Selective solar heat absorption coating with low emission ratio and preparation method for selective solar heat absorption coating

A technology of solar heat and absorbing coatings, applied in photovoltaic power generation, climate sustainability, final product manufacturing, etc., can solve the problems of limited coating thickness, low emissivity ratio, unfavorable mass production, etc. Excellent performance and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

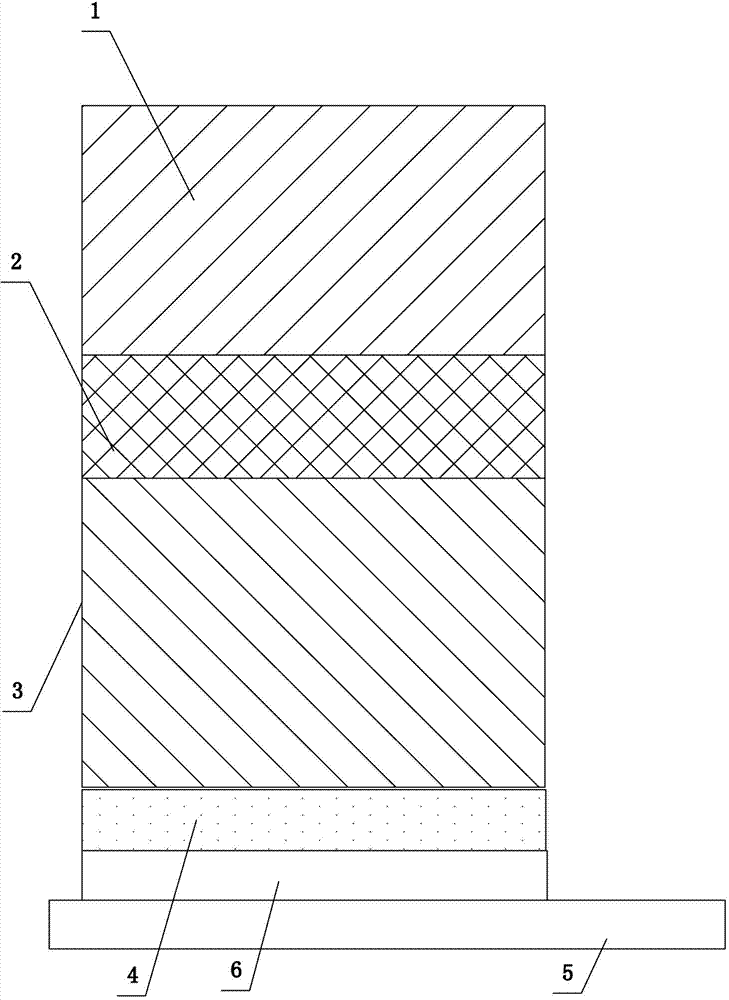

[0031] A method for preparing a selective solar heat absorbing coating, comprising the following steps:

[0032] Step 1. Using DC magnetron sputtering process or AC magnetron sputtering process, aluminum strip, stainless steel strip or copper strip is used as metal strip substrate 5, and a layer is plated on the metal strip substrate 5 for improving and Thin-film coating 6 for improving adhesion and / or corrosion resistance of selective solar heat absorbing coatings, wherein the thin-film coating 6 consists of at least one metal, at least one metal oxide, at least one metal nitride , at least one metal oxynitride or any combination of the above metals, metal oxides, metal nitrides and metal oxynitrides.

[0033] Step 2, using a large-area electron beam evaporation coating process, using aluminum, copper or silver as the evaporation material, and coating a layer of high reflection base layer 4 on the thin film coating 6 prepared in step 1.

[0034] Step 3. Using electron beam e...

Embodiment 1

[0041] An antireflection layer based on a TCO material, comprising a TCO transparent conductive oxide coating 2 as a secondary antireflection layer and a SiO2 (SiOx) oxide coating 1 as a main antireflection layer, the SiO2 (SiOx) The oxide coating 1 covers the TCO transparent conductive oxide coating 2 . The TCO transparent conductive oxide coating 2 is prepared by a DC magnetron sputtering process using a composite TCO target. The SiO2 (SiOx) coating is prepared by using electron beam evaporation or AC magnetron sputtering process. The composite TCO target is a metal oxide or a mixture of metal oxides. The composite TCO target material is ZnO:Al2O3 (AZO).

[0042] In this embodiment, AZO, a semi-conductive coating material with a high refractive index, can replace the secondary anti-reflection layer material in the middle sub-layer structure of the traditional selective solar heat absorption coating film system. Compared with the sub-anti-reflection layer material (usually...

Embodiment 2

[0045] An antireflection layer based on a TCO material, comprising a TCO transparent conductive oxide coating 2 as a secondary antireflection layer and a SiO2 (SiOx) oxide coating 1 as a main antireflection layer, the SiO2 (SiOx) The oxide coating 1 covers the TCO transparent conductive oxide coating 2 . The TCO transparent conductive oxide coating 2 is prepared by a DC magnetron sputtering process using a composite TCO target. The SiO2 (SiOx) coating is prepared by using electron beam evaporation or AC magnetron sputtering process. The composite TCO target is a metal oxide or a mixture of metal oxides. The composite TCO target is ZnO:Ga2O3 (GZO).

[0046] In this embodiment, GZO, a semi-conductive coating material with a relatively high refractive index, can replace the secondary anti-reflection layer material in the middle sub-layer structure of the traditional selective solar heat absorption coating film system. Compared with the sub-anti-reflection layer material (usual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com