Electric-control drawing force detector

A technology of pulling force and detector, which is applied in the field of precision parts detection and can solve problems such as inability to provide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

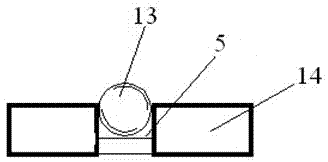

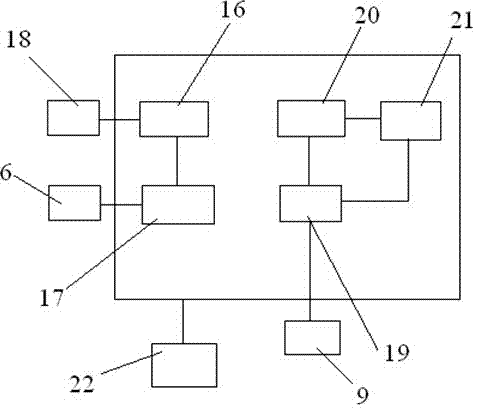

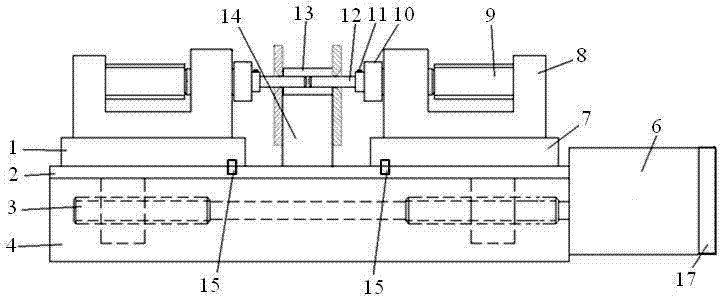

[0044] The electronically controlled pullout force detector in the present embodiment is as figure 1 and figure 2 As shown, it includes a base 4 and a slide rail 2 installed on the base 4 . Two sliding tables are installed on the slide rail 2, which are respectively a left sliding table 1 and a right sliding table 7, and a measuring head seat 8 is respectively installed on the left sliding table 1 and the right sliding table 7, and the two Each of the probe bases 8 is respectively clamped in the probe base positioning grooves on the left slide 1 and the right slide 7; each probe base 8 is provided with a detection ferrule 12. The clamping head 10 and the force sensor 9, wherein the detection ferrule 12 is fastened and fixed on one side of the clamping head 10 by a locking screw 11, and the other side of the clamping head 10 is connected to the The force sensor 9 is connected, and the clamping head 10 is also floatingly connected with the probe base 8; the detection ferrules...

Embodiment 2

[0061] The electronically controlled pullout force detector in the present embodiment is as figure 1 and figure 2 As shown, it includes a base 4 and a slide rail 2 installed on the base 4 . Two sliding tables are installed on the slide rail 2, which are respectively a left sliding table 1 and a right sliding table 7, and a measuring head seat 8 is respectively installed on the left sliding table 1 and the right sliding table 7, and the two Each of the probe bases 8 is respectively clamped in the probe base positioning grooves on the left slide 1 and the right slide 7; each probe base 8 is provided with a detection ferrule 12. The clamping head 10 and the force sensor 9, wherein the detection ferrule 12 is fastened and fixed on one side of the clamping head 10 by a locking screw 11, and the other side of the clamping head 10 is connected to the The force sensor 9 is connected, and the clamping head 10 is also floatingly connected with the probe base 8; the detection ferrule...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com