A high-pressure-resistant separation filtration membrane column device with a low-resistance deflector

A technology of separation and filtration and high pressure resistance, which is applied in the fields of semi-permeable membrane separation, membrane technology, osmosis/dialysis water/sewage treatment, etc. It can solve the problems of failure of filtration effect, deformation, damage and deterioration of lip seal ring, etc., to reduce the occurrence of Risk of displacement, reduced chance of liquid leakage, effect of reduced resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

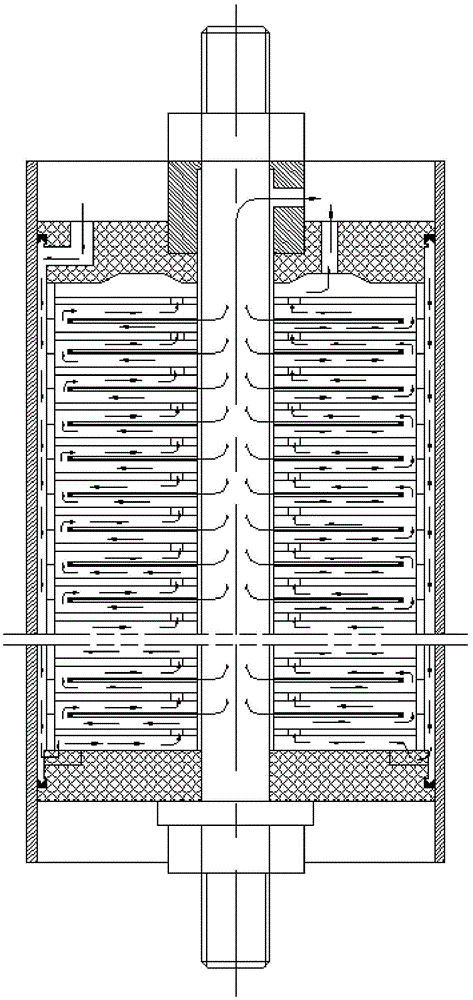

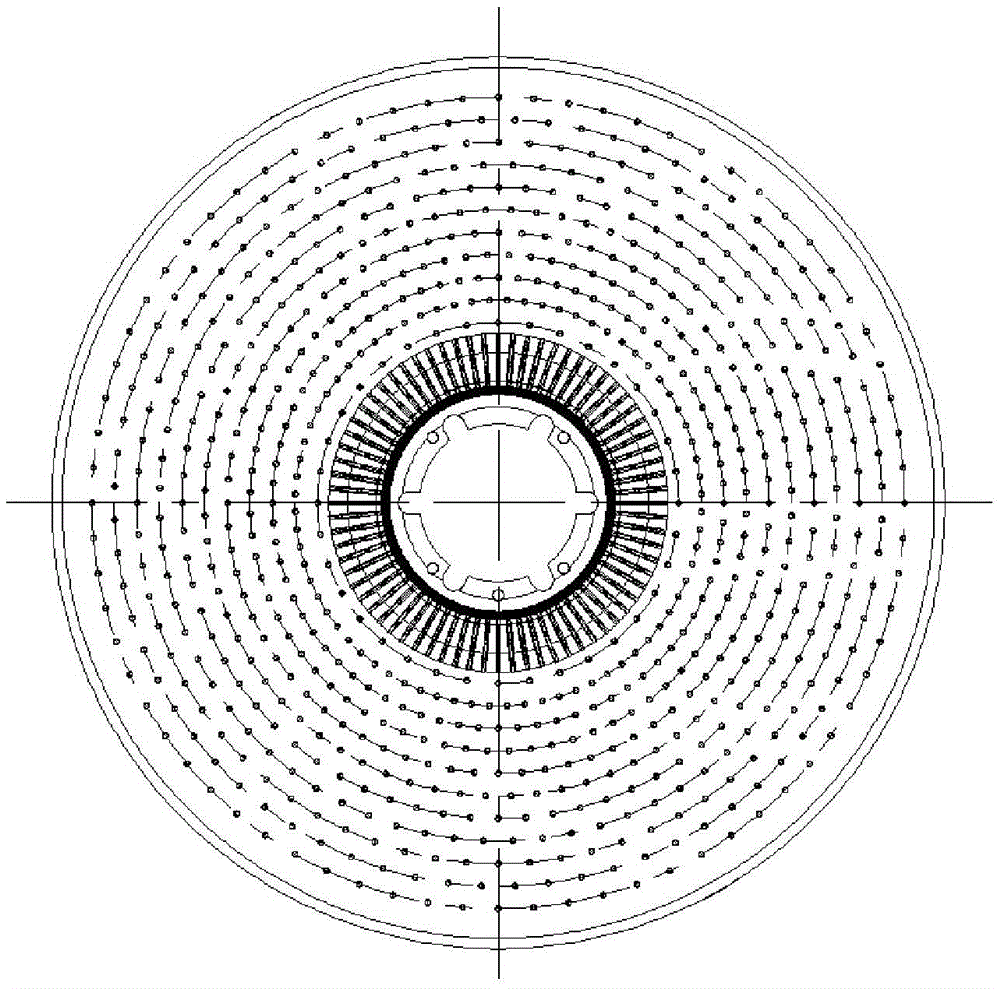

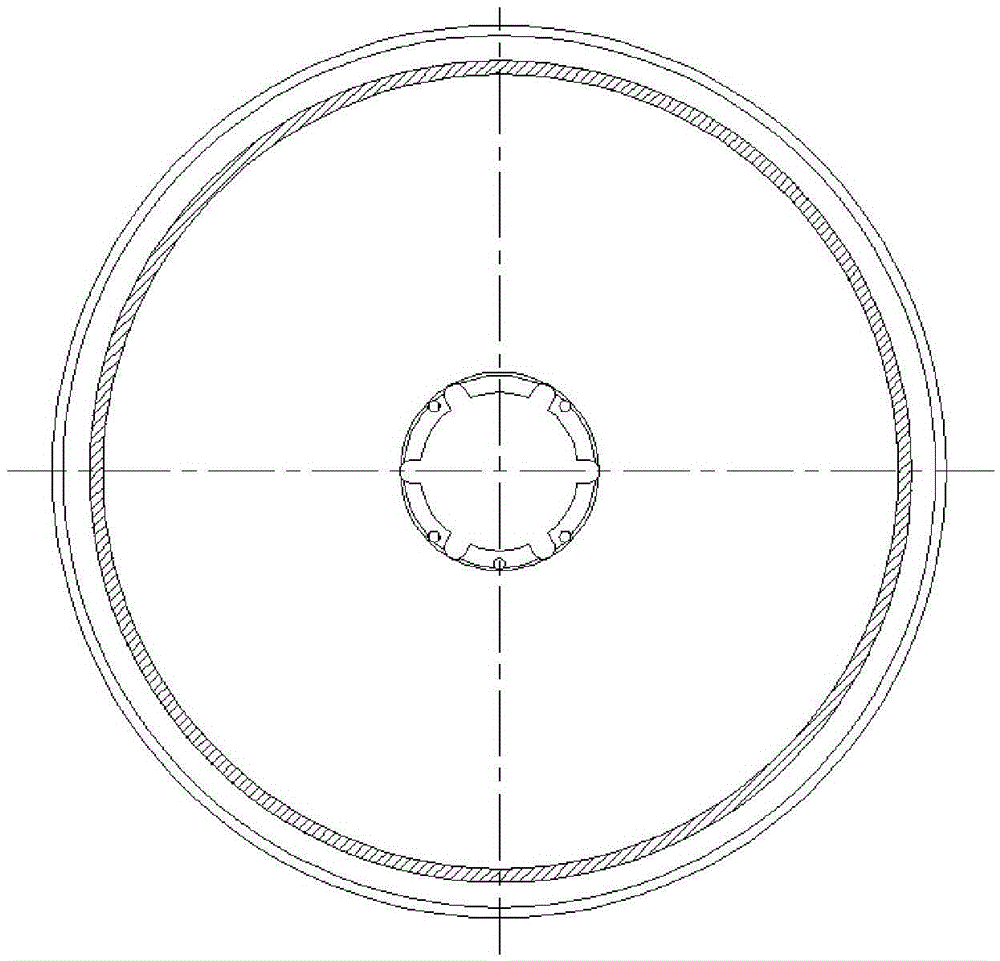

[0036] Such as Figure 4 , 5 As shown, a high-pressure separation filtration membrane column device with a low-resistance deflector plate includes a deflector plate 1, a diaphragm 2, and a circular tube-shaped pressure-bearing shell 3, and the two ends of the pressure-bearing shell 3 are flange structures.

[0037] The central opening of the guide plate 1 and the diaphragm 2, multiple guide plates 1 and diaphragms 2 are stacked alternately to form a membrane stack with a central opening, that is, the diaphragm 2 is sandwiched between two adjacent guide plates 1 , only without diaphragms on the deflectors at both ends. The outer diameter of the membrane stack is smaller than the inner diameter of the pressure housing 3, and the gap between them is the raw water channel 4 of the membrane column.

[0038] The two ends of the membrane stack are respectively provided with a terminal sealing plate 5 and a connecting end sealing plate 6. The central opening of the terminal sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com