Image pickup element, method of manufacturing image pickup element, and electronic apparatus

A technology for image pickup components and pixels, which is applied in semiconductor/solid-state device manufacturing, electrical components, image communication, etc., can solve problems such as dark current and extinction, and achieve the effect of improving the interface state and suppressing dark current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, embodiments of the present disclosure will be described in detail with reference to the accompanying drawings. It should be noted that description will be made in the following order.

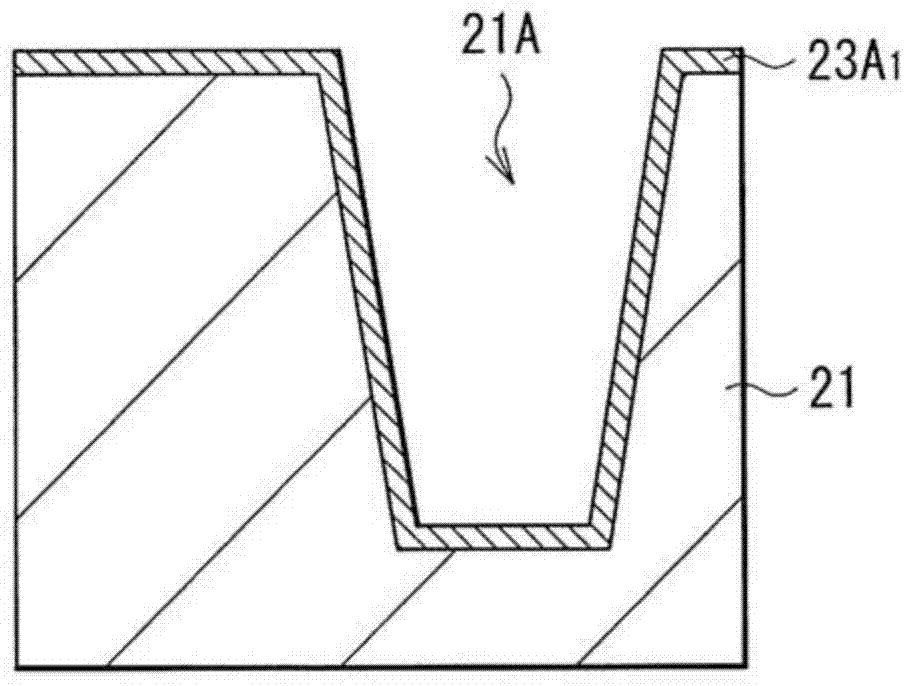

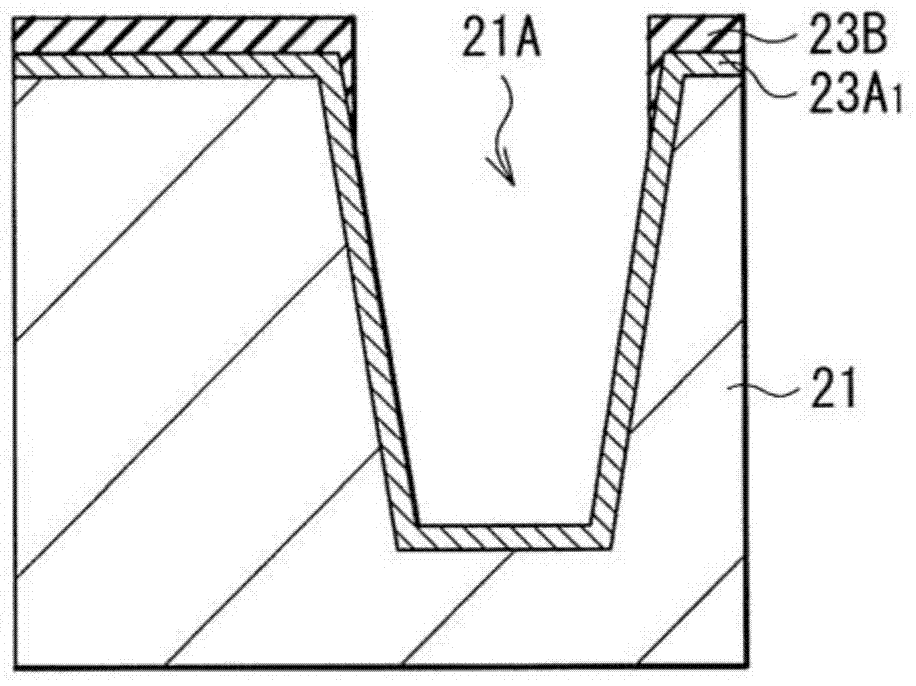

