83kg-grade sapphire crystal furnace crystal-growing structure and crystal-growing method

A sapphire crystal, 83kg technology, applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems affecting the quality of sapphire crystal products, difficult to mass production, difficult to guarantee high temperature, etc., to achieve suitable for mass production, Production method optimization, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

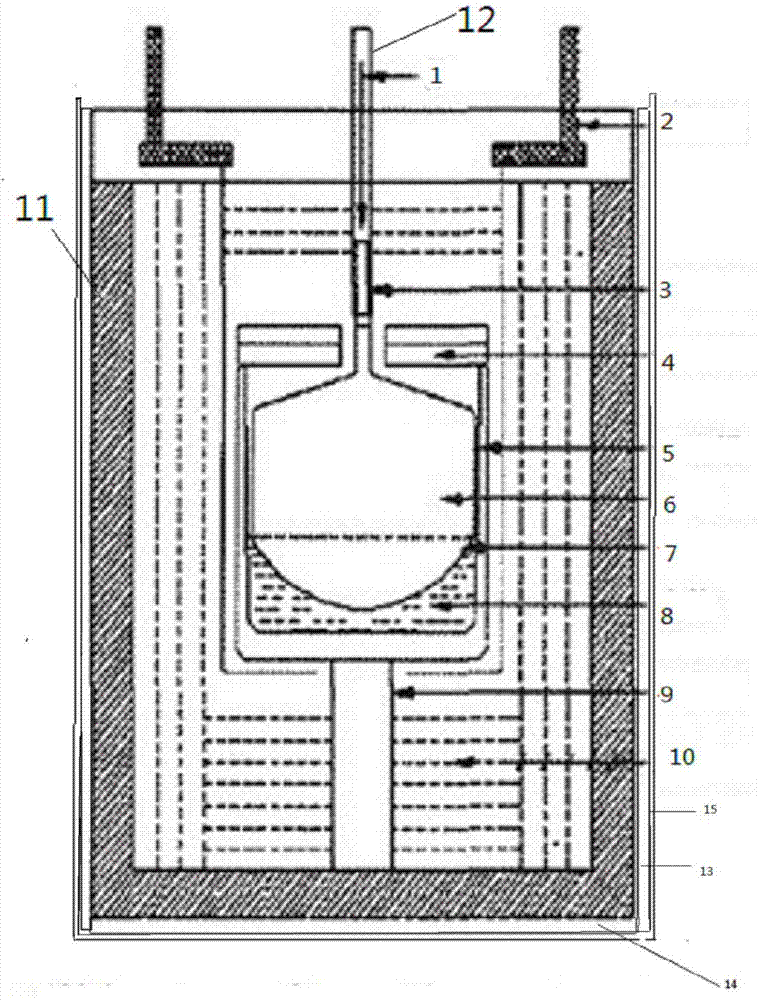

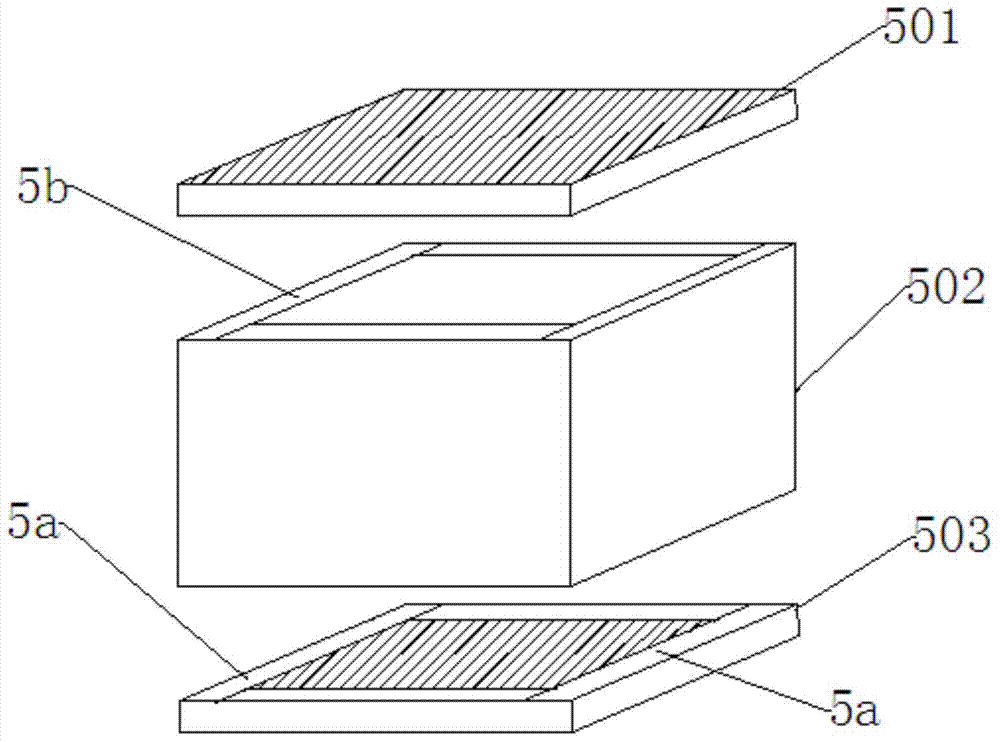

[0035] like figure 1 As shown, an 83kg grade sapphire crystal furnace crystal growth structure, heat exchanger 1, heater 2, seed crystal chuck 3, crucible 5, support shaft 9, insulation layer 10, tungsten cylinder 11 and seed crystal rod 12, side Screen 13, zirconium brick 14, furnace cylinder 15;

[0036] The crucible 5 is arranged in the tungsten cylinder 11, the support shaft 9 is arranged between the bottom surface of the crucible 5 and the tungsten cylinder 11, the top cover of the crucible 5 is provided with a through hole, the heat exchanger 1 is arranged in the seed crystal rod 12, and the seed crystal rod The bottom end of 12 is provided with a seed crystal clamp 3, the seed crystal rod 12 passes through the upper cover of the tungsten cylinder 11 and extends into the tungsten cylinder 11, and the seed crystal clamp 3 is located above the through hole of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com