Pig slaughtering system

A technology for live pigs and pork, applied in the direction of slaughtering, slaughtering accessories, slaughtering devices, etc. It can solve the problems of no pre-killed pigs resting and testing equipment, no feeding, only the right amount of water, and the pig's head is not clean enough to achieve good quality Suffocation effect, improvement of meat quality, and the effect of avoiding water waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

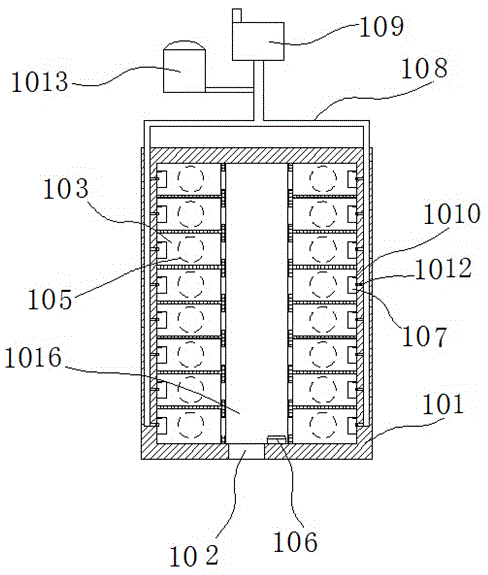

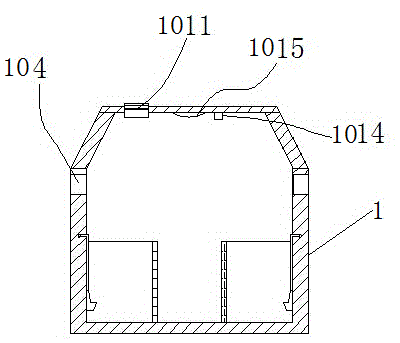

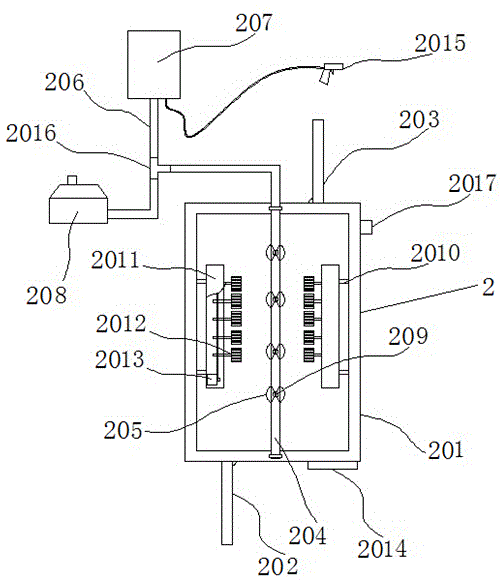

[0067] Such as Figure 1 to Figure 19 As shown, a pig slaughtering system of the present invention includes a lounge 1 for pre-killing pigs, a pig spraying room 2, a carbon dioxide suffocation room 3, an automatic pig scalding pool 4, cleaning and cooling equipment 5, and a hanging killing system connected in sequence. Pig opening machine 6, special burning pig hair equipment 7, pork automatic dividing machine 8, special storage box for pork 9, special equipment for packaging pigs 10;

[0068] The rest room 1 for the pre-killed pigs is used for rest and detection dedicated to the pre-killed pigs before slaughter;

[0069] The pig spraying room 2 is used for cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com