Insulation coating system and preparation method of insulated acupuncture needles

A coating system and acupuncture needle technology, applied in the direction of solid-state chemical plating, metal material coating technology, coating, etc., can solve problems affecting acupuncture effects, current leakage, etc., achieve great commercial promotion value, prevent corrosion, and improve preservation and the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

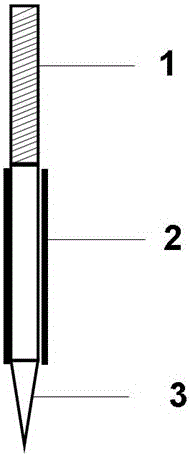

[0016] The first aspect of the present invention proposes coating an insulating layer on specific parts of traditional stainless steel acupuncture needles, so that the other parts except the needle handle (for external current input) and the needle tip (for current to enter the acupuncture points or affected parts of the human body) are coated with an insulating layer. layer of high-precision insulating material. The thickness of the insulating layer is between 100 nanometers and 100 microns, and the typical thickness is several microns; it can have a good insulating effect on voltages up to 220 volts in the frequency range of 0 to 300 Hz, and the leakage current is less than 1 microampere.

[0017] The second is a method and system for coating an insulating layer by using a targeted optimized sol-gel method. The method includes the following steps:

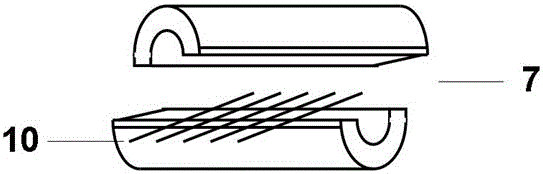

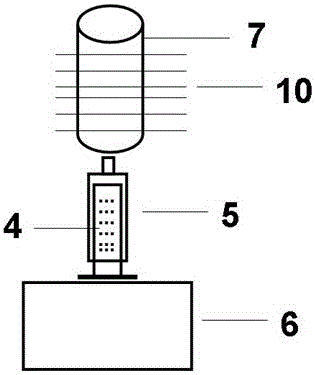

[0018] First, use titanium dioxide sol precursor 4, after homogenization, aging and other common precursor treatment processes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com