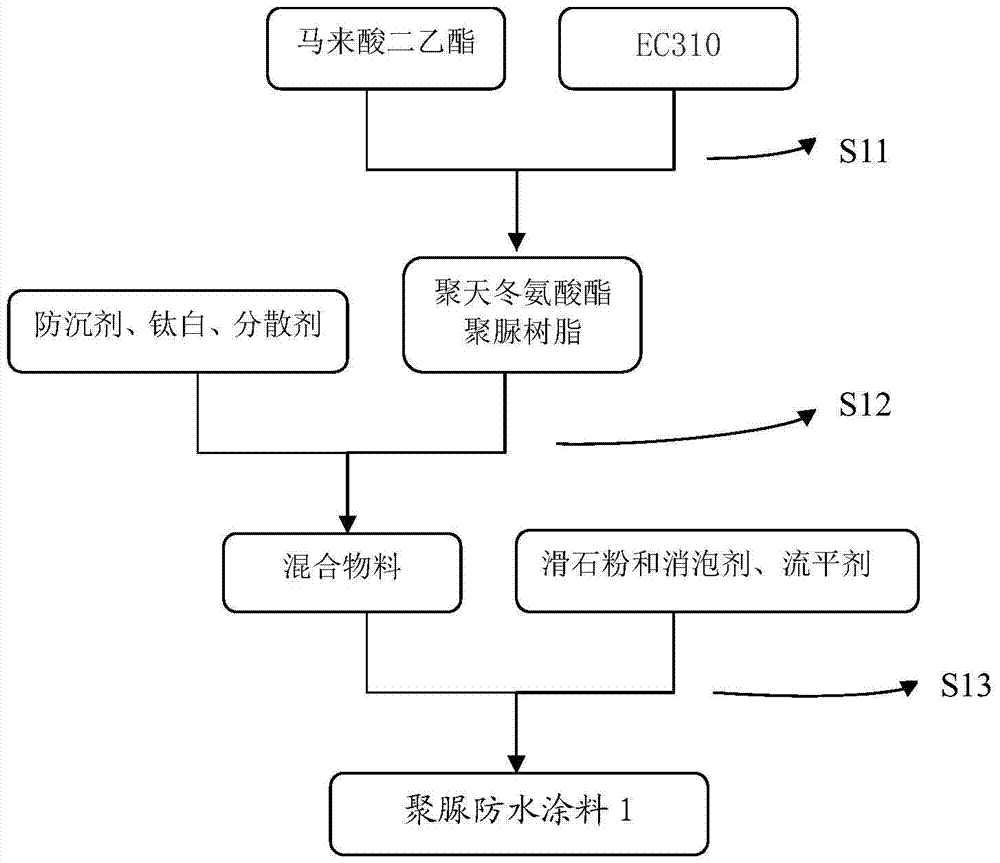

[0049] Its preparation method technological process is as follows figure 1 As shown, it includes the following steps:

[0050] S11. Add diethyl maleate and polyetheramine EC310 with a weight ratio of 1.80:1.63 in the reactor, raise the temperature to 55°C, react for 72 hours under stirring, and cool down to room temperature to obtain polyaspartate polyurea resin;

[0051] S12. Add anti-settling agent, titanium dioxide, and dispersant to the polyaspartate polyurea resin in step S11, stir and disperse at high speed for 25 minutes to obtain a mixed material;

[0052] S13. After reducing the rotational speed, add talcum powder, defoamer, and leveling agent to the mixed material obtained in step S12, stir for 15 minutes, discharge the material, and pack to obtain a poly...

Embodiment 2

[0054] A polyurea waterproof coating component formula and a preparation method thereof. The polyurea waterproof coating contains the following components by weight:

[0055]

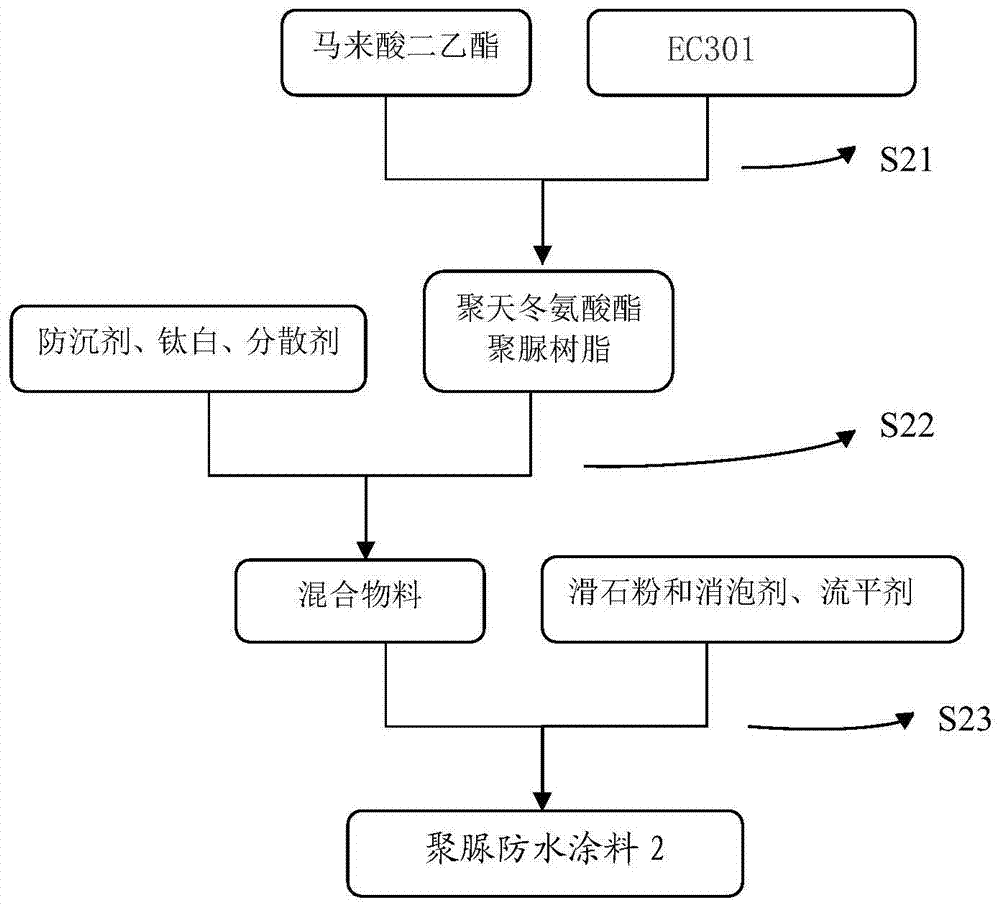

[0056] Its preparation method technological process is as follows figure 2 As shown, it includes the following steps:

[0057] S21. Add diethyl maleate and polyetheramine EC301 in a weight ratio of 1.80:1.70 to the reactor, raise the temperature to 45°C, react for 72 hours under stirring, and cool down to room temperature to obtain polyaspartate polyurea resin;

[0058] S22. Add anti-settling agent, titanium dioxide, and dispersant to the polyaspartate polyurea resin in step S21, and stir and disperse at high speed for 25 minutes to obtain a mixed material;

[0059] S23. After reducing the rotating speed, add talcum powder, defoamer, and leveling agent to the mixed material obtained in step S22, stir for 15 minutes, discharge the material, pack, and obtain polyurea waterproof coating 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com