[0025] 1. Embodiment (Example in which the fixed-charge film has a multilayer structure, and each layer is formed using a different manufacturing method)

[0026] 2. Improvement (Example in which the light-shielding film is also provided in the pixel separation groove)

[0027] 3. Application examples (Application examples of solid-state image pickup devices and electronic equipment)

[0028] 1. Example

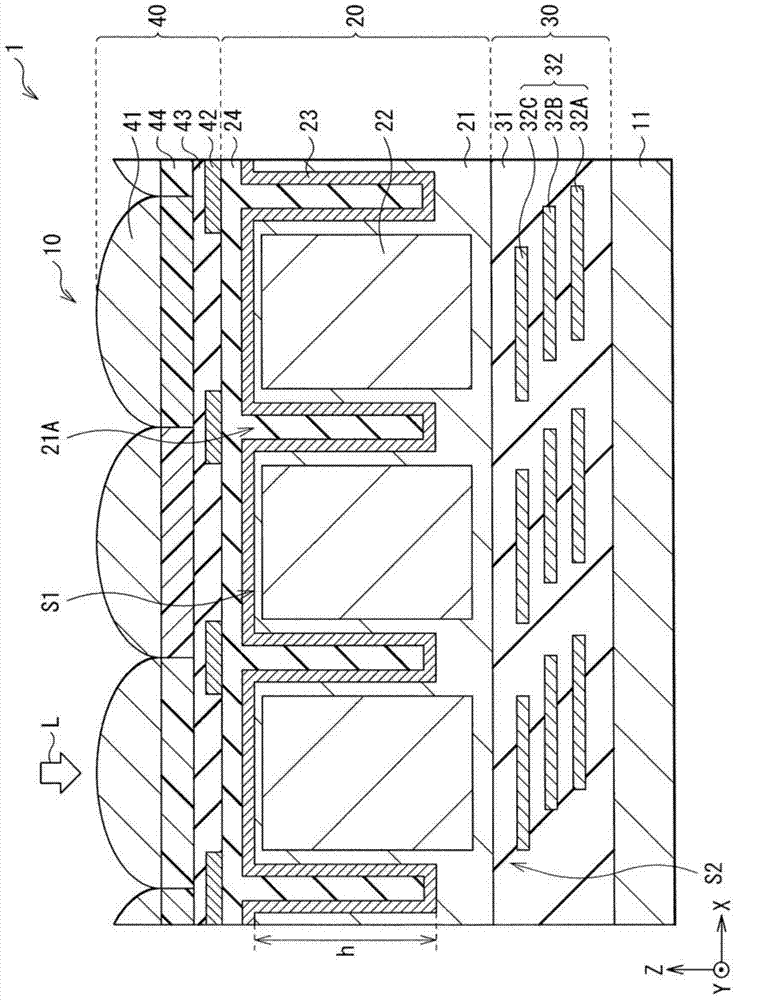

[0029] figure 1 A cross-sectional configuration of an image pickup element (image pickup element 10 ) according to an embodiment of the present disclosure is shown. The image pickup element 10 may constitute, for example, one pixel (for example, pixel P) in an image pickup device (image pickup device 1) such as a CCD image sensor and a CMOS image sensor (see Figure 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com