Waterproof curtain wall for foundation pit

A technology for water-stop curtains and foundation pits, applied in infrastructure engineering, construction, etc., can solve the problems of high cost, unsuitable soil quality, easy to pollute the environment, etc., and achieve the effect of reducing requirements, strong adaptability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

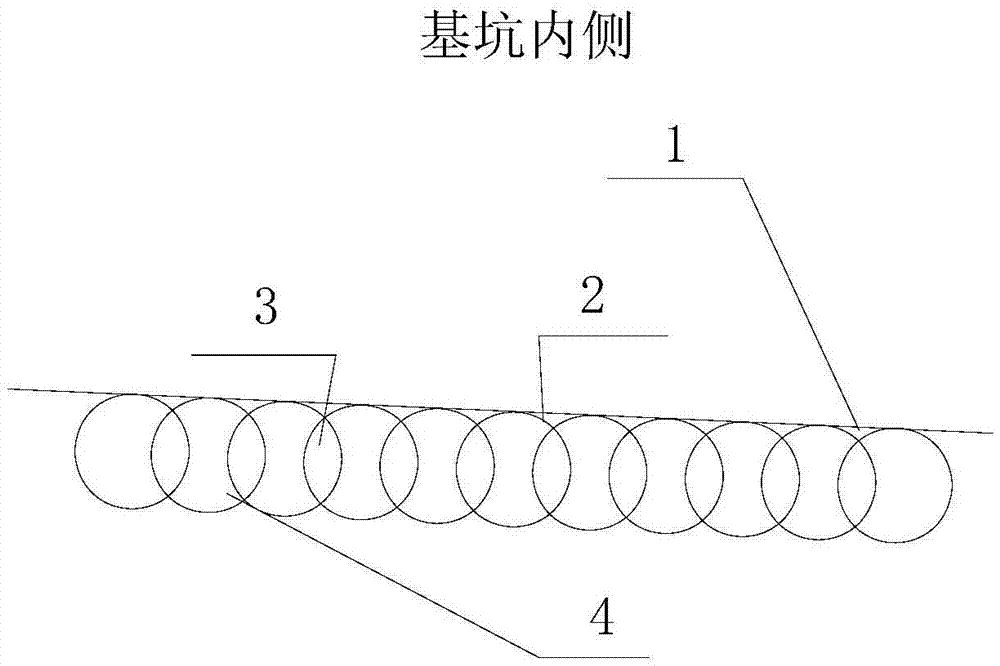

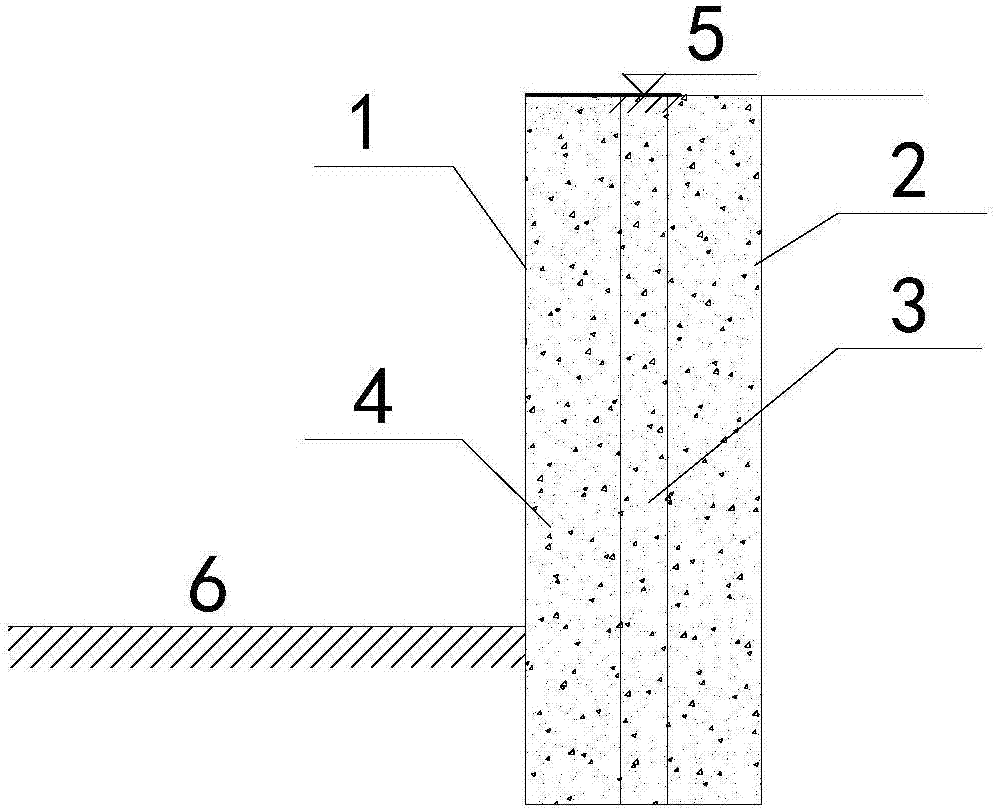

[0025] refer to figure 1 , 2 As shown, a water-stop curtain wall of a foundation pit is provided with a layer of water-stop curtain wall 4 composed of several high-pressure rotary grouting piles 2 outside the foundation pit, and the pile bottoms of each high-pressure rotary grouting pile 2 are placed below the bottom of the foundation pit. In the permeable stratum, the adjacent high-pressure jet-spray piles 2 of the water-stop curtain wall 4 on the same floor are engaged with each other, and the joint 3 of the high-pressure jet-spray piles 2 is 1 / 3-1 / 2 of the pile diameter.

Embodiment 2

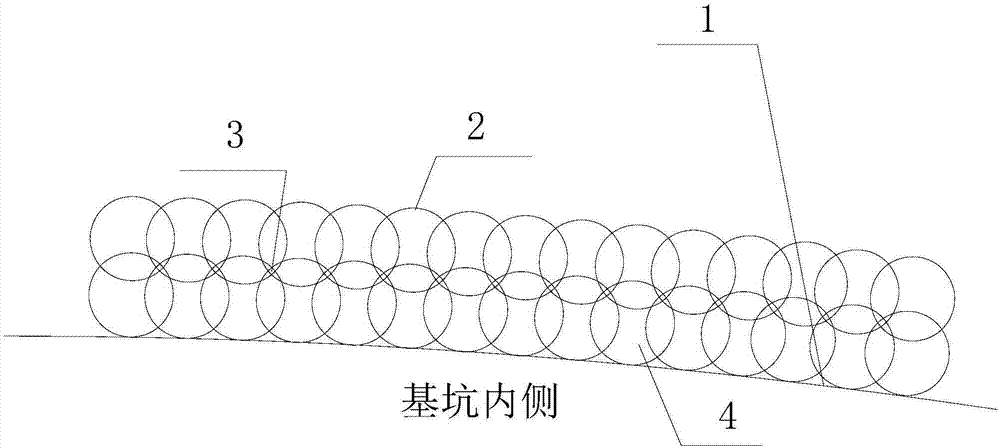

[0027] refer to image 3 As shown, a water-stop curtain wall of a foundation pit is provided with two layers of water-stop curtain walls 4 composed of several high-pressure rotary grouting piles 2 on the outside of the foundation pit, and the bottoms of each high-pressure rotary grouting piles 2 are placed below the bottom of the foundation pit. In the permeable stratum, the adjacent high-pressure rotary grouting piles 2 of the water-stop curtain wall 4 on the same layer are engaged with each other, and the adjacent high-pressure rotary grouting piles 2 between the water-stop curtain walls 4 of adjacent layers are also engaged with each other, and the high-pressure rotary grouting The occlusal part 3 of the pile 2 is 1 / 4-1 / 3 of the diameter of the pile. The four adjacent high-pressure jet grouting piles 2 of adjacent layers of water-stop curtain walls 4 are engaged with each other.

Embodiment 3

[0029] refer to Figure 4 As shown, this embodiment is basically the same as Embodiment 2, and the difference is that three adjacent high-pressure jet grouting piles 2 of adjacent layers of water-stop curtain walls 4 are engaged with each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com