Method and device for fast detection of line current fault

A technology of line current and detection device, applied in directions such as fault location, can solve the problems of large delay of transmission signal and affect fast protection action, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

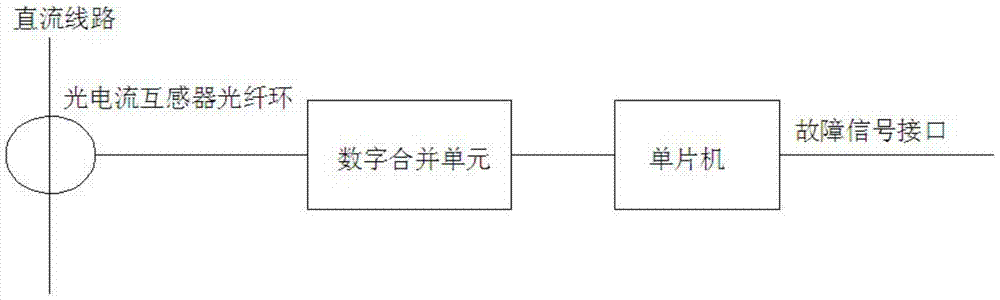

[0014] A method for quickly detecting line current faults comprises: a photocurrent sensor collects line current signals, and transmits the line current signals to a digital merging unit, and the digital merging unit transmits the processed line current signals to a single-chip microcomputer.

[0015] A line current fault fast detection device, comprising a photocurrent sensor, a digital merging unit, and a single-chip microcomputer; the output end of the photocurrent sensor is connected to the corresponding input end of the digital merging unit, and the output end of the digital merging unit is connected to the corresponding input end of the single-chip microcomputer.

[0016] Based on the above technical solutions and in conjunction with the accompanying drawings, the following specific implementation is given.

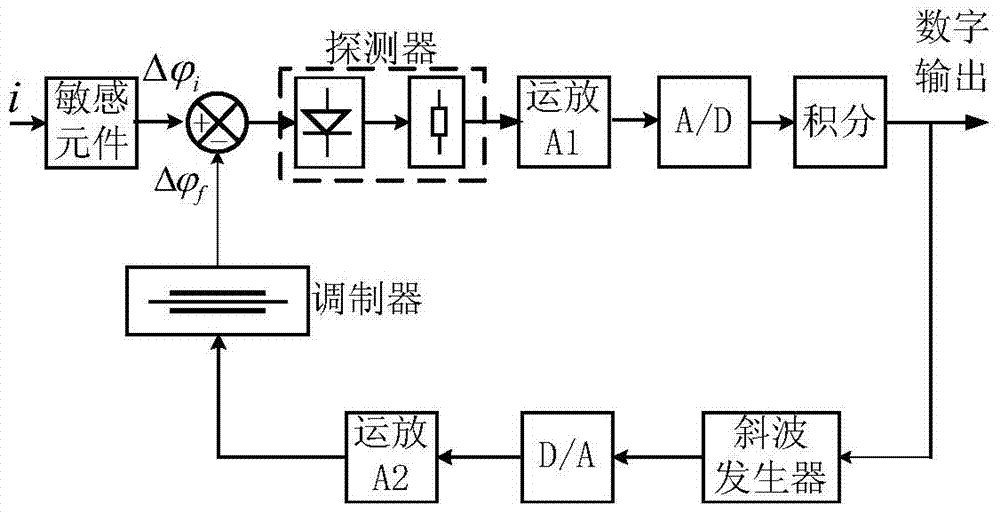

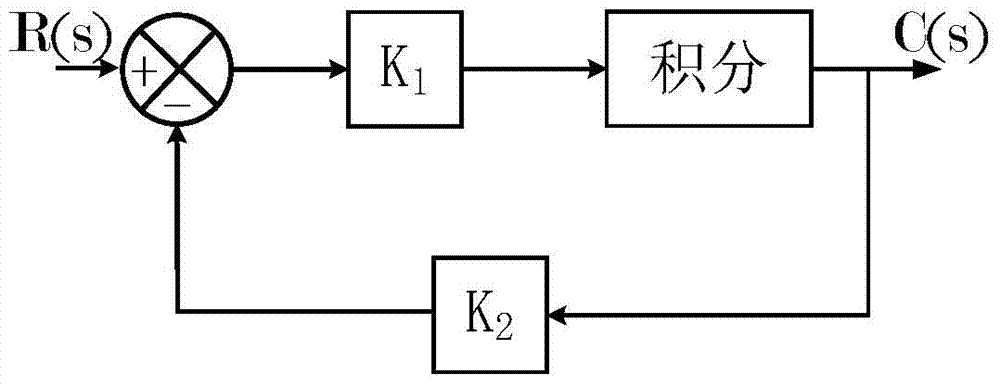

[0017] The photocurrent sensor and single-ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com