Electric heating furnace for preparing graphene

An electric heating furnace and graphene technology, applied in the field of electric heating furnaces, can solve the problems of waste acid, waste water environmental pollution, expensive chemical vapor deposition technology equipment, complicated processes, etc., and achieve low device cost, simple deposition process operation, and deposition good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

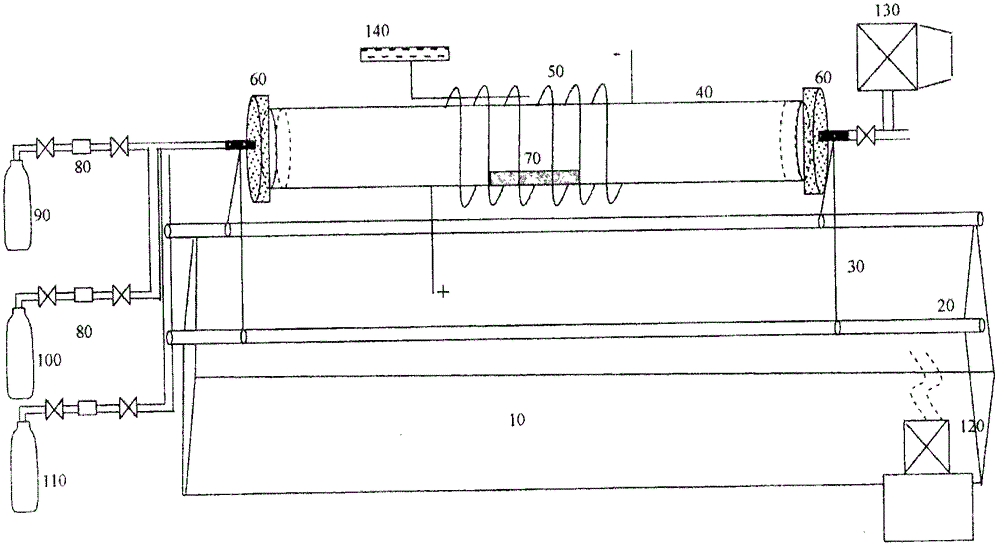

[0027] According to the attached figure 1 As shown, a high-quality quartz tube with a length of 1 m was selected as the deposition furnace, the iridium sheet was used as the carrier material, and the size was 10 mm × 10 mm × 0.5 mm. Before the graphene preparation, keep the vacuum inside the quartz tube. Turn on the power supply, heat the resistance wire, heat the temperature to 950°C, and keep a constant temperature; then open the intake valve, put in methane and hydrogen, and the flow rates are 100ml / min and 50ml / min respectively. Nitrogen rapidly cools the heating part of the furnace body, and at the same time quickly moves the slide rail to quickly cool the heating part to the liquid nitrogen sprayer, and finally obtains high-quality single-layer graphene on the platinum sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com