A kind of bismuth oxychloride-iron bismuth titanate composite photocatalyst and preparation method thereof

A bismuth oxychloride and photocatalyst technology, applied in the field of materials, can solve the problems of easy decomposition of harmful substances, low utilization rate of light energy, instability, etc., and achieve effective absorption and utilization of visible light, good catalytic effect, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

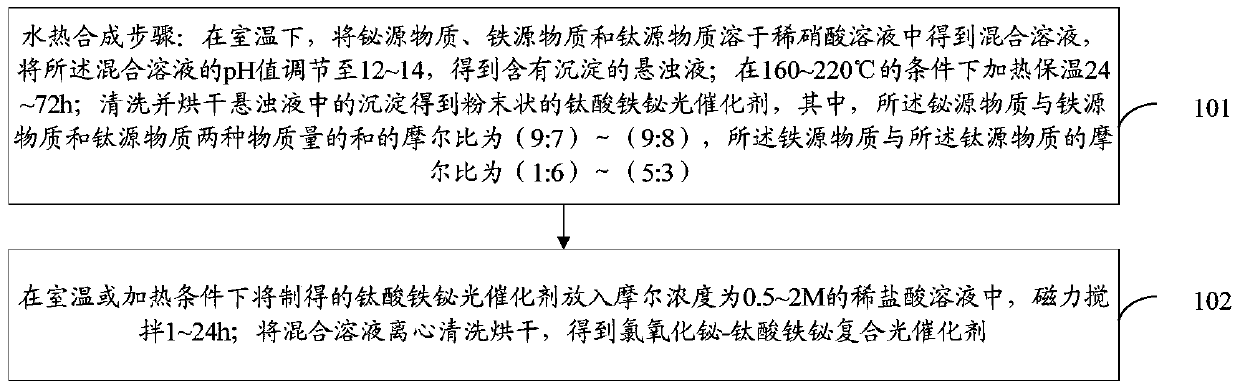

[0044] refer to figure 1 , which shows a flow chart of a preparation method embodiment of a bismuth oxychloride-iron bismuth titanate composite photocatalyst of the present invention, the method may specifically include:

[0045] Step 101, a hydrothermal synthesis step.

[0046] Dissolving bismuth source material, iron source material and titanium source material in dilute nitric acid solution at room temperature to obtain a mixed solution, adjusting the pH value of the mixed solution to 12-14 to obtain a suspension containing precipitates, and Heat at 160-220°C for 24-72 hours. Wash and dry the precipitate in the suspension to obtain powdered iron bismuth titanate photocatalyst. Wherein, the molar ratio of the bismuth source material to the sum of the iron source material and the titanium source material is (9:7) to (9:8), and the molar ratio of the iron source material to the titanium source material The ratio is (1:6)~(5:3).

[0047] Specifically, the amount of the iron s...

