Endotoxin adsorbent used in hemoperfusion, and preparation method thereof

A blood perfusion and endotoxin technology, applied in chemical instruments and methods, other chemical processes, dialysis systems, etc., can solve problems such as low ability to absorb endotoxin, avoid harmful substances residue, increase epoxy group content, improve effect of reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

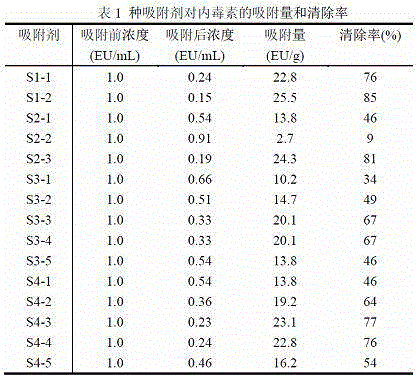

Image

Examples

Embodiment 1

[0046] The preparation process of the polymethacrylate adsorbent of the present embodiment is as follows:

[0047] 1-1 Polymethacrylate adsorbent

[0048] 1-1-1 prepare porous carrier;

[0049] Prepare polymethyl methacrylate resin, which is prepared by suspension polymerization, with a pore size of 5-50 nm and a specific surface area of 600 m 2 / g, the residual double bond content is 1.2mmol / g.

[0050] 1-1-2 Epoxy modification

[0051] Take 10g of polymethyl methacrylate resin, add 40mL of dichloroethane to soak overnight, then add 20mL of 1% m-chloroperoxybenzoic acid in dichloroethane dropwise, place in an ice-water bath (the temperature is controlled at 0~ 4°C) Stir the reaction for 24h at a rotation speed of 200rpm. After the reaction was completed, it was washed with alcohol and purified water; an epoxy-modified polymethyl methacrylate resin was obtained, and the epoxy group content of the resin was tested to be 0.7 mmol / g.

[0052] 1-1-3 Immobilized Ligands (Pol...

Embodiment 2

[0070] The preparation process of the polystyrene divinylbenzene resin adsorbent of the present embodiment is as follows:

[0071] 2-1 Prepare a porous carrier;

[0072] Prepare polystyrene divinylbenzene resin, using divinylbenzene with a purity of 80wt%, and prepare it by suspension polymerization. The obtained resin has a pore size of 5-50nm and a specific surface area of 800m 2 / g, the residual double bond content is 2.1mmol / g.

[0073] 2-2 Epoxy modification

[0074] Take 10g of polystyrene divinylbenzene resin and add 40mL of dichloroethane to soak overnight, then add 20mL of 1% m-chloroperoxybenzoic acid in dichloroethane dropwise, and put it in an ice-water bath (the temperature is controlled at 0~4 °C) Stir the reaction for 24 hours at a rotation speed of 200 rpm. After the reaction is completed, wash with alcohol and purified water. An epoxy-modified polymethyl methacrylate resin was obtained, and the epoxy group content of the resin obtained by testing was 1.3...

Embodiment 3

[0083] The preparation process of the polystyrene divinylbenzene resin adsorbent of the present embodiment is as follows:

[0084] 3-1 Preparation of Porous Support

[0085] Prepare polystyrene divinylbenzene resin, using divinylbenzene with a purity of 80wt%, and prepare it by suspension polymerization. The obtained resin has a pore size of 5-50nm and a specific surface area of 800m 2 / g, the residual double bond content is 2.2mmol / g.

[0086] 3-2 Graft modification

[0087] 3-2-1 grafted vinyl acetate

[0088] Take 10g of polystyrene divinylbenzene resin, add 50mL of 95% alcohol solution of 1.5% vinyl acetate, and 0.12g of dibenzoyl peroxide. Start stirring speed 200rpm. The reaction was carried out at 70° C. for 4 hours. After the reaction is completed, wash with alcohol and purified water.

[0089] 3-2-2 grafted vinylpyrrolidone and hydroxyethyl methacrylate

[0090] Take 10g of polystyrene divinylbenzene resin, add 1% vinylpyrrolidone, 50mL of 95% alcohol solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com