slope drying yard

A technology for slopes and stockyards, applied in the field of slope drying yards, can solve the problems of occupying the site, achieve convenient operation, alleviate the shortage of industrial land supply and demand, and reduce manpower consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings of the description.

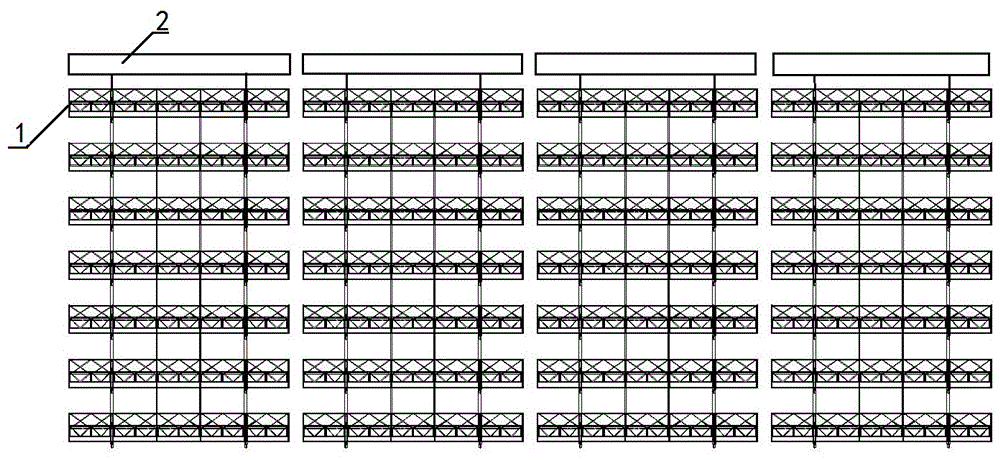

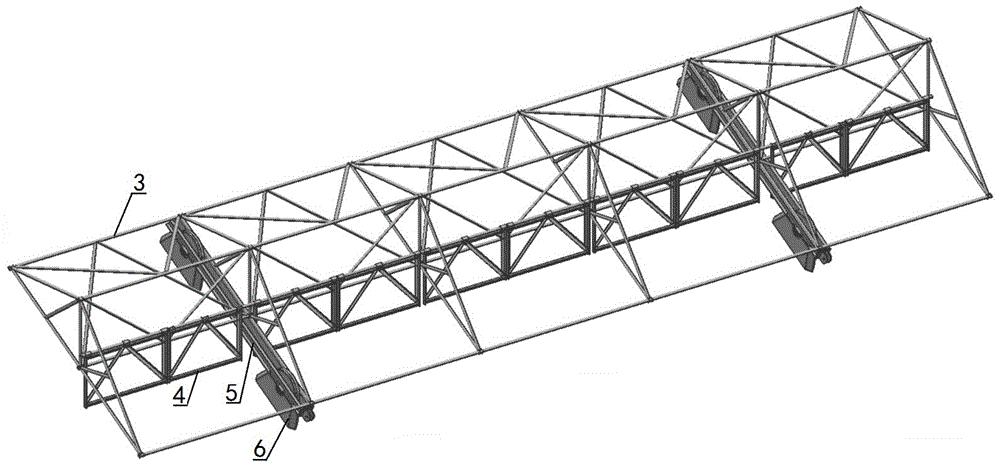

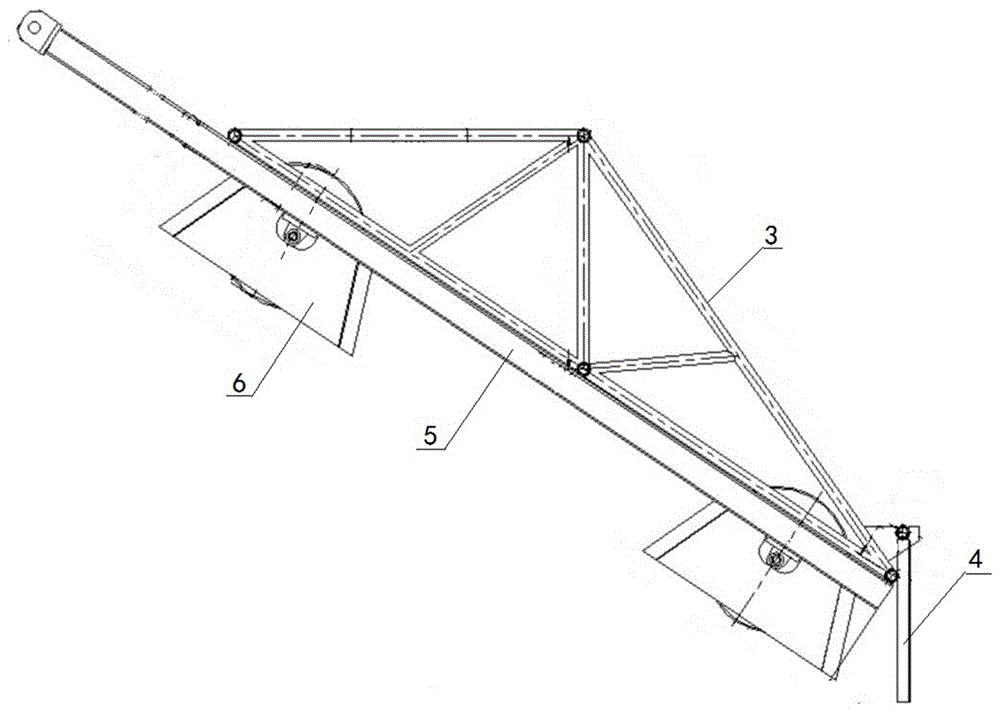

[0022] A slope drying yard, such as figure 1 As shown, it includes a scraping device 1 and a hoist 2. The scraping devices 1 are distributed in an array along the slope, and the scraping devices 1 in the same row are fixedly connected to each other and can move synchronously. Keep the same distance between the scraping devices 1 in the same row to avoid mutual interference and collision. The hoist 2 is arranged on the top of the slope, and the hoist 2 is connected with the scraping device 1 arranged longitudinally. The hoist 2 drives the longitudinal scraping device 1 to move synchronously through the wire rope, and the material at the top of the slope is gradually pushed to the bottom of the slope through the reciprocating motion of the scraping device 1 . The electric motor in the winch 2 can automatically control the scraping device 1 to execute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com