A reinforced grouting casing for improving the bearing capacity of steel members

A technology of steel components and bearing capacity, which is applied in building structure, building maintenance, construction, etc., can solve the problems of structural safety and normal use function impact, and achieve the effect of relatively high construction accuracy, short construction period, and improved bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

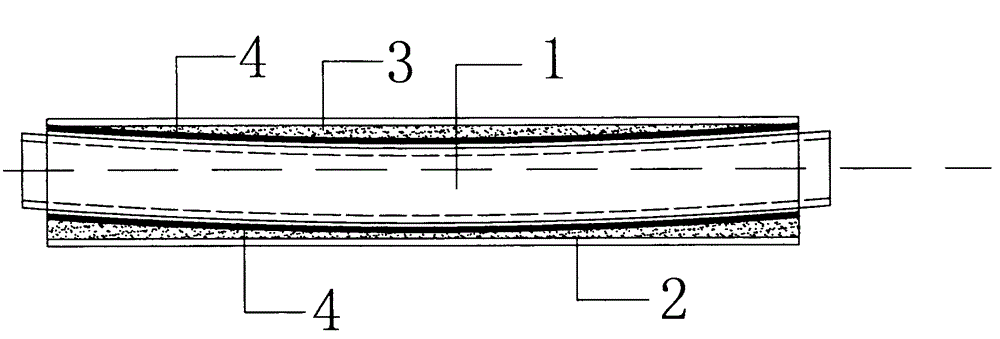

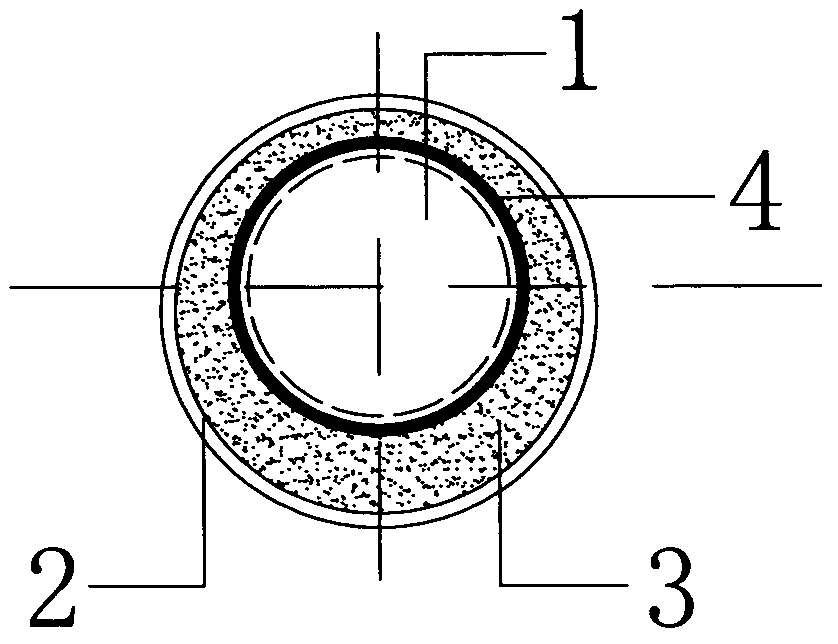

[0012] Such as figure 1 Shown: the originally straight steel member 1 is bent and deformed, and the center line of the steel member 1 is bent to form an arc. The flexible material membrane 4 is wrapped outside the buckling part of the steel member, and the straight sleeve 2 is set outside the flexible material membrane 4. When installing, the straight sleeve 2 can be cut into two parts in the axial direction in advance. The two parts of the straight sleeve Parts are respectively buckled outside the steel member 1 wrapped with a flexible material film 4, and the butt joints are connected on site. The connection method can be welding or bolts and other existing connection methods. Of course, other methods can also be used to cover the sleeve 2 on the steel member 1. outside. The construction accuracy of the suit is not high, and it only n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com