Embodiment 1

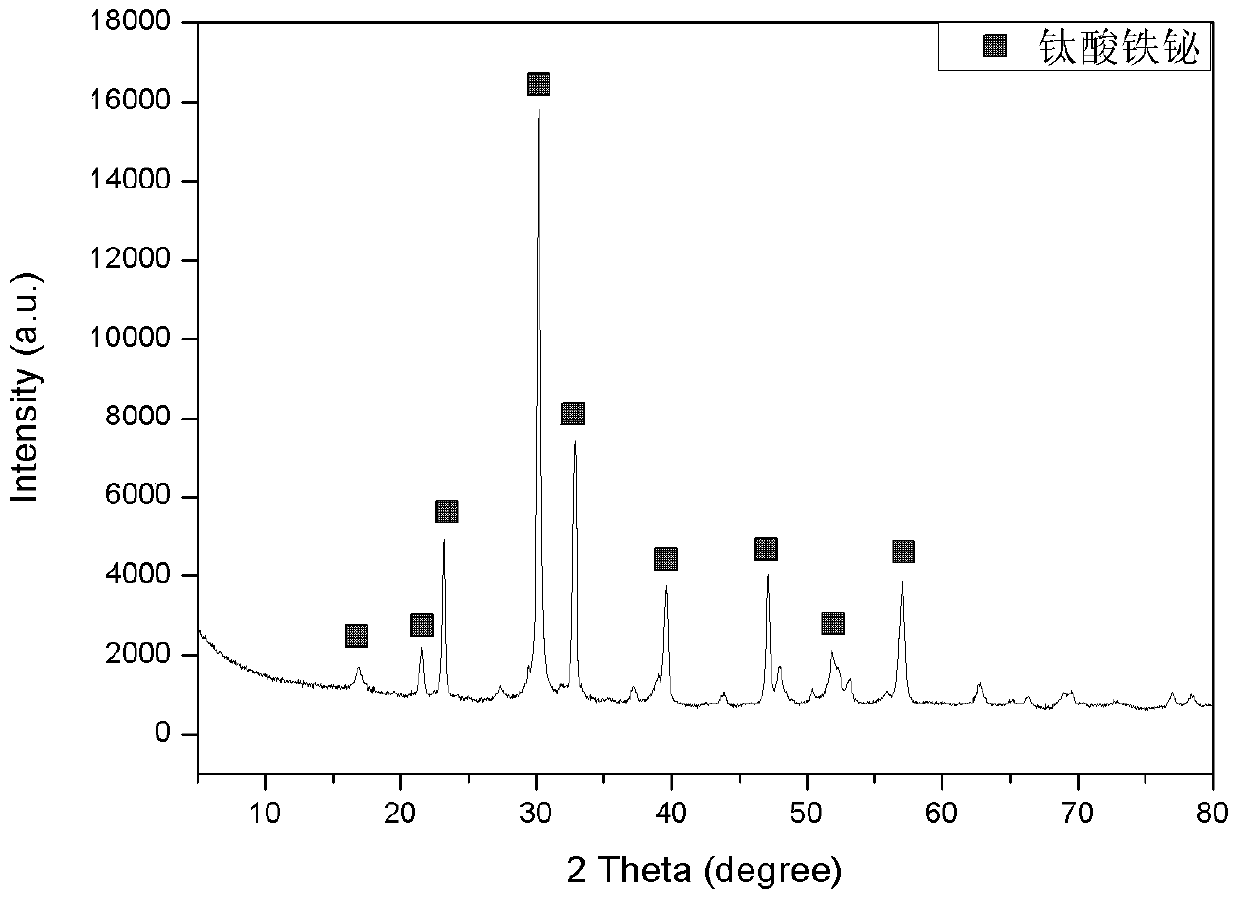

[0069] (1) At room temperature, BiCl 3 , FeCl 3 ·6H 2 O, TiCl 4 Soluble in 1M dilute nitric acid solution, the ratio of the amount of each raw material is n Bi :n Fe :n Ti =9:5:3. Then the pH value of the mixed solution was adjusted to 14 with 4M NaOH solution, and aged with stirring for 2 h. The suspension containing the precipitate was transferred to a reaction kettle and heated in an oven at 220°C for 24h. After the precipitate obtained by the hydrothermal method is centrifugally cleaned and dried, the obtained yellow powder product is the iron bismuth titanate photocatalyst.

[0070] (2) Dilute concentrated hydrochloric acid with a mass fraction of 36-38% to obtain a 2M dilute hydrochloric acid aqueous solution, take iron bismuth titanate powder, and put it into the 2M dilute hydrochloric acid solution with magnetic stirring for 1 hour. After a predetermined time, the mixed solution is centrifugally washed and dried, and finally the bismuth oxychloride-bismuth iron...

Embodiment 2

[0072] (1) At room temperature, the Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 O, C 16 h 36 o 4 Ti is dissolved in 2M dilute nitric acid solution, and the ratio of the amount of each raw material is n Bi :n Fe :n Ti =5:1:3. Then the pH value of the mixed solution was adjusted to 13.6 with 4M NaOH solution, and aged with stirring for 2 h. The suspension containing the precipitate was transferred to a reaction kettle and heated in an oven at 200°C for 48h. After the precipitate obtained by the hydrothermal method is centrifugally cleaned and dried, the obtained yellow powder product is the iron bismuth titanate photocatalyst.

[0073] (2) Dilute concentrated hydrochloric acid with a mass fraction of 36-38% to obtain 1M dilute hydrochloric acid aqueous solution, take iron bismuth titanate powder, put it into 1M dilute hydrochloric acid solution and magnetically stir for 9 hours. After a predetermined time, the mixed solution is centrifugally washed and dried, and finally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com