Electrode material of mesh shaped titanium oxide film, manufacturing method thereof, and application thereof

A titanium oxide film and electrode material technology, applied in electrical components and other directions, can solve the problems that ions are difficult to reach the decomposition state, the autolysis is violent and unstable, and the discharge effect is not good, and the charging efficiency is increased, the mesh interval is small, and the cost reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

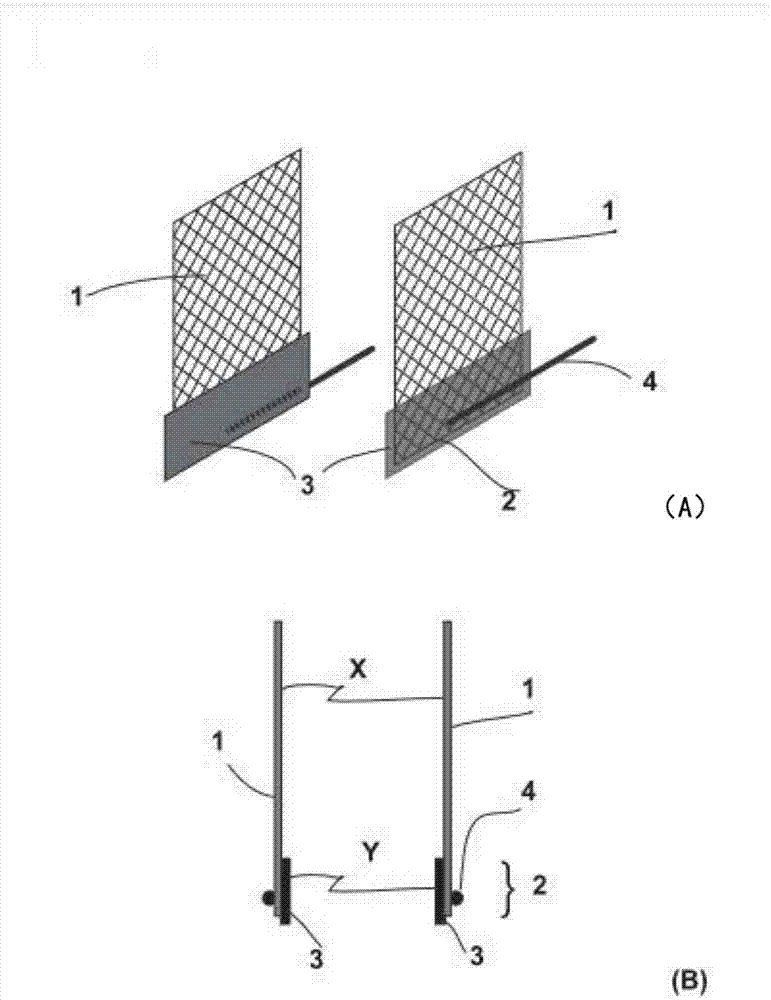

[0034] figure 1 It is an explanatory diagram of a manufacturing method of an electrode material of a mesh-shaped titanium oxide film according to the present invention, (A) is a perspective view, and (B) is a front view.

[0035] The electrode material manufacturing method of the present invention: the mesh member 1 is made of a titanium conductive linear material, and a pair of mesh members 1 and 1 are arranged so as to face each other at a distance. Then, at the same peripheral portion of the mesh-shaped part 1, at the end of the thread material, the protruding needle point is outside the mesh-shaped part. When the mesh-shaped part 1 is used as an electrode, it can be discharged by this protruding end. .

[0036] The lower end of the above-mentioned mesh parts 1, 1 is installed with a metal plate 5;

[0037] Also, on the surface facing the metal plates 5, 5, a dielectric 3 made of ceramic resin, polyimide resin, or silicone resin is provided. The metal plates 5, 5 constit...

