Acidity and alkalinity control method for dry anaerobic fermentation of straws

A dry anaerobic, control method technology, applied in the field of waste recycling, can solve the problems of organic acid accumulation, fermentation, failure, etc.

Inactive Publication Date: 2015-04-08

NORTHEAST AGRICULTURAL UNIVERSITY

View PDF2 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to provide a method for controlling the acidity and alkalinity of straw dry anaerobic fermentation to solve the problem of fermentation failure caused by the accumulation of organic acids in the straw dry anaerobic fermentation system

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

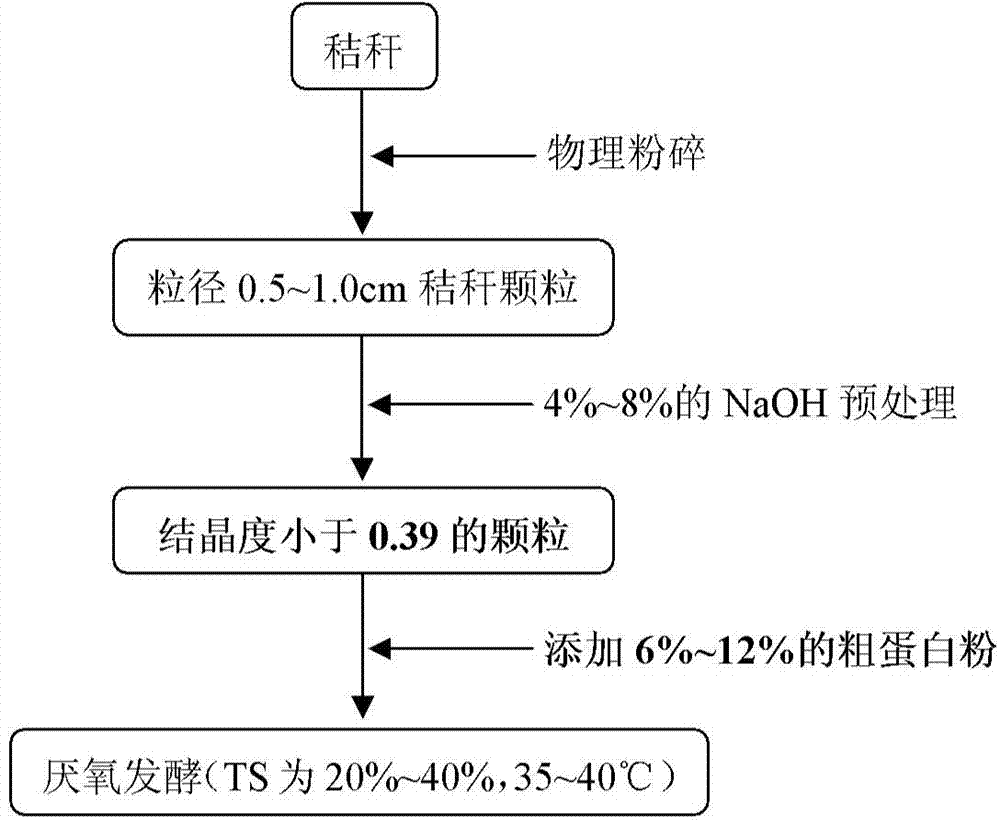

[0020] A) pulverize the straw of crops to straw particles with a particle size of 0.5-2.0 cm;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses an acidity and alkalinity control method for dry anaerobic fermentation of straws. The method comprises the following steps: A) crushing the straws into straw pellets; B) mixing an NaOH solution with the straw pellets evenly, pretreating the materials until the crystallinity is smaller than 0.39; C) adding crude protein powder to the pretreated straw pellets, mixing evenly and adjusting the total solid with water; and D) fermenting the materials obtained from the step C) at 35-40 DEG C. According to the method disclosed by the invention, the problem of fermentation failure due to organic acid accumulation, which is easily caused by nutritional imbalance of substances in the individual dry anaerobic fermentation process of the straws can be effectively avoided.

Description

technical field [0001] The invention belongs to the technical field of waste recycling, and in particular relates to a method for controlling the pH of straw dry anaerobic fermentation. Background technique [0002] As a big agricultural country, my country's annual output of straw is about 700 million tons, ranking first in the world, and it is increasing at an annual rate of 6%. A large amount of agricultural straw, if not properly handled, will have a serious impact on the surrounding environment. At present, the main treatment methods of straw include incineration, feed, ethanol production and anaerobic fermentation to produce biogas. Due to the obvious advantages of dry anaerobic fermentation treatment process, it can adapt to various sources of solid organic waste, with low operating costs, less or no water demand, less biogas slurry, and low follow-up treatment costs. No wet process scum, precipitation and other problems. Therefore, dry anaerobic fermentation can b...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C12P5/02

Inventor 魏自民赵越李英军席北斗陈斌李晨辰吴俊秋杨天学

Owner NORTHEAST AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com