Air source heat pump drying machine fully recycling exhaust waste heat

An air source heat pump and dryer technology, applied in the field of dryers, can solve the problems of non-recovery or less recovery of heat, the operating efficiency of the unit is not fully exerted, and the energy consumption is large, so as to achieve reasonable structure and solve high energy consumption. and pollution discharge problems, the effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

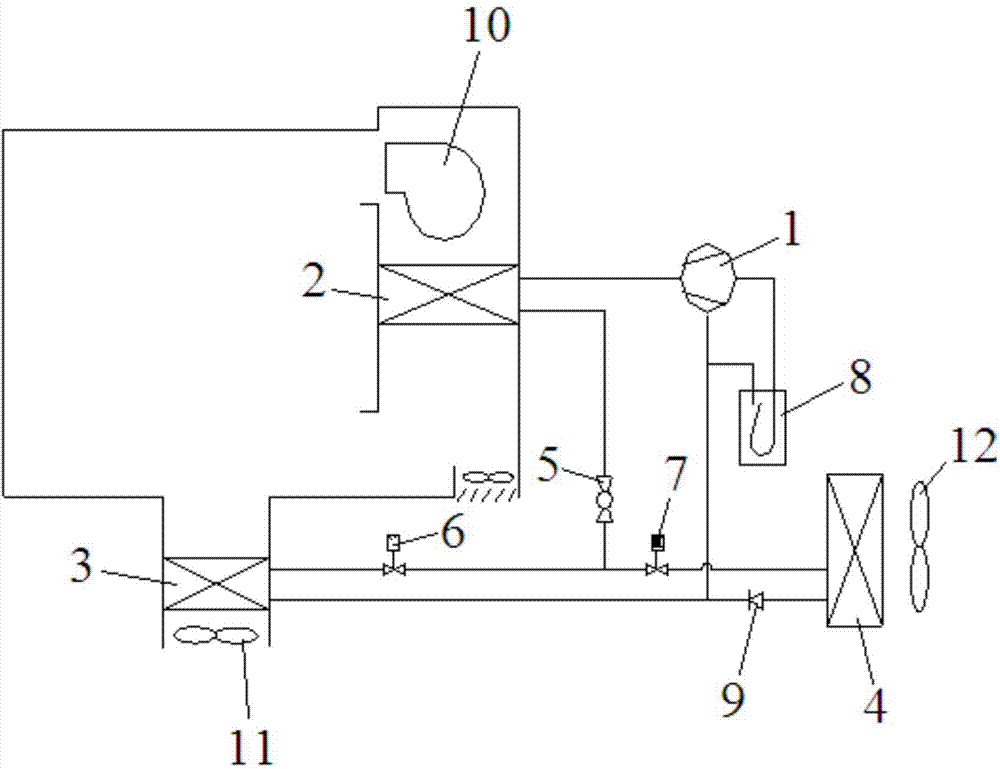

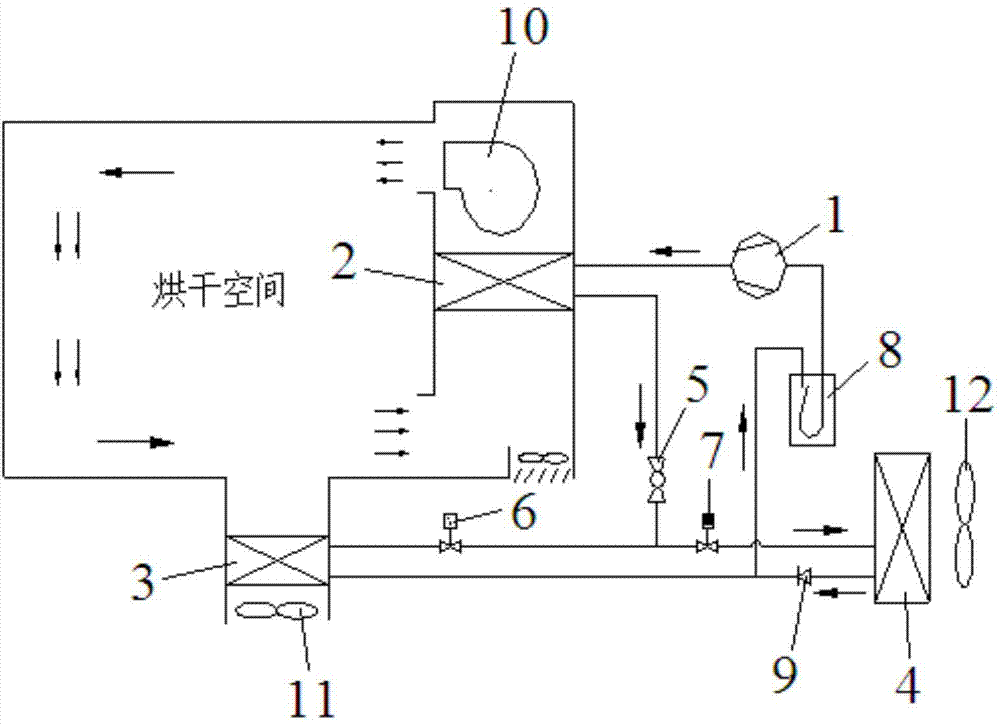

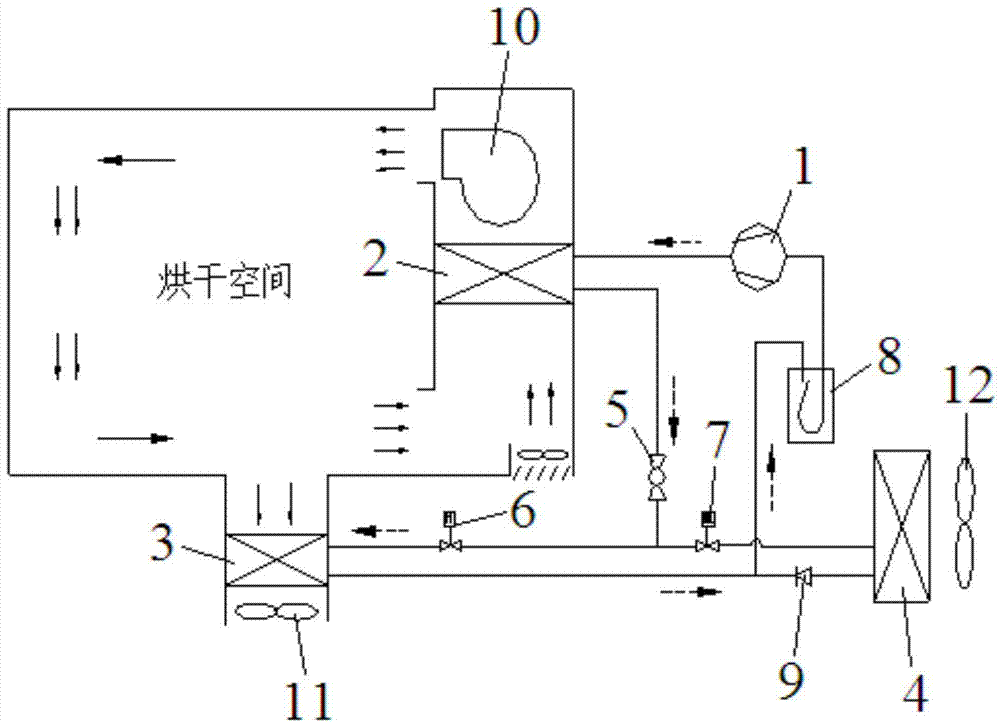

[0013] see figure 1 , an air source heat pump dryer that fully recovers exhaust waste heat, including a compressor 1, first and second internal air heat exchangers 2, 3, external air heat exchanger 4, expansion valve 5, first and second Solenoid valves 6, 7, one-way valve 9, gas-liquid separator 8, temperature and humidity sensing components and controller, the outlet of compressor 1 is connected to one side interface of the first internal air heat exchanger 2, the first internal The other side interface of the air heat exchanger 2 is connected with the expansion valve 5 and then divided into two branches, one of which is connected with the first electromagnetic valve 6 and the second internal air heat exchanger 3 in turn, and the other branch is It is connected with the second solenoid valve 7, the external air heat exchanger 4 and the one-way valve 9 in turn, and the ends of the two branches converge in one place and are connected with one end of the gas-liquid separator 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com