Wingless wall water gate arrangement mode

A sluice and form technology, applied in the field of wingless wall sluice layout form, can solve the problems of uneven settlement, increased investment, easy to be washed out, etc., and achieve the effect of reducing the amount of civil engineering, reducing the difficulty of construction, and convenient maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

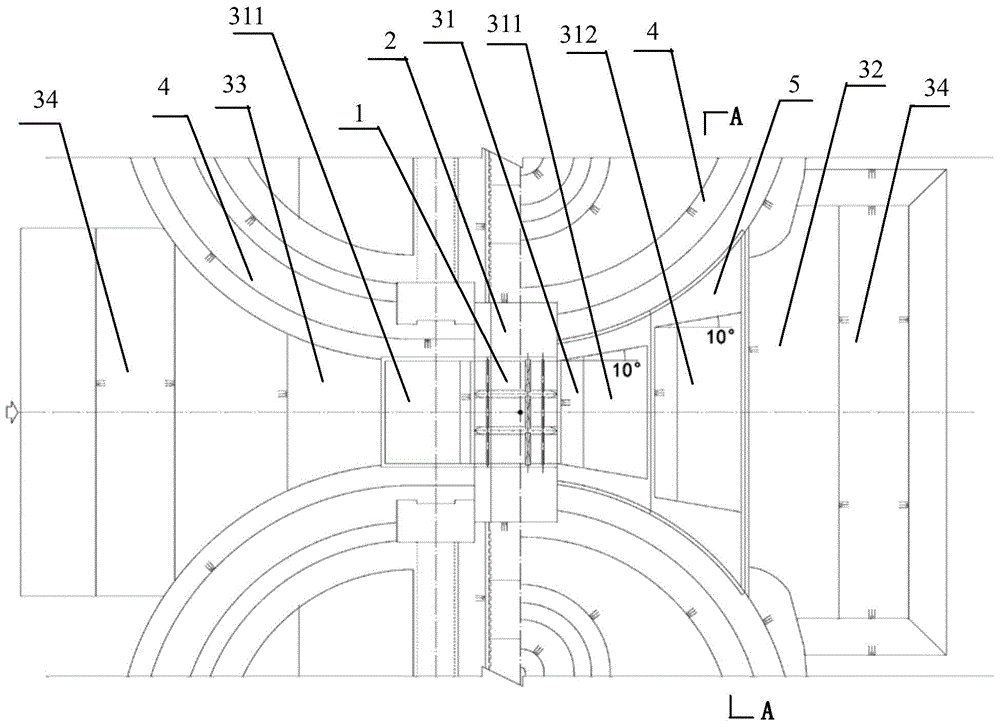

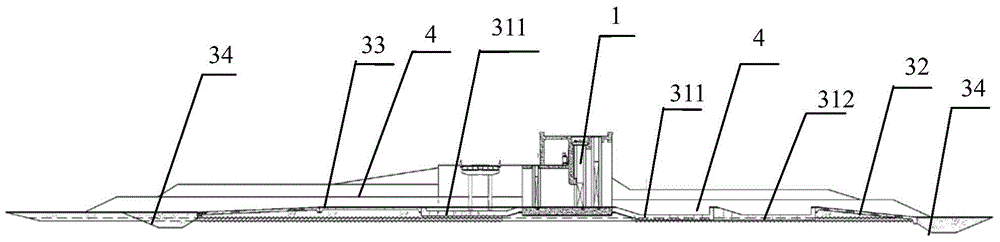

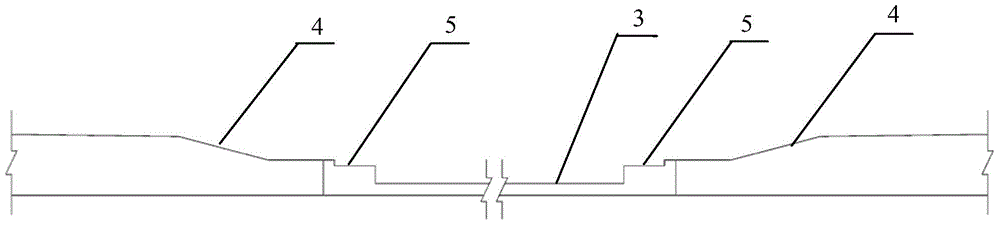

[0020] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, a wingless wall sluice layout form includes a lock chamber 1, a quay wall 2, an energy dissipation and anti-scour facility 3, a slope protection 4, and a concrete platform 5; the energy dissipation and anti-scour facility 3 includes a stilling pool 31, a sea diffuser 32. Bottom protection 33, anti-scouring groove 34; the stilling pool upstream of the lock chamber is provided with a primary stilling pool 311, and the stilling pool downstream of the lock chamber is provided with a primary stilling pool 311 and a secondary stilling pool 312; 1 The anti-scour trough 34, the bottom protection 33, and the primary stilling basin 311 are arranged in the upstream along the flow direction of the water in sequence, and the primary stilling basin 311, the secondary stilling basin 312, the seaman 32, and the anti-scour Slot 34. The left bank of the upstream of the sluice, the right bank of the upstream of the sluice, the ...

Embodiment 2

[0021] Embodiment 2: as Figure 4 As shown, a layout form of a wingless wall sluice includes a sluice chamber 1, a quay wall 2, an energy dissipation and anti-scour facility 3, a slope protection 4, a concrete platform 5, and a wing wall 6; the energy dissipation and anti-scour facility 3 includes Pool 31, sea mantle 32, bottom protection 33, and anti-scouring groove 34; anti-scouring groove 34, bottom protection 33, and primary stilling pool 311 are arranged in sequence along the flow direction upstream of the lock chamber 1, and primary stilling pool 311 is arranged in sequence along the flow direction downstream Pool 311, secondary stilling pool 312, sea diffuse 32, anti-scouring groove 34. The difference from Example 1 is that wing walls 6 are set on the left and right banks upstream of the sluice, and slope protection 4 is installed on the left and right banks downstream of the sluice without wing walls 6, and slope protection 4 is arranged against the bank wall 2, and sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com