Fingerstall type ultrasonic probe

An ultrasonic probe and finger cot technology, which is applied in the field of medical devices, can solve the problems of cumbersome operation, puncture errors, and failure to effectively reflect the effect of the ultrasonic probe, and achieve the effect of large detection area, convenient use, and improved puncture success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

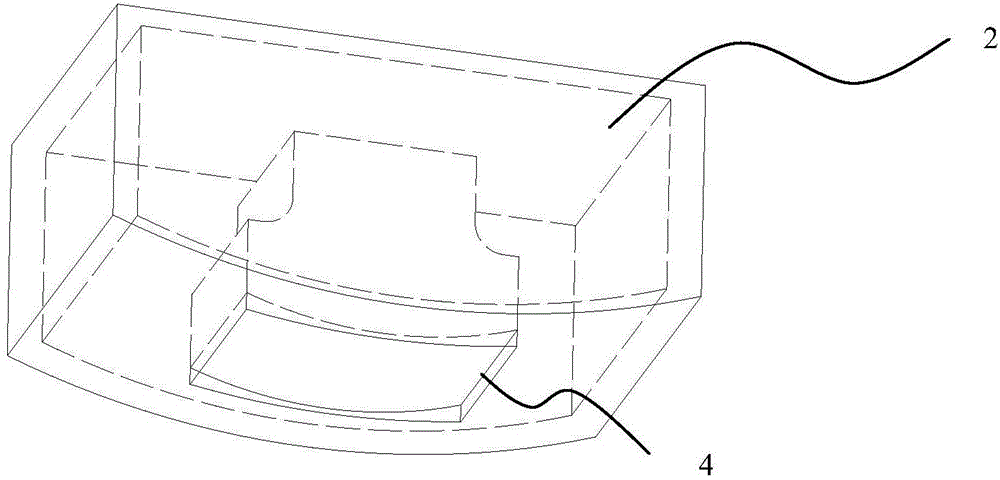

[0030] A finger cot type ultrasonic probe includes a shell, a transducer 4 and other accessories related to the transducer. The shell is composed of a finger cot 1 and a casing 2 . The fingertip is a cylinder with through holes inside. The fingertip 1 has a double-layer structure, the outer layer is made of a material with a certain hardness, and the inner layer is relatively soft. The casing 2 is located on the outside of the outer circle of the finger cot 1. When the finger is inserted into the finger cot 1, the casing will be on the fingertip. There is a cavity inside the casing 2, the top is not closed, and the bottom has a hole. The side wall of the casing 2 is connected with the finger cot by bolts. The transducer 4 and related accessories are installed inside the casing 2, wherein the acoustic window 41 of the transducer 4 corresponds to the hole 21 on the casing 2, and the acoustic window 41 can pass through the hole 21 to contact the body surface for feedback signal ...