Embodiment 2

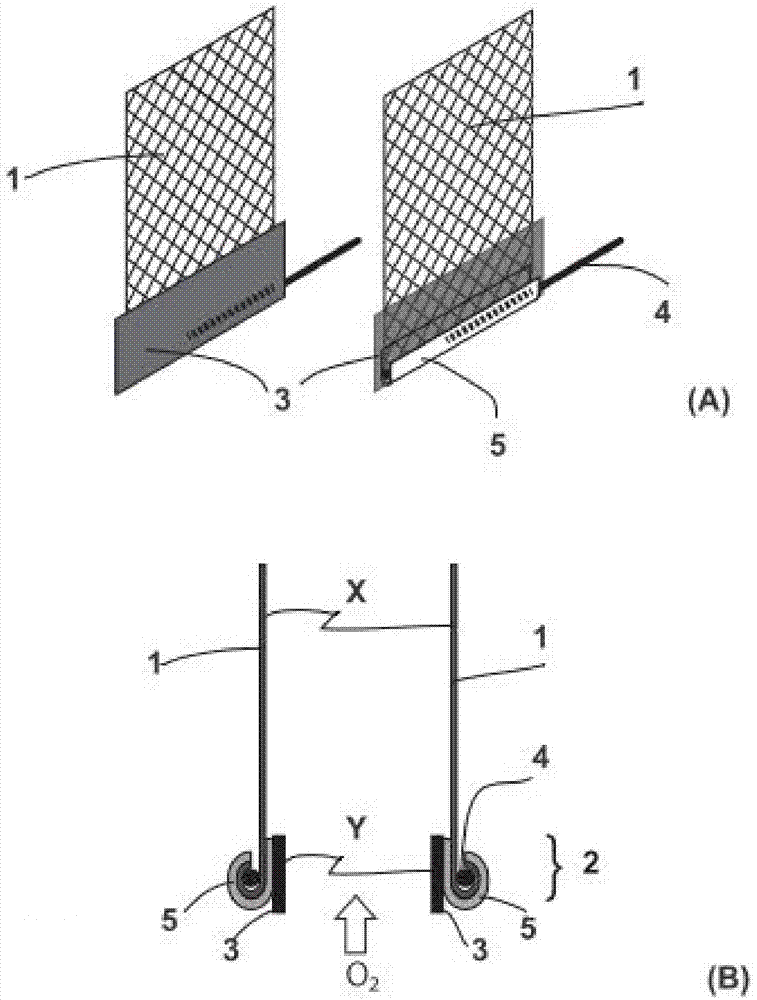

[0044] exist figure 2In the shown embodiment, a pair of mesh-shaped parts 1 are placed at a distance and arranged opposite to each other; then, the lower end of the mesh-shaped parts 1 and the same peripheral portion are provided with power supply leads 4, and at the end of the wire-shaped material , the protruding needle point is outside the mesh-shaped part 1. When the mesh-shaped part 1 is used as an electrode, the protruding end can discharge; the pair of mesh-shaped parts 1 are made of titanium conductive linear material ;

[0045] Dielectric 3 is set to the lower end of the mesh-shaped part, and the lower end constitutes a pair of grid discharge electrodes 2, and the discharge between the mesh-shaped parts 1 constitutes the mesh-shaped electrode 1, and when the discharge occurs between the mesh-shaped parts 1, A dielectric barrier discharge is generated between the barrier discharge electrodes 2 .

[0046] Compared with the first embodiment, the metal plate 5 is remov...

Embodiment 3

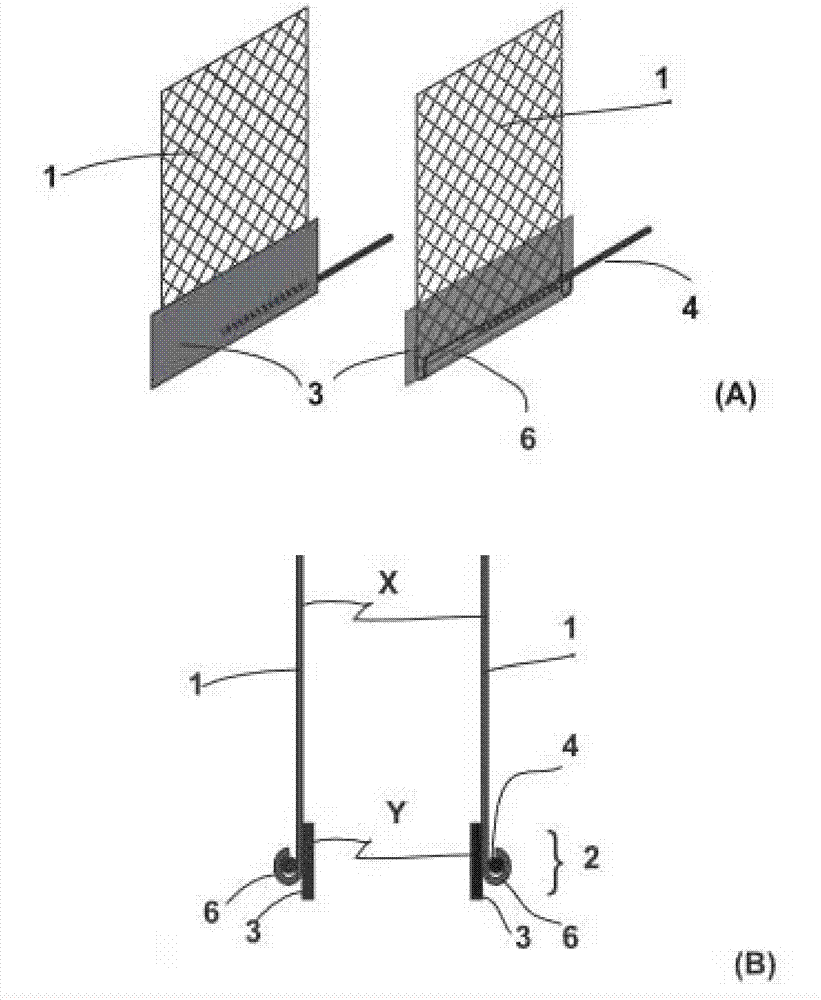

[0048] exist image 3 In the shown embodiment, the metal plate 5 is removed on the basis of the first embodiment, and the bent portion 6 is provided at the lower end of the mesh-shaped member 1, 1 to enclose the power supply lead 4, and the dielectric 3 is covered in the part including the bent portion 6. The portion where the dielectric 3 is provided constitutes the barrier discharge electrode 2 .

[0049] In the above examples, the dielectric material 3 of the mesh electrode 1 shows a different structure at the metal plate or grid discharge electrode 2, but in the following Figure 4 , showing a structure in which the dielectric is formed for the mesh member 1 itself.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com