Processing method for summer and autumn congou black tea

A processing method, the technology of Gongfu black tea, which is applied in the field of tea processing, can solve the problems of unpicked spring tea and waste of fresh leaf resources, and achieve the effects of reducing bitterness, enhancing clarity, and excellent black tea quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

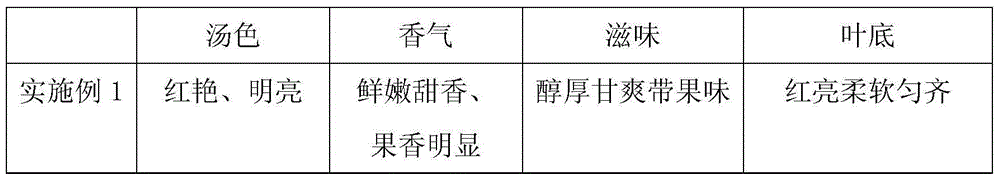

Examples

Embodiment 1

[0031] 1. Acceptance of fresh leaves

[0032] Fresh leaves with one bud and one leaf are selected as raw materials. According to the size of the buds and leaves, the wind sorting machine is used to sort the grades. The buds and leaves of the same grade are uniform, fresh, free of impurities and rotten leaves.

[0033] 2. Compound withering

[0034] The first stage: After the leaves are harvested, wither naturally indoors, the indoor environment is cool and ventilated, the temperature is 23°C-25°C, and the tea leaves are spread to dry on the green cloth or bamboo mat with a thickness of 2cm for 24 hours.

[0035] The second stage: Withering in the sun, thinly spread the fresh leaves on the bamboo mat, the thickness of the leaves is 1cm, the time is from 8:30 am to 12:30 noon, a total of 4 hours, the temperature is 27°C-29°C, and the leaves are turned in the middle 1-2 times, turn the leaves lightly so as not to damage the leaves, sun until the leaves are soft, the leaves are c...

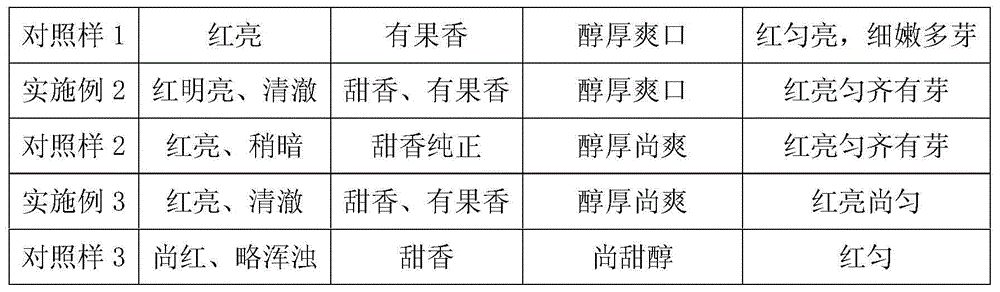

Embodiment 2

[0049] 1. Acceptance of fresh leaves

[0050] Fresh leaves with one bud and two leaves are selected as raw materials. According to the size of the buds and leaves, the wind sorting machine is used to sort the grades. The buds and leaves of the same grade are uniform, fresh, free of impurities and rotten leaves.

[0051] 2. Compound withering

[0052] The first stage: After the leaves are harvested, wither naturally indoors, the indoor environment is cool and ventilated, the temperature is 23°C-25°C, and the tea leaves are spread to dry on the green cloth or bamboo mat with a thickness of 3cm for 12 hours.

[0053] The second stage: Withering in the sun, thinly spread the fresh leaves on the bamboo mat, the thickness of the leaves is 1cm, the time is from 13:30 noon to 16:30 pm, a total of 3 hours, the temperature is 31°C-32°C, and the leaves are turned in the middle 1-2 times, turn the leaves lightly so as not to damage the leaves, sun until the leaves are soft, the leaves ar...

Embodiment 3

[0065] 1. Acceptance of fresh leaves

[0066] Fresh leaves with one bud and three or four leaves are selected as raw materials. According to the size of the buds and leaves, the wind sorting machine is used to sort the grades. The buds and leaves of the same grade are uniform, fresh, free of impurities and rotten leaves.

[0067] 2. Compound withering

[0068] The first stage: After the leaves are harvested, wither naturally indoors, the indoor environment is cool and ventilated, the temperature is 23°C-25°C, and the tea leaves are spread to dry on the drying cloth or bamboo mat, the leaf thickness is 4cm, and the time is 24h.

[0069] The second stage: Withering in the sun, thinly spread the fresh leaves on the bamboo mat, the thickness of the leaves is 1cm, the time is from 10:00 to 12:00, a total of 2h, the temperature is 31°C-32°C, and the leaves are turned 1- 2 times, turn the leaves lightly so as not to damage the leaves, sun until the leaves are soft, the leaves are cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com