Double-liquid stirring grouting system

A grouting system and dual-liquid grouting technology, which are applied in drilling pipes, casings, buildings, etc., can solve the problems of unstable grouting pressure and difficult forming of single-liquid grouting piles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

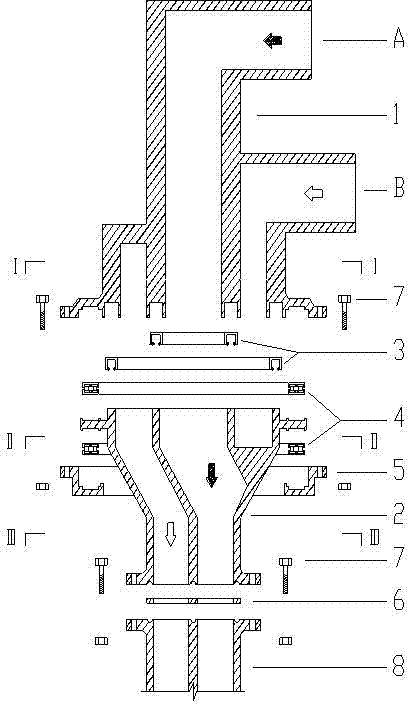

[0023] Such as figure 1 As shown, the channel conversion part includes two specially processed and formed parts, which are the upper channel conversion part (1) and the lower channel conversion part (2). The upper passage conversion part (1) is connected to the grouting pipe and remains fixed, and the lower passage conversion part (2) rotates with the drill pipe.

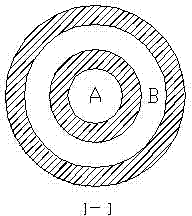

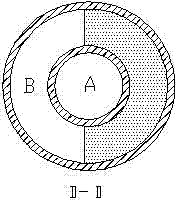

[0024] exist figure 1 Among them, the upper channel conversion part (1) includes two slurry flow channels A and B. In order to meet the requirement that the slurry delivery channel rotates with the drill pipe, the cross-sectional form of the A and B channels is converted from two parallel grouting holes to a circular shape. Combined with the circular ring, the I--I section view is as follows figure 2 As shown, the circular passage A and the annular passage B, the upper passage conversion part (1) is provided with the embedding groove of the rotating high-pressure sealing ring (3) and the plane bearing (4) and fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com