Plasma all-dimensional vacuum coated power supply and coating method thereof

A vacuum coating and plasma technology, applied in the direction of ion implantation coating, vacuum evaporation coating, electrical components, etc., can solve the problems of power supply output parameters mismatch, poor coating quality, power supply is vulnerable to impact, etc., to reduce unit cost , good binding force, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

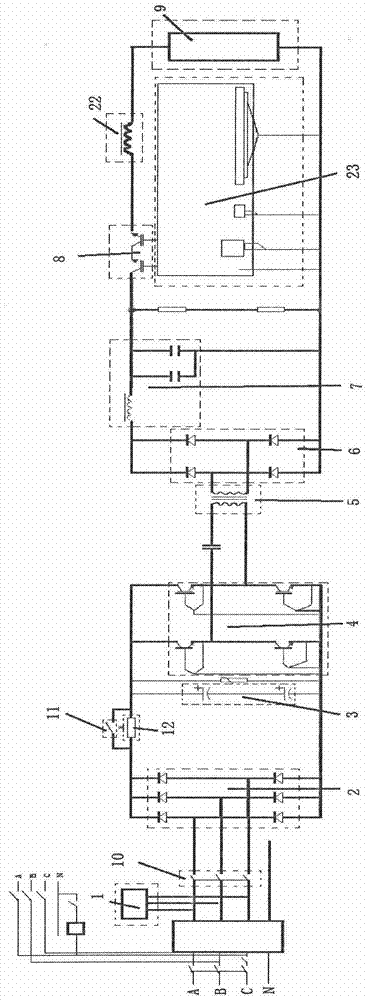

[0035] Such as Figures 1 to 6As shown, a plasma omnidirectional vacuum coating power supply includes a circuit for controlling the plasma omnidirectional vacuum coating power supply, and the circuit for controlling the plasma omnidirectional vacuum coating power supply also includes a filter 1, a rectifier circuit 2, a filter circuit 3, and a DC inverter Variable circuit 4, high-frequency step-up transformer 5, secondary rectification circuit 6, secondary filter circuit 7, IGBT chopping 8, plasma load 9, the input power is connected to the rectification circuit 2 through the filter 1, and the rectification circuit 2 is connected to the filter The circuit 3 is connected, the filter circuit 3 is connected with the DC inverter circuit 4, the DC inverter circuit 4 is connected with the high-frequency step-up transformer 5, the high-frequency step-up transformer 5 is connected with the secondary rectification circuit 6, and the secondary rectification circuit 6 is connected with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com