Pellets prepared from blast furnace slag iron fine powder as well as preparation method and application of pellets

A technology of iron concentrate powder and blast furnace slag, which is applied in the field of pellets prepared from blast furnace slag iron concentrate powder and its preparation, can solve the problems of high energy consumption and complicated process, and achieve economic benefit improvement, good economic benefit, and time saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

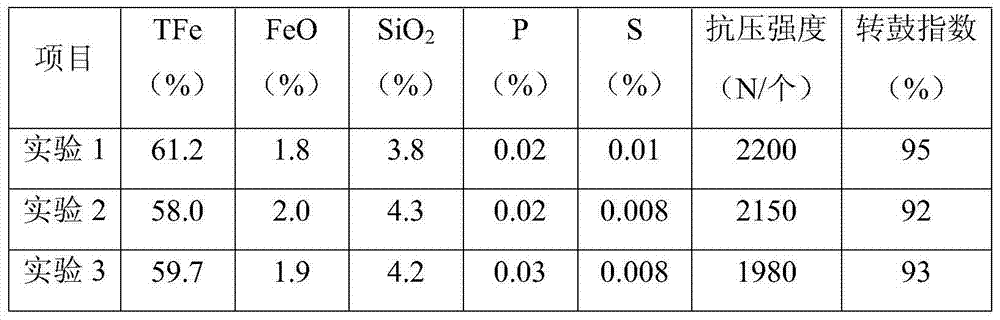

Examples

Embodiment

[0025] a, the blast furnace slag is crushed, sieved, ball milled, and magnetically separated to obtain fine iron powder, the iron content is 60-70%, and the particle size is 0.8mm-1.5mm, and the particle size of 25% of the iron fine powder in the obtained iron fine powder is 0.8mm-1mm;

[0026] b. Stir and mix the iron powder, water and binder with a multifunctional dough mixer, and stir for 2-3 minutes to mix evenly;

[0027] c. Use HYG367-80 high-pressure double-roller briquetting machine to press and form, the diameter of the briquette is 550mm, and place it at room temperature for 4 days to dry to obtain pellets;

[0028] The binding agent described in step b is the mixture of the Yilong brand cold-setting pellet binder and clay produced by Zibo Yilong Chemical Co., Ltd.; the Yilong brand cold-setting pellet produced by Zibo Yilong Chemical Co., Ltd. in the binder The added amount of the binder is 0.5-1% of the weight of the iron fine powder, the added amount of the clay ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com