Embodiment 2

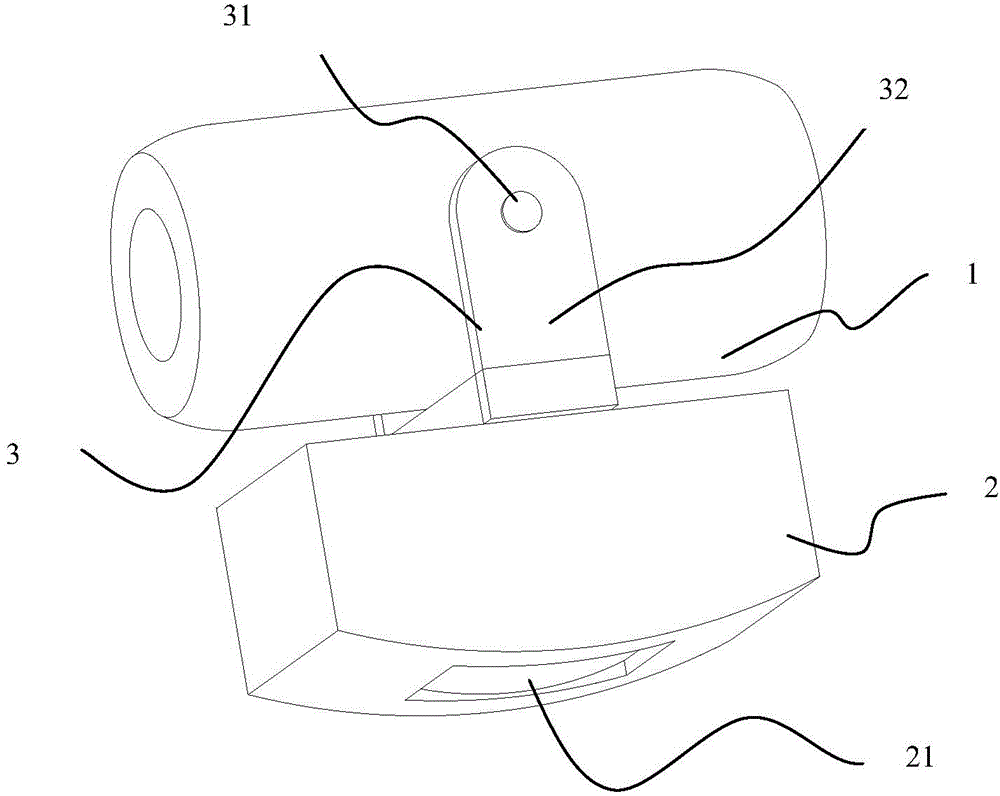

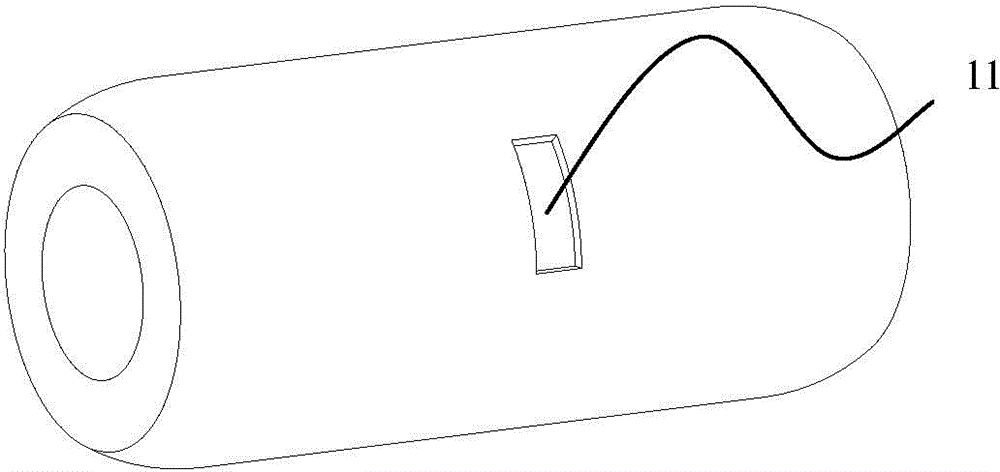

[0032] Such as Figure 1 ~ Figure 3 As shown, a finger-sleeve ultrasonic probe, the rest is the same as that of Embodiment 1, the housing also includes a connecting device 3, and the top of the housing 2 is closed. The connecting device 3 is a slider 31 and a slider seat 32 , the slider 31 is installed in the slider seat 32 , and the slider seat 32 is fixed on the top of the casing 2 . There are two slideways 11 distributed on both sides of the fingertip in the circumferential direction relative to the mirror surface of the casing 2. After the slider 31 on the connecting device 3 is engaged with the slideway 11, the connecting device 3 and the casing 2 can be formed around the fingertip. Circumferential movement. The angle formed between the two ends of the slideway 11 and the axial direction of the finger cuff is 15°, so the angle at which the casing 2 moves around the finger cuff 1 in the circumferential direction is 15°, which meets the needs of general testing.

Embodiment 3

[0034] Such as Figure 4 , Figure 5 A finger-sleeve ultrasonic probe is shown, and the rest are the same as in Embodiment 1, and the object includes a connecting device 3 . The connecting device 3 is a universal joint, and two universal joint forks of the universal joint are respectively connected with the finger cot 1 and the casing 2 , wherein the connection with the casing 2 is completed by means of a connecting shaft 33 . Through the connection of the universal joint, the ultrasonic probe can complete the circumferential movement around the fingertip and the forward and backward movement. Both ends of the finger cuff 1 are smooth curved surfaces, and the intersection of the side of the casing 2 and the finger cuff 1 is relatively smooth, so that the freedom of the ultrasonic probe in two directions can not be hindered. There are two stoppers 12 on both sides of the upper circumferential direction of the fingertip 1 which are mirror images of the casing 2. The stoppers 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com