Method for forming self-aligned metal silicide

A technology of metal silicide and metal silicide layer, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of negative drift of threshold voltage and poor NBTI performance, so as to reduce defects and improve NBTI performance , reduce or avoid the effect of surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

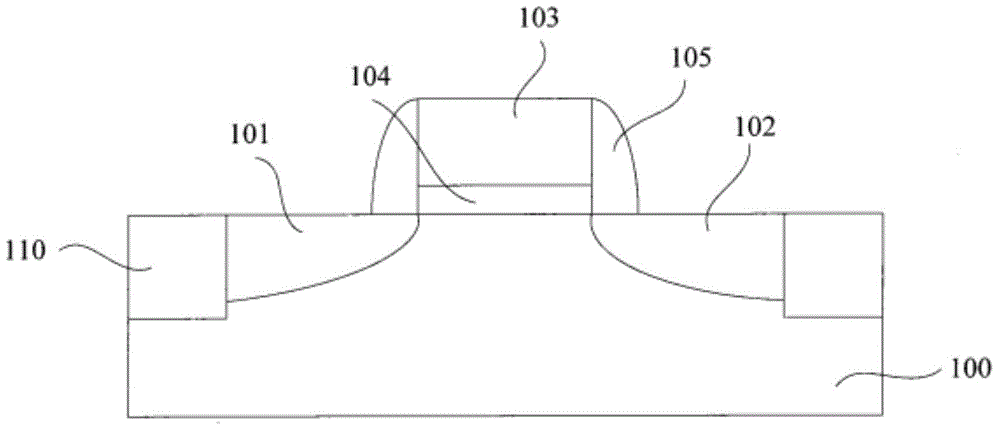

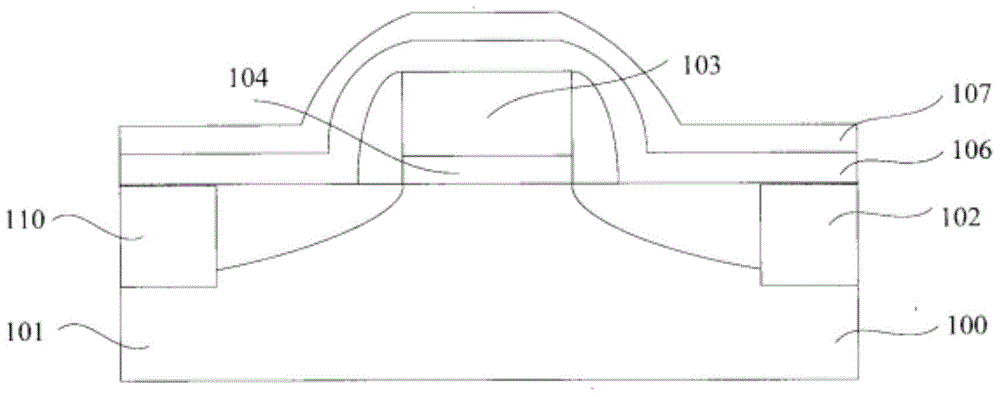

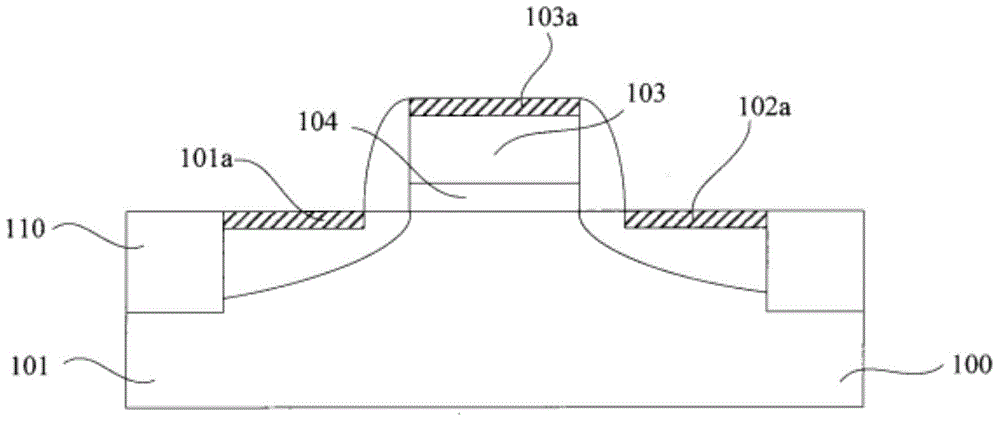

[0033] The embodiment of the present invention uses existing commonly used Ni as the material for forming metal silicide, and is based on a two-step annealing process, combined Figure 4 to Figure 5 Interprets the improvements of the technical solution of the present invention in detail, but the technical solution of the present invention is not limited thereto.

[0034] The method for forming a self-aligned metal silicide of this embodiment includes the following steps:

[0035] Step 1, such as Figure 4 As shown, a semiconductor substrate 11 is provided. The surface of the substrate 11 has a silicon region. The silicon region includes a source region 13 and a drain region 14 formed in the substrate 11 on both sides of the gate 12 and the gate 12 of the MOS transistor. The gate 12 includes a gate dielectric layer 121, a gate electrode layer 122, and sidewall spacers 123 formed on both sides of the gate dielectric layer and the gate electrode layer.

[0036] Before depositing